8.

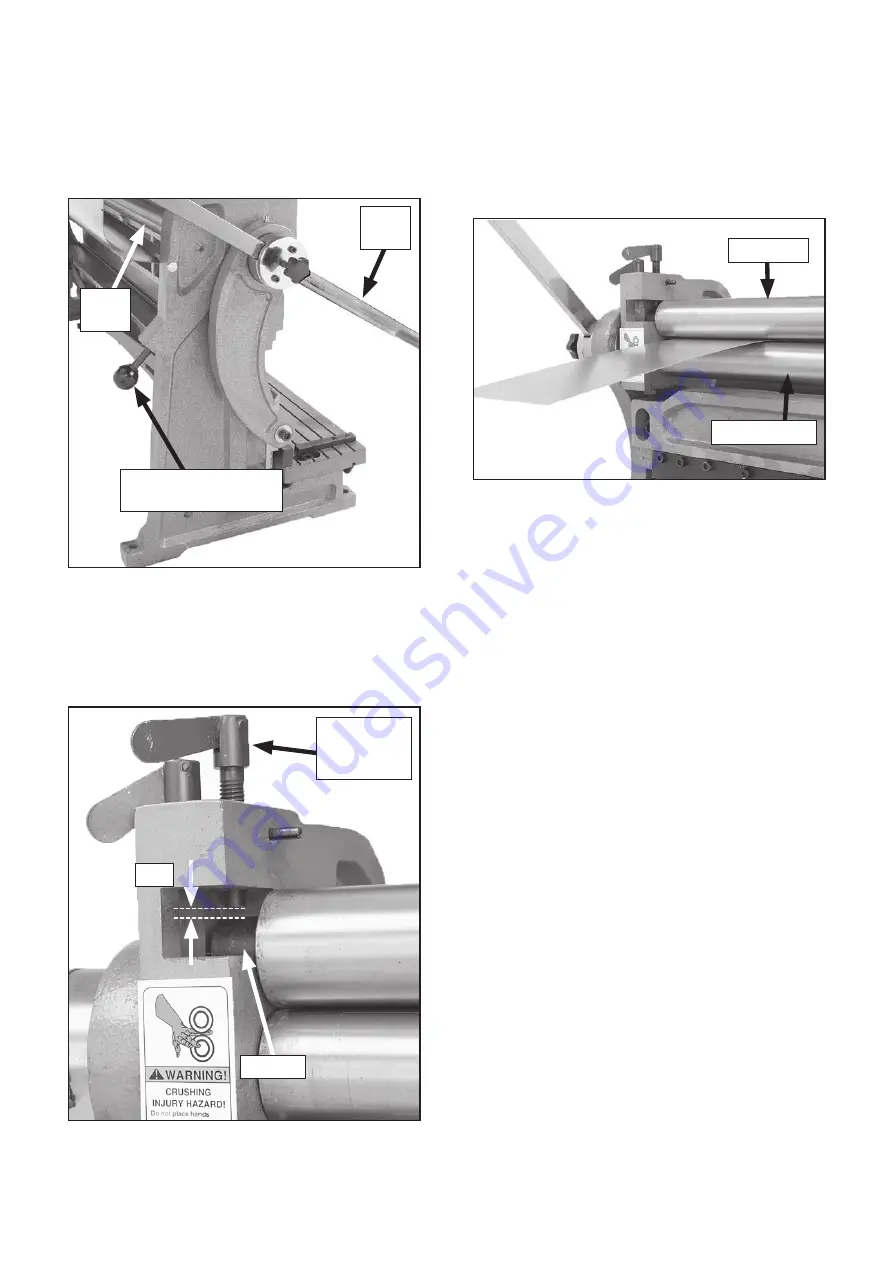

Unscrew the thickness adjustment leaf bolt

until the gap (Figure 7 ) between the leaf

bolt and the bushing is wider than the thick-

ness of the workpiece.

7.

Unscrew the diameter adjustment knobs

until the rear roller is backed-off completely

(Figure 6 ).

Figure 6

Diameter Adjustment

Knob

Work

Lever

Rear

Roller

Gap

Figure 7

Thickness

Adjustment

Leaf Bolt

9. While rotating the work lever, feed the sheet

metal between the top and bottom rollers

(Figure 8 ) until approximately 1-inch pro-

trudes through the other side.

10.

With the metal positioned between the top

and bottom rollers, tighten the thickness

adjustment leaf bolts until they are snug.

11.

Tighten the diameter adjustment knobs to

raise the rear roller a few millimeters to get

your initial bend setting.

Note: The heavier the gauge of metal, the

less aggressively you can adjust the rear

roller. With rigid metals such as aluminium,

you may have to leave the rear roller at the

lowest position and make more rolling repeti-

tions to achieve the needed bend radius.

Tip: To ease feeding the workpiece past the

third roller on the first rolling operation, use

the brake first to make a slight initial bend

in the workpiece, so the workpiece does not

butt up against the rear roller, but rather rides

up and over the roller.

Figure 8

Top Roller

Bottom Roller

Bushing

Summary of Contents for Bernardo 1320 S

Page 10: ...Parts Drawing for 3 in 1 1320mm ...

Page 12: ...Maschinen Austria ...