18

7027-802K

10/21

C. General Maintenance and Cleaning

1.

Types of Fuel

The type of fuel you are burning will dictate how often you

have to clean your fire pot.

If the fuel you are burning has a high dirt or ash content, it

may be necessary to clean the fire pot more than once a

day.

Dirty fuel will cause clinkers to form in the firepot

(Figure 18.1)

. A clinker is formed when dirt, ash or a

non-burnable substance is heated to 2000°F (1093°C)

and becomes glass-like. See

High Ash Fuel Content

Maintenance

for more details on different types

of fuels.

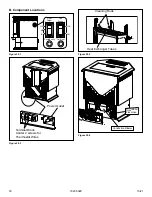

Back side of Firepot

Firepot floor left open

Figure 18.2

Clinker

Figure 18.1

NOTE:

If you are just cleaning the fire pot, there is no

need to unplug the insert.

3.

Ash Removal from Firebox

• Frequency:

Every 5 bags or weekly or more frequently

depending on ash build-up.

• By:

Homeowner

a. There must not be any hot ashes in the firebox during

cleaning so allow the appliance to completely cool.

The firebox ash should be removed every time the

exhaust path is cleaned. Frequent cleaning of the

ash in the firebox will help slow down the build-up of

ash in the exhaust blower and vent system.

b. Plug in your appliance, if unplugged, and turn the

thermostat on and immediately shut it off to start the

exhaust blower on its cycle time. It will pull fly ash out

the exhaust instead of into the room.

c. Open door. Remove ash with an ash vacuum or whisk

broom and small dust pan.

d. This ash is deposited in the same ash pan as the fire

pot debris. The ash pan should be emptied every time

you clean the firebox. Remember to place the ash

and debris into a metal or noncombustible container.

e. The cleaning rods must be fully closed when cleaning

is complete; see

Disposal of Ashes

4.

Cleaning Ash Pan

• Frequency:

Weekly or every 5 bags of fuel

• By:

Homeowner

Empty into a non-combustible container and re-install ash

pan; see

Disposal of Ashes

on

b. Pull fire pot cleaning rod OUT a couple of times to

help shake debris loose. If rod is hard to pull, it may

be necessary to use your fire pot clean-out tool to

chip away material that has built up on the bottom

plate of the fire pot and to push out any clinkers.

Larger clinkers may have to be removed from the top

of the fire pot.

c. The fire pot floor plate must be fully closed when

finished

(Figure 18.2)

.

2.

Cleaning Fire pot with Cleaning Rod & Fire pot

Scraper

• Frequency:

Daily or more often as needed

• By:

Homeowner

a. The appliance must be in complete shutdown and

cool and the exhaust blower off.

WARNING

Fire Risk

• NEVER pull fire pot cleaning rod or

cleaning slide plates out when appliance

is operating.

• The cleaning slide plates must be fully

CLOSED when appliance is operating.

• Hot pellets may fall into ash pan and start a fire or

mis-starts due to lack of vacuum.

Fire Risk

•

The cleaning slide plates must be fully

CLOSED when appliance is operating.

Hot pellets may fall into ash pan and start

a fire.

WARNING