/ŶƐƚĂůůĂƚŝŽŶ͕KƉĞƌĂƚŝŽŶĂŶĚDĂŝŶƚĞŶĂŶĐĞ DĂŶƵĂů

d>͘ϯϭ͘ϮϭϬͲ/KD͘E

^ĞĐƚŝŽŶϰ͗/ŶƐƚĂůůĂƚŝŽŶ

:ƵůϮϬϭϲ

/ŶƐƚĂůůĂƚŝŽŶ

ϭϯ

ϰ͘ϱ

Actuator to Valve Installation

Actuator must be isolated pneumatically and electrically before any (dis)assembly starts.

Stay away from moving parts to prevent serious injuries. When test cycling the actuator

and valve assembly by applying pressure to the A or B port, be aware that there are

moving parts like pinion top, actuator to valve coupling and the valve- blade, ball, plug,

etc.

The actuator is designed to be installed, commissioned and maintained using generic

tools like wrenches, Allen keys and screwdrivers. For the removal of inserts, a special

extractor tool can be supplied on request.

During assembly to the valve, do not hit with hammer on pinion top. This can damage

the pinion top washer and cause premature failure.

Before mounting the actuator on the valve or valve bracket, be sure that both

the actuator and the valve are in the same closed or open position.

Refer to appendix B, Tool and Torque tables, for using the right size tool

Table 7.

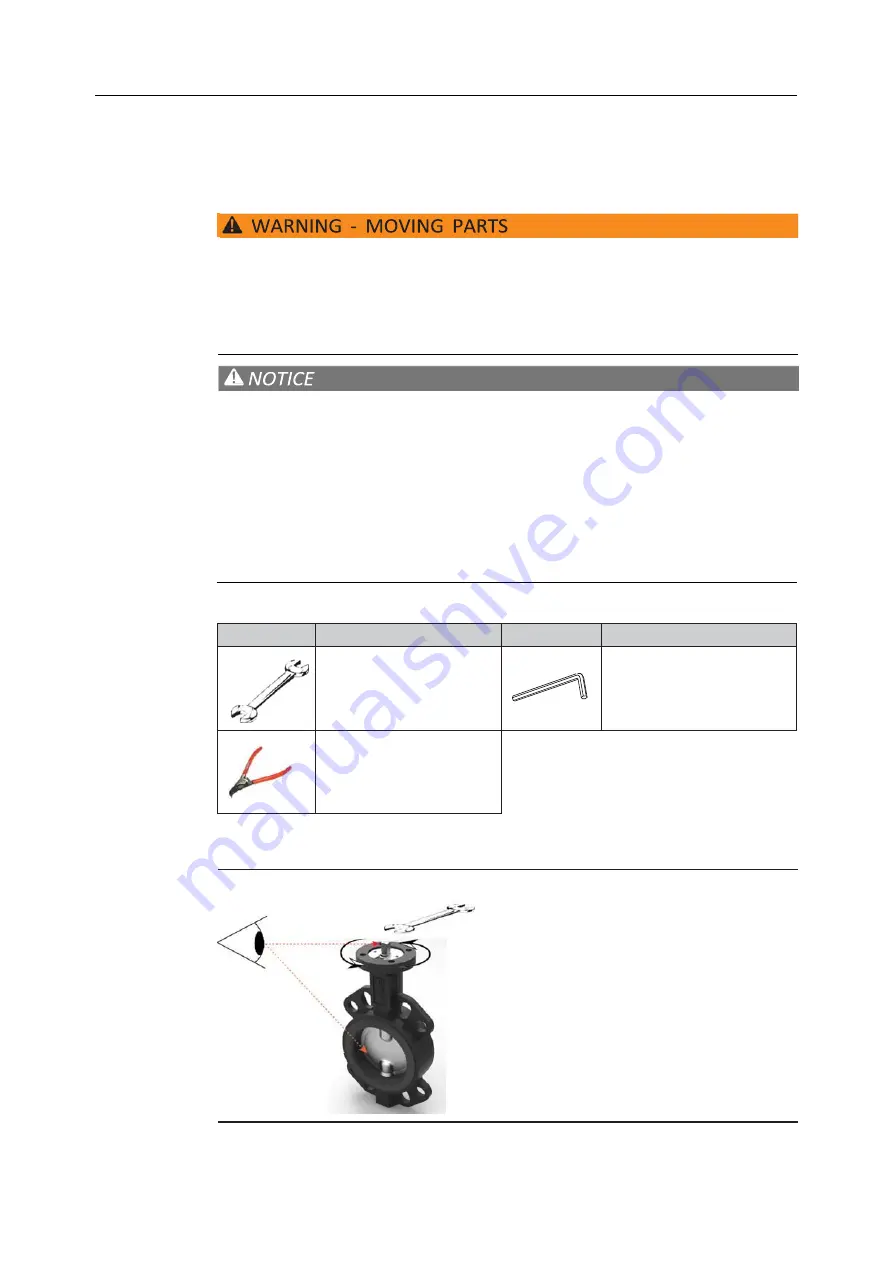

Tool Table

Symbol

Tool

Symbol

Tool

Wrench – All types and sizes.

Metric and Imperial

Allen key

Circlip Pliers

ϭ͘

Remove handle nut, handle, lock washer, and etc. from the valve if required.

Ϯ͘

Visually check to make sure the valve is CLOSED.

Figure 9

Valve handle removal