14

© 2014 Proceq SA

Single-Line Mode

PM-630

PM-650

NOTE! It is advisable to locate the first and second layer re-

bars with the Locating Mode to find the optimum line posi-

tion prior to measuring with the Single-Line Mode.

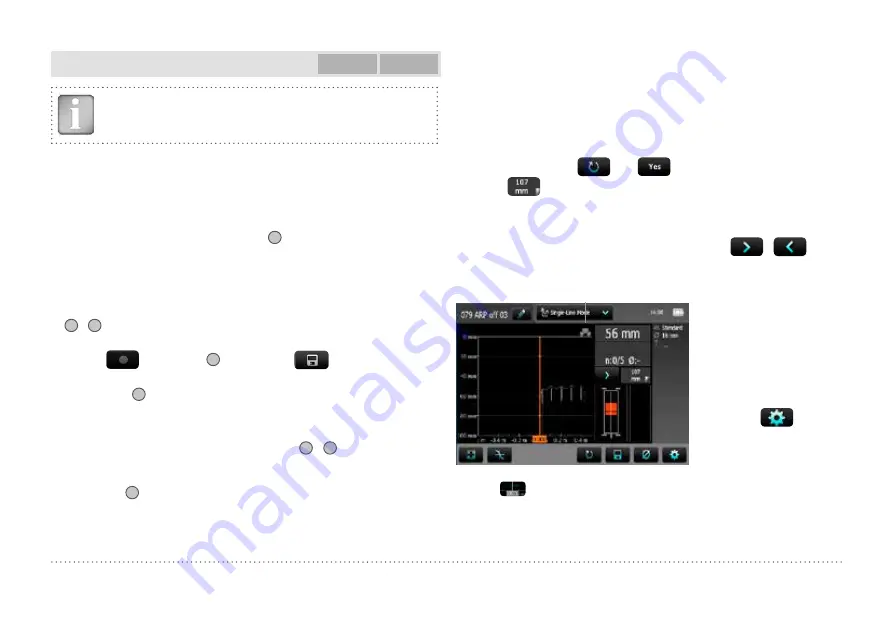

The Single-Line Mode is mainly used if cover must be shown along one

line on a rather long distance (e. g. in a tunnel). Therefore the measure-

ments are made across the first layer rebars.

The maximum scan length is 999 m / 3’280 feet in each direction (to the

right and to the left from the zero line).

• Enter the setting menu by tapping on

5

. Set the correct settings, es-

pecially Rebar Diameter, Unit, Minimum Cover and Display Curve.

In case Single-Line scanning is done over rebars of different diameters

and/or of different spacing measure each diameter.

• Position the probe cart at the start line in an optimum position (the MC

14

/

15

at the mid line of the rebars running parallel to the moving direc-

tion, both rectangles in the probe symbol are of equal minimum size).

• In case

is shown at

7

tap on it and

will be shown.

• Start with the measurement if the cursor is at the start line. If not per-

form a reset

8

.

• Move the probe cart with constant speed crosswise over the rebars,

not exceeding the maximum speed (speed bar half filled in green).

• Above each rebar, when the red LED of MC

14

/

15

lights up, you may

measure the rebar diameter and on completion, it will be displayed

in blue. The measured diameter may be deleted within 5 seconds by

tapping on

6

.

• In case the spacing between the rebars is in the range of 5 to 13 cm

(2.00 to 5.20 inch), set the respective Neighboring Rebar Correction

value first (see Figure 26).

The cursor position can be adapted in two ways to changed cart position:

• Tap on the cursor and wait until it becomes white and orange. Move

the cursor to the desired position (even left to the zero line is pos-

sible). Be aware: Scanning is not anymore possible between the new

cursor position and the zero-line. Already scanned rebars cannot be

removed by a new scanning but you may scan again on the left of

the first rebar or on the right of the last rebar. To delete the already

scanned rebars tap

and

.

• Tap on

and set the required displacement distance. In case you

must jump due to an obstacle like a column, move the cart until the

right wheels touch the column, set the displacement distance (column

width + 107 mm / 4.20 inch for the cart width) and reposition the cart

with the left wheels touching the column. Tap on

/

.

At the end when stopped scanning a marker (dotted blue line) is set.

Probe

position

Red indicates rebars with insuf-

ficient cover, others with sufficient

cover.

Red dotted is the minimum

required cover. Blue number

indicates measured diameter.

Either the Cover, Signal Strength

or None curve can be displayed

by tapping on

and chang-

ing “Display Curve”.

To see the actual cursor position short tap on the cursor and the position is shown in white on

the X-axis.

The actual position is shown in a resolution of ± 3 mm / 0.12 inch.

The rebars are displayed to scale depending on the diameter

The cover curve is shown (if selected) within the cover ranges indicated in Figure 2 but a rebar

will only be shown up to 90 % of those limits.