AP360/362 Label Applicator 13

A. Apply the Label

1. Power on the Label Applicator using the Power Switch. This can be done at any point with or

without the container in place.

2. Place the container on the rollers using the instructions in Section 3.

Important Note:

For label stock 6” and wider, it may be necessary to reduce the speed of the Label

Applicator. The AP360e/362e includes a half-speed mode that generates more power from the motors for

wider label stock. To activate this mode, hold down the Foot Switch while switching on the unit. The

AP360e/362e will revert back to the default mode when switched on without holding down the Foot

Switch.

3. Press the Foot Switch to apply the label.

4. Remove the container. The rollers will continue to spin the container for fifteen minutes after

each application. If you need to make an adjustment, do so now.

5. While the rollers are still spinning, place the next container on the rollers and press the Foot Switch.

6. Continue this process until all containers are labeled.

B. Apply two labels to the same container (AP362e only)

The AP362e has the ability to apply two labels to the same container. Using the control panel you

may also adjust the distance between the two labels. Nine different distances can be saved in the

unit’s memory. These distances are represented by nine different memory locations: F1 - F9.

(F-0 represents the single label application mode.) By choosing the desired memory location/

distance you can easily switch between multiple two-label containers without having to readjust

label distances.

Follow this procedure to apply two labels to each container:

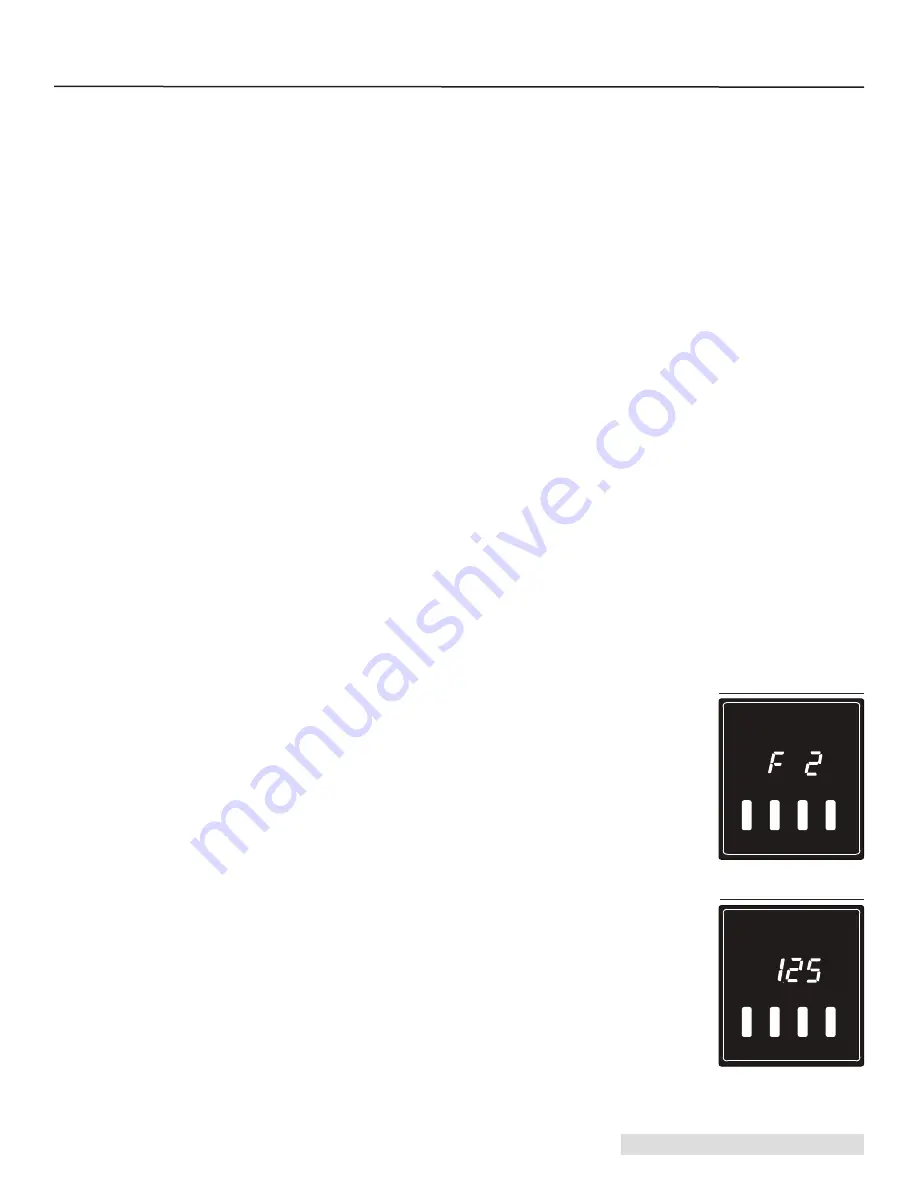

1. Press the Mode Button once to display the current memory location.

2. While in the memory mode, press the Recall/Reset button repeatedly

to move to the desired memory location (F1 - F9). (Press Recall/

Reset repeatedly to move back to F0 for single-label mode.)

(Figure 4-1.)

3. The desired memory location (F1 - F9) will be displayed for 2 seconds,

followed by the current value set for that memory location for

another 8 seconds. During this time, press the + or - button to adjust

the distance value to be set for this memory location. (Figure 4-2.)

Hold down the button to move more quickly through the values.

Once the value is set it will be displayed for 8 seconds and then

stored in memory. The screen will then revert to label counter mode.

The value displayed corresponds to inches. The unit accepts values

between 0.01 and 9.99 inches (0.25 mm to 253.7 mm).

For metric versions of the AP362e the value displayed corresponds

to centimeters. The unit accepts values between 00.1 cm (1 mm)

and 25.4 cm.

Section 4: Applying the Label

Mode

Recall/

Reset

+

-

Mode

Recall/

Reset

+

-

Figure 4-1.

Figure 4-2.