Page 22

October 24, 2011

Castile & Santa Fe CE Pellet Stove

R

7068-112B

Do not terminate vent

in any enclosed or semi-enclosed

area such as a carport, garage, attic, crawl space, under a

sun deck or porch, narrow walkway or closely fenced area,

or any location that can build up a concentration of fumes

such as a stairwell, covered breezeway, etc.

CAUTION

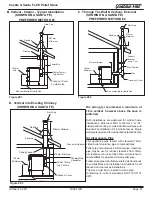

A. Venting Termination Requirements

1

.

Termination must exhaust above air inlet elevation.

It is

strongly recommended that at least 1.5m of vertical

pipe be installed when appliance is vented directly

through a wall.

This will create a natural draft, which

will help prevent the possibility of smoke or odor venting

into the home during a power outage. It will also keep

exhaust from causing a nuisance or hazard by exposing

people or shrubs to high temperatures. The safest and

preferred venting method is to extend the vent vertically

through the roof.

2

.

Distance from

doors and opening windows, or gravity or

ventilation air inlets into building:

a. Not less than 1.2m below;

b. Not less than 1.2m horizontally from;

c. Not less than 305mm above.

3

.

Distance from permanently closed windows;

a. Not less than 305mm below; horizontally from or

above.

4

.

Distance between

bottom of termination and grade should

be 305mm minimum. This is conditional upon plants in

the area, and nature of grade surface. The grade sur

-

face must be a non-combustible material (i.e., rock, dirt).

The grade surface must not be lawn. Distance between

bottom of termination and public walkway should be

2.13m minimum.

5

.

Distance to combustible

materials must be 610mm

minimum. This includes adjacent buildings, fences,

protruding parts of the structure, roof overhang, plants

and shrubs, etc.

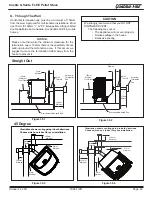

6. Termination Cap Location (Home Electrical Service)

• Side-to-side clearance is to be the same as minimum

clearance to vinyl inside corners.

• Clearance of a termination cap below electrical service

shall be the same as minimum clearance to vinyl soffits.

• Clearance of a termination cap above electrical service

will be 305mm minimum.

• Location of the vent termination must not obstruct or

interfere with access to the electrical service.

7

Vent Information

B. Avoiding Smoke and Odors

Negative Pressure, Shut-Down and Electrical Power

Failure

To reduce the probability of back-drafting or burn-back in

the pellet appliance during power failure or shut down con

-

ditions, it must be able to draft naturally without exhaust

blower operation.

Negative pressure in the house will resist this natural draft if

not accounted for in the pellet appliance installation.

Heat rises in the house and leaks out at upper levels. This

air must be replaced with cold air from outdoors which flows

into lower levels of the house.

Vents and chimneys into basements and lower levels of the

house can become the conduit for air supply and reverse

under these conditions.

Outside Air

An outside air kit is recommended in all installations. The

Outside Air Kit must be ordered seperately.

Per your local building codes, consideration must be given

to combustion air supply to all combustion appliances.

Failure to supply adequate combustion air for all appliance

demands may lead to backdrafting of those and other appli

-

ances.

When the appliance is roof vented (strongly recommended):

The air intake is best located on the exterior wall ori

-

ented towards the prevailing wind direction during the

heating season.

When the appliance is side-wall vented:

The air intake is best located on the same exterior wall

as the exhaust vent outlet and located lower on the wall

than the exhaust vent outlet.

The outside air supply kit can supply most of the demands

of the pellet appliance, but consideration must be given to

the total house demand.

House demand may consume the air needed for the appli

-

ance. It may be necessary to add additional ventilation to

the space in which the pellet appliance is located.

Consult with your local heating professional to determine

the ventilation demands for your house.