16

PM-1440BV v3 2020-10

Copyright © 2020 Quality Machine Tools, LLC

of the bed ways at the join (a visible parting line may be ac

-

ceptable, but a discontinuity that snags the saddle is not). If a

satisfactory join cannot be achieved, it may be necessary to

remove and reinstall the insert from scratch.

Figure 3-19

Gap insert

Representative

insert

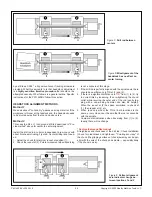

COOLANT SYSTEM

The coolant system is typically used with water-miscible

(emulsified) cutting fluid. It can also be used with lightweight

neat cutting oil straight from the can. Synthetic cutting fluids

are not recommended due to their potential for corrosion and

other undesirable effects on the lathe and the coolant pump.

If you use water-miscible cutting fluid, bear in mind that the

ratio of product to water is important — too much water causes

excessive corrosion and other problems. Check the mix from

time to time using a refractometer. If this is not available, make

up a small batch according to the product directions, then re-

place with a fresh batch when the old one becomes unusable

due to reduced performance, oil/water separation, or bad odor.

Disposal of used cutting fluid can be a problem. It is about 95%

water, so its volume can be drastically reduced by evaporation

in an open tank. The residue may then be handled like any

other waste oil.

Figure 3-20

Coolant pump assembly, RH stand cabinet