15

7.4

Connect a hand pump to the fitting on the outlet side of the system, and apply vacuum,

which serves to pull the barrier fluid through the system.

7.5

Attach the incoming barrier fluid supply under pressure to the inlet side and verify

that the needle valve is open.

7.6

WAIT…. The process will take time.

Higher pressure will not help and may

cause damage to the diaphragm

. Maintain pressure on the inlet side and

vacuum on the outlet side to move the fluid through the system.

7.7

Observe the fluid at the outlet (vacuum pump) side. When clear, air free fluid is

observed, close the inlet side needle valve and remove the pressure source.

7.8

Replace the plug into the needle valve to seal the system inlet.

7.9

Allow vacuum to remain on the outlet side of the system for approx. 2-3 minutes, this

will aid in the evacuation of excess fluid. Once complete, release the vacuum and

remove the hand pump.

7.10

Attach a short section of tubing to the fitting on the outlet side to catch excess fluid

as the system setup is completed in the next steps.

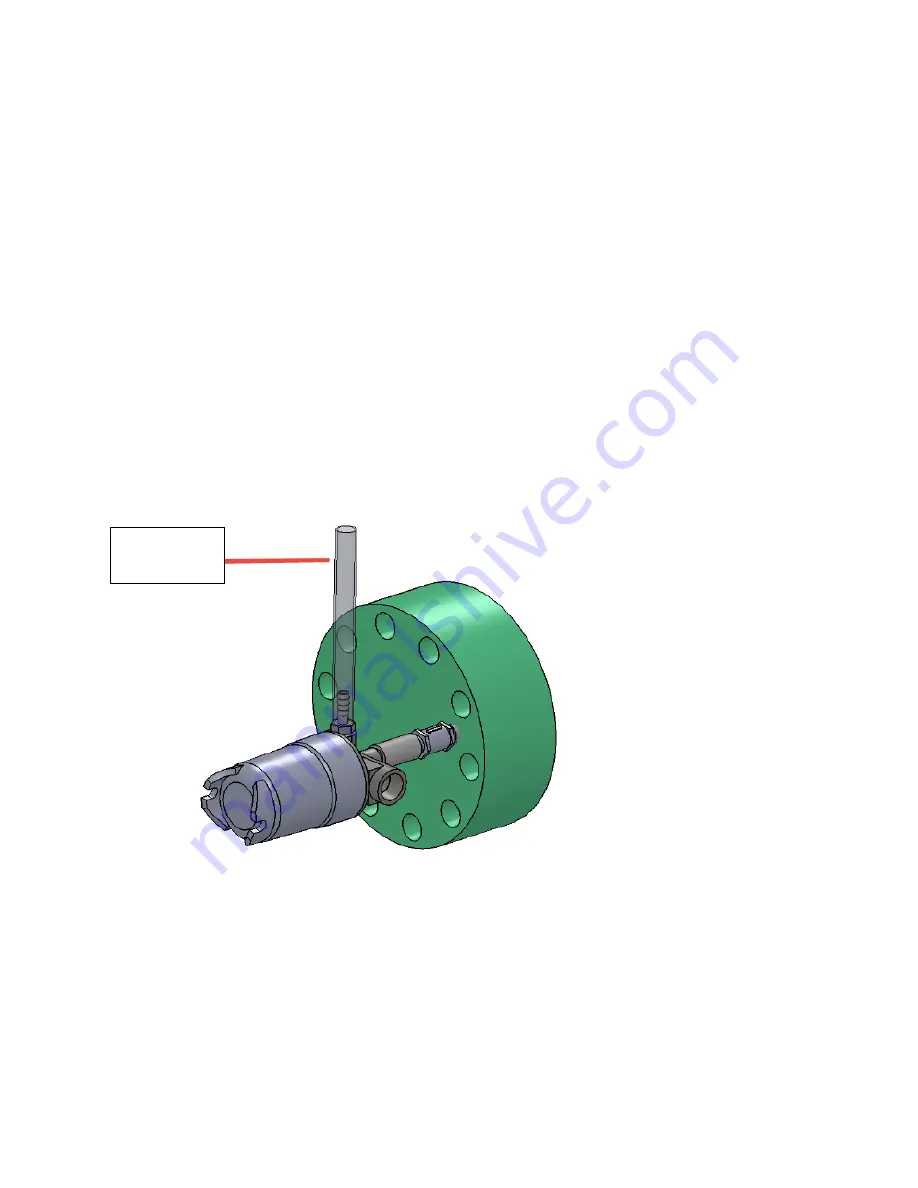

Figure 8 – bleed tubing

7.11

Ensure that the eccentric box of the pump has been filled to the appropriate level

with the correct hydraulic fluid.

7.12

If the pump is not already hydraulically primed

, re-prime it now using the

appropriate procedure for a standard Pulsa Series flat diaphragm pump. If the

diaphragm was never removed, this step should not be necessary. If a new

diaphragm is being installed, the pump will need to be re-primed.

Open to

atmosphere