EN|ENGLISH

9

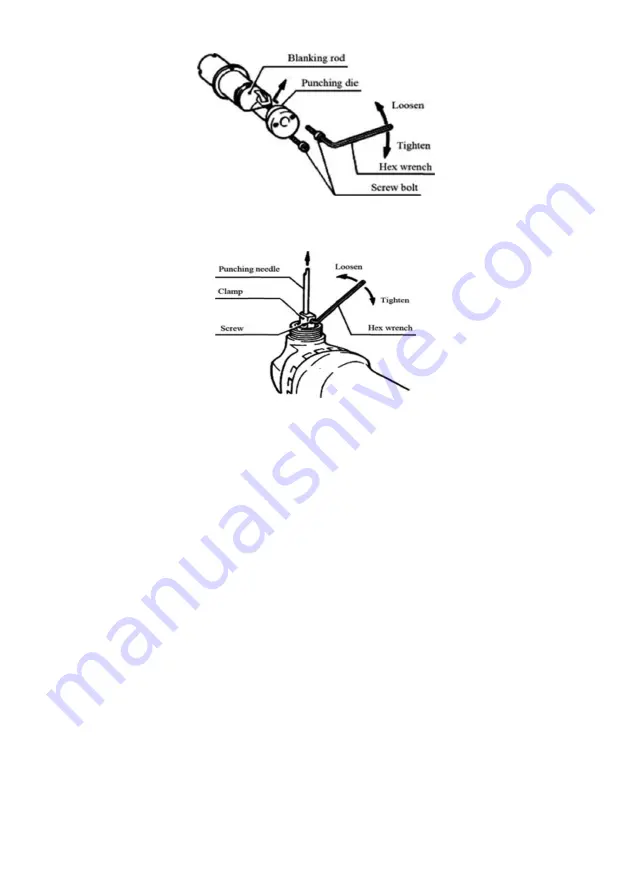

Fig 9

Fig 10

■ Assembly

♦

Installing and removing the punch and die ACaution:

Always be sure that the tool is switched off and unplugged before removing or

installing the punch and die.

1. Make sure to replace the punching needle and the punching die set. When

disassembling them, loosen the cap nut with the wrench, disassemble the rod

out of the tool, and then loosen the nut fastening the punching die with a hex

wrench. Disassemble the punching die out of the rod, and then loosen the

screw rod fastening the punching needle with a hex wrench. Pull the punching

needle out of the rod.(Fig9&Fig10)

When assembling the punching needle and the punching die, insert the

punching needle into the clamp to make the hole face the fastening screw rod

and then tighten it. Put the punching die into the blanking rod and tighten the

fix screw cap. Finally, put the blanking rod into the tool to make the punching

needle insert the tool through the hole in it and tighten the screw cap to fix