2

Table of contents:

1.

Description of the Mobile Man Anchor

..............................................................................................................................

2

2.

Construction of the Mobile Man Anchor

........................................................................................................................... .

3

3.

Technical data of the Mobile Man Anchor

....................................................................................................................... .

3

4.

Installation (mounting) of the Mobile Man Anchor

............................................................................................................

4

5.

Description of the labelling of the Mobile Man Anchor

.....................................................................................................

4

6.

Main rules for using the Mobile Man Anchor

....................................................................................................................

5

7.

Operating Sheet of the Mobile Man Anchor

......................................................................................................................

6

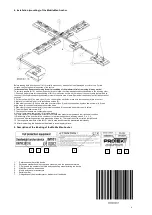

1. Description of the Mobile Man Anchor

The Mobile Man Anchor IM 101 was designed as a portable, collapsible anchorage point compliant with the EN 795:2012 standard type E. This

device helps protect employees working at heights, such as at the edge of a flat roof.

The Mobile Man Anchor allows you to quickly set up a safe and secure anchoring point for personal protective equipment for arresting falls from a

height. After the completion of the planned works the Mobile Man Anchor can be disassembled and transferred to another location, or stored until

its next use.

The modular design of the device allows it to be mounted and dismounted without the use of cranes, hoists, or any special equipment.

The weight of the individual components was chosen to make it compliant with the regulations (the weight of an individual item must not exceed 28

kg) and can be moved by man power.

The elements of the Mobile Man Anchor IM 101 are made of both rubber and steel. All steel components are made of stainless steel or are

protected against adverse weather conditions using hot galvanising, which ensures their durability up to 50 years.

The Mobile Man Anchor IM 100 can be used on the following types of surface:

- Bitumen

- PVC

with inclination angle not exceeding

5 ° .

Adequately large surface area taken up by the device can optimally distribute the load over the surface (e.g. a roof) to minimize the impact of the

load on the structure.

The Mobile Man Anchor shall not be used where there is a risk of frost, or in freezing conditions.

Remove any loose materials (e.g. lose stones) from the surface of the roof covering where the Mobile Man Anchor will be installed.

Do not use on icy, greasy or any slippery surfaces that may impair the Mobile Man Anchor's performance.

Device has to be placed at least 2,5m from the roof edge.

The IM 101 should be positioned to avoid areas where water accumulates.