User Manual

Q-Tech Q-P019 -

Electric Airless Spray Pump

14

13. Without releasing the trigger, transfer

the gun to the flushing bucket and

allow the flushing fluid to recirculate for

2-3 minutes to make sure that all

traces of the material are cleaned out.

14. Turn off the machine and unplug. Open

the priming valve to relieve residual

pressure.

15. Remove the suction tube out of the

flushing fluid.

16. Clean the inlet strainer or hopper

strainer. Remove and clean it with a

soft brush in the appropriate solvent

and replace.

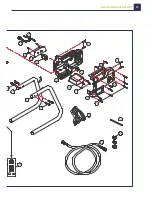

17. Clean the gun, tip, and gun filter.

unclip the hand guard and rotate it out

of the way. Then, using a wrench (not

supplied) loosen the nut on the bottom

of the handle and remove the handle to

remove the gun filter. Clean the tip and

filter with a soft brush in the

appropriate solvent. Apply a small

amount of light oil such as WD-40 to

the inside of the spray gun housing.

Place the filter in the spray gun and

reassemble the unit by tightening the

nut with the wrench.

18. Clean the exterior of the sprayer with a

rag soaked in the appropriate solvent.

19. If flushing was with water, flush again

with Q-Tector Pump Conditioner to

prevent corrosion inside the pump.

CAUTION: Never leave water in the

pump for any length of time. Water will

corrode the pump.

LONG TERM

STORAGE

For long- term storage, use Q-Tector

Pump Conditioner as directed on the

container.

To fill the pump:

1. Place the both the suction tube and

drain tube in a small quantity of

storage solution.

2. With the priming valve in the open

position, turn the machine on and turn

the pressure control knob just enough

for the pump to run.

3. Watch the drain tube and as soon as

the storage solution appears in the

tube, shut the machine off and close

the priming valve. This will trap the

storage solution inside the pump to

protect it.

MAINTENANCE

HOURLY MAINTENANCE

We recommend after every hour of

spraying, stop, follow the Pressure Relief

Procedure and perform the following:

•

Add about 2 drops of Q-Lube Piston

Lubricant to lubricate the packings.

•

Clean the pump filter, (if so equipped)

•

Clean the gun filter.

•

Clean the tip.

•

Clean the inlet strainer, as needed.

CAUTION: Never lay the pump on its

back. Material could flow backward and

damage the electronics or motor.