15

PM-1440BV v3 2020-10

Copyright © 2020 Quality Machine Tools, LLC

Figure 3-16

Saddle and compound lock screws

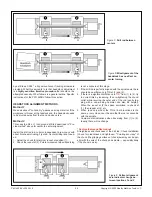

STEADY & FOLLOWER RESTS

The hinge-type steady rest, Figure 3-17, can be mounted any-

where along the lathe bed. It makes possible cutting opera-

tions on long, slender workpieces between centers, or held at

one end by chuck. The steady rest is often used in combina-

tion with the saddle-mounted follower rest, Figure 3-18.

To set the fingers on the workpiece, first swing open the upper

casting. Make certain that all three fingers are freely adjustable

by thumbwheel. If not, loosen and re-lock the set screws (ar

-

rowed). Raise the two lower fingers to just touch the workpiece

— not deflecting it — then close and secure the upper casting.

Lower the top finger to just touch the workpiece, clamp the

frame, then apply oil at the point of contact.

The follower rest, Figure 3-18, is secured to the saddle with

two 8 mm socket head screws. Adjust the follower fingers as

described for the steady rest.

Figure 3-17

Steady rest

(representative)

Figure 3-18

Follower rest

(representative)

GAP BED

An 8-3/16 in. long section of the bed at the headstock end

can be removed to allow turning of diameters up to 18-3/4 in.,

Figure 3-19.

To remove the gap insert back out the pusher screw one or

two turns, then remove the four large socket head screws se-

curing the insert to the bed. To minimize cosmetic damage, cut

through the paint and filler along the joint between insert and

bed using a sharp knife or pointed scraper.

Jack out the two taper pins using a 13 mm hex wrench.

Before re-installing the insert, be certain that all mating surfac-

es are scrupulously clean. Set the insert in place, lightly tap in

the two locating pins, then install the four large bolts (snug, but

not fully tightened). Jack the insert to the right with the pusher

screws to close the gap, if any, between the ground surfaces