SECTION 5

PRONAR T023, PRONAR T023M

5.25

Change of grease in hub bearings should be entrusted to specialised service points,

equipped with the appropriate tools. According to the recommendations of the axle

Manufacturer, dismantle the entire hub, remove the bearing and individual sealing rings. After

careful washing and inspection, mount lubricated elements. If necessary, bearing and seals

should be replaced with new parts. Lubrication of axle bearings shall be performed at least

once in 2 years.

TABLE 5.3

Lubrication schedule

ITEM

LUBRICATION POINT

N

U

M

B

E

R

O

F

L

U

B

R

IC

A

T

IO

N

P

O

IN

T

S

T

Y

P

E

O

F

G

R

E

A

S

E

F

R

E

Q

U

E

N

C

Y

1

Hub bearing

12

A

24M

2

Drawbar eye

1

B

14D

3

Handbrake mechanism

1

A

6M

4

Handbrake cable guide wheel axle

2

A

6M

5

Expander shaft slide sleeve

6

A

3M

6

Drawbar pin

2

B

3M

7

Leaf spring absorbers

6

C

3M

8

Leaf spring absorber sliding surfaces

6

B

1M

9

Leaf spring pin

6

B

1M

10

Rocker arm pin

6

B

1M

11

Turntable

2

B

3M

Lubrication periods – M months, D – days

(1) – grease every 3 months or each time before intensive work

TABLE 5.4

Recommended lubricants

Summary of Contents for T023

Page 4: ......

Page 8: ......

Page 9: ...SECTION 1 BASIC INFORMATION ...

Page 23: ...SECTION 2 SAFETY ADVICE ...

Page 33: ...SECTION 3 DESIGN AND OPERATION ...

Page 47: ...SECTION 4 CORRECT USE ...

Page 60: ...Pronar T023 Pronar T023M SECTION 4 4 14 ...

Page 61: ...SECTION 5 MAINTENANCE ...

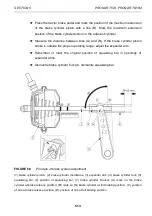

Page 87: ...SECTION 5 PRONAR T023 PRONAR T023M 5 27 FIGURE 5 12 Trailer s lubrication points ...

Page 97: ...NOTES ...

Page 98: ... ...

Page 99: ...ANNEX A TYRE WHEEL DISC 400 60 15 5 145A8 13 00x15 5 ET 15 360 65 16 148A8 11x16 ET 20 ...