www.aristospray.com

15

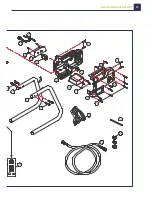

DAILY MAINTENANCE

1.

Keep the displacement pump

packing nut lubricated with Q-Lube

Piston Lubricant at all times.

Add

about five drops of oil to the top of the

pump at the beginning of each day.

Then two drops for every hour of

spraying. The lubricant helps protect

the piston, rod and packings.

2.

Inspect the packing nut daily.

If either

of the following conditions exists the

packing nut should be tightened:

a. Seepage of material past the

packing is found.

b. While the system is pressurized

during the intervals when the motor

is not running, the piston doesn't

hold its position. Rather, it tends to

slip upward.

To tighten the packing nut: Reach the

tommy bar through the opening and

tighten the packing nut.

CAUTION: The packing nut should be

tightened just enough to stop leakage

only, but not any tighter. Overtightening

will damage the packings and reduce

packing life.

3.

Clean the intake check ball and seat.

To clean:

1. Remove the suction tube (73) by

releasing the hose clip (71) and pulling

the hose free. Use a wrench to loosen

the gland nut.

2. Remove the check ball and ball guide

and clean all related parts.

3. Replace in the reverse of assembly and

tighten.

PUMP PACKINGS

The packings are a wearing part. If the

pump can no longer maintain pressure,

has diffculty priming and paint seeps into

the throat of the pump, and tightening the

packing nut no longer helps, then the

packings will require replacement. This is

best entrusted to a qualified repair

technician.

To remove the pump and replace the

packings, follow the instructions below:

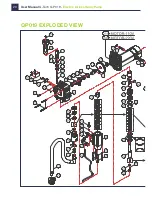

PUMP REMOVAL

1. Remove the suction tube by releasing

the hose clip and pulling the hose free.

2. Turn the pump until the piston is at its

lowest point. To do this, it is necessary

to remove the left side frame leg (77)

and then remove the 12 screws to

remove the left side motor housing

(38). Then the motor may be turned by

turning the fan from the rear.

3. Loosen and remove the 4 socket cap

screws (65)

4. Pull the pump forward to disengage

the displacement piston (53) from the

slot in the bottom of the drive piston

(45). (It must be at its lowest point in

order to disengage-see step 2 above)

5. The pump unit may now be lifted away.

6. Replacement is the reverse of removal.

Grease the junction slot of the drive

piston when assembling.

PACKINGS REPLACEMENT

1. Loosen the packing nut with the

tommy bar supplied and remove.

2. Pull out the piston.

3. Remove all parts and clean. Clamp the

displacement piston (53) in the soft

jaws of a vise and remove the ball seat

fastener (56) to allow removal of the

small ball seat (54) and the small check

ball.

4. Discard all old packings.

5. Soak the new leather packings in W30

oil for at least one hour before

assembling.