PRONAR T023, PRONAR T023M

SECTION 5

5.18

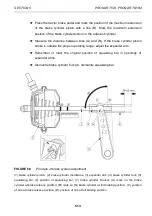

Prevent the trailer from rolling by placing chocks under the wheels. Immobilise

tractor and trailer with parking brake.

Start the tractor in order to supplement air in the trailer braking system tank.

In single line systems air pressure should amount to approx. 5.8 to 6.5

bar.

In double conduit systems air pressure should amount to approx. 5.8

bar.

Turn off tractor engine.

Check system components after releasing brake pedal in tractor.

Give particular attention to conduit connections and brake cylinders.

Repeat system check with depressed tractor brake pedal.

The help of a second person is required.

In the event of the appearance of leaks, compressed air will escape at the places of damage,

with a characteristic hiss. Lack of system tightness may be also detected by covering

checked elements with washing fluid or other foaming preparations, which will not react

aggressively with system components. It is recommended to supply preparations

commercially available designed to facilitate detecting air leaks. Damaged components

should be replaced or repaired. If leaks appear at connections then tighten the connections. If

air continues to escape, replace connection components or seals.

INSPECTION

•

After travelling the first 1,000 km.

•

Each time after making repairs or changing system components,

•

Every 12 months.

Summary of Contents for T023

Page 4: ......

Page 8: ......

Page 9: ...SECTION 1 BASIC INFORMATION ...

Page 23: ...SECTION 2 SAFETY ADVICE ...

Page 33: ...SECTION 3 DESIGN AND OPERATION ...

Page 47: ...SECTION 4 CORRECT USE ...

Page 60: ...Pronar T023 Pronar T023M SECTION 4 4 14 ...

Page 61: ...SECTION 5 MAINTENANCE ...

Page 87: ...SECTION 5 PRONAR T023 PRONAR T023M 5 27 FIGURE 5 12 Trailer s lubrication points ...

Page 97: ...NOTES ...

Page 98: ... ...

Page 99: ...ANNEX A TYRE WHEEL DISC 400 60 15 5 145A8 13 00x15 5 ET 15 360 65 16 148A8 11x16 ET 20 ...