November 29, 2016

7060-228G

17

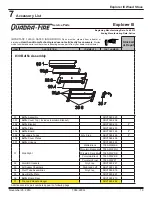

Explorer III Wood Stove

Convection

chamber top

Flue collar

Flue transition

Upper flue cover

Figure 17.3 - Completed View

Figure 17.1

E. Reversible Flue Collar and Horizontal Flue

Heat Shield

Tools Required:

#2 & #3 Phillips head screwdriver; 1/2"

wrench

The flue collar is reversible for either a top or rear venting

installation. The appliance is shipped with the flue collar in

the top vent position.

Converting Collar For Rear Vent Installation

and

Installing Required Horizontal Flue Shield

1. Remove flue collar (#3 Phillips) and convection chamber

top (#2 Phillips).

2. Remove 1 bolt from each side of the flue transition and

retrieve nuts attached to bolts.

3. Turn flue transition to horizontal position. Inspect rope

gasket to ensure a leak free seal. Re-attach.

4. Remove upper flue cover from convection chamber top.

Rotate 180 degrees and reassemble. Use paint supplied

to cover unpainted areas.

5. Reattach convection chamber top to flue collar to appli-

ance.

Figure 17.2

D. Optional Fire Screen

An optional fire screen is available for the Explorer III.

Optional Fire Screen Part SCR-7060 may be used ONLY in

U.S. residential installations. Follow all safety warnings to

prevent any hazards.

• Do not leave the fire unattended when the door is

unlatched or when using the fire screen.

• Unstable firewood could fall out of the firebox

creating a fire hazard to your home.

WARNING

Fire Risk.