43

M-43-25

LUF-Series Lufran Manual

Revision - Date 03-01-04-18 Standard outlet, Standard Interface

Maintenance:

The LUF-series Lufran fluoropolymer inline water heater requires only a routine inspection every 6

months to check the operation of the various operation and safety devices. The maintenance procedures

listed here should only be performed by qualified technicians. Many of these devices require the control

system to remain operational during inspection, while others may be checked while the unit is completely

powered down.

Note:

Several maintenance tasks can be completed simultaneously while the cabinet access covers

are open and lockout/tagout procedures are in place.

Maintenance Schedule:

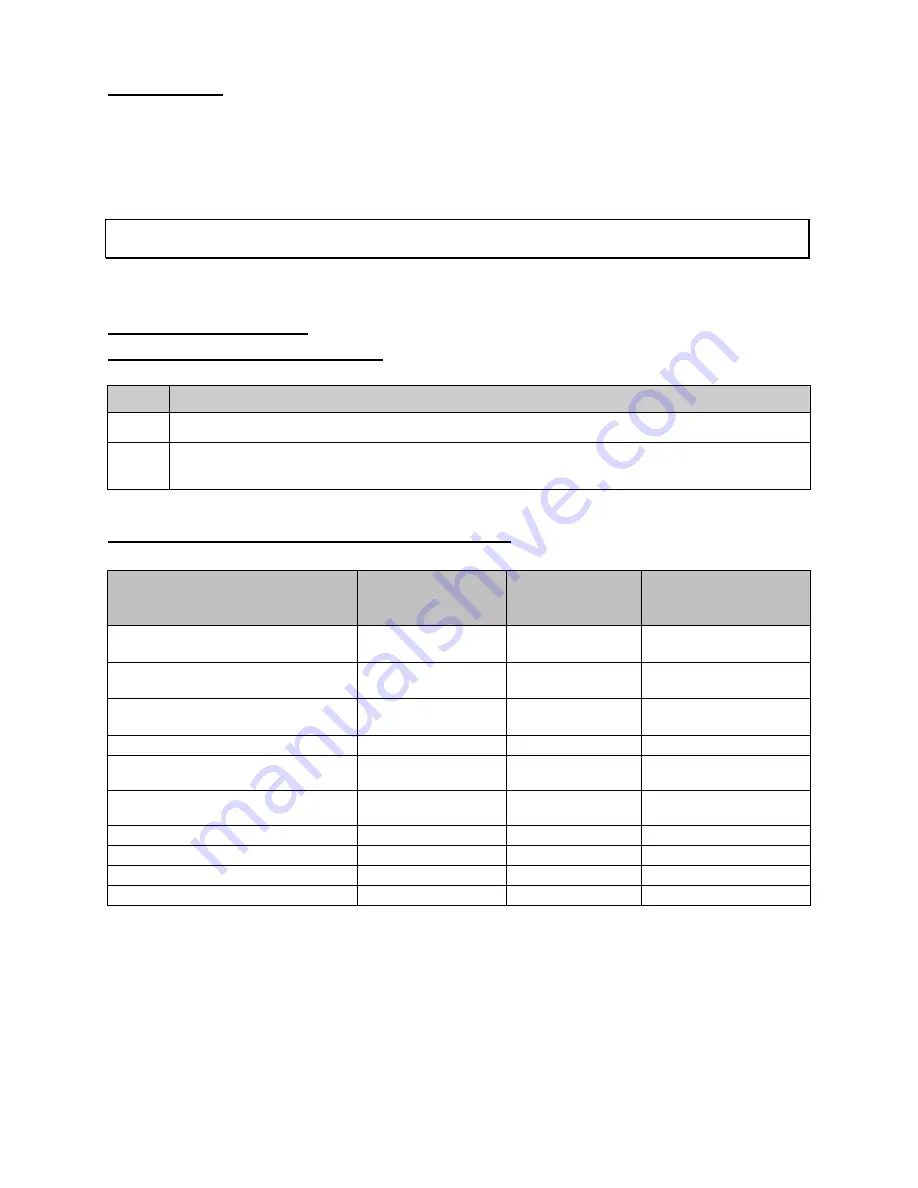

Categories of Electrical Hazards

Type

Description

1

Equipment is energized, but live circuits are covered or insulated to prevent accidental shock.

2

Equipment is energized and energized circuits of less than 24 VDC, 240 VA and 20 joules are

exposed to accidental contact.

Maintenance To Be Performed Every 6 Months:

Item to Inspect

Lockout / Tagout

Required (Y/N)

Electrical Hazard

Category (1-2)

Procedure Number

Outlet plumbing liquid level sensor,

top-half plumbing

N

1

M1

Outlet process sensor, column TC

sensor

N

1

M2

Leak detector (Optional)

N

1

M3

Purge gas flow switch

N

2

M4

Humidistat purge exhaust, humidistat

switch

N

2

M5

Pressure relief valve (PRV), bottom-

half plumbing

N

1

M6

Cabinet cooling fans

N

1

M7

SSR heat sink cooling fans

N

1

M8

Circuit breaker

N

2

M9

Safety Contactor

Y

2

M10

Summary of Contents for Lufran LUF Series

Page 63: ......