7

PM-236 v4 -207.indd

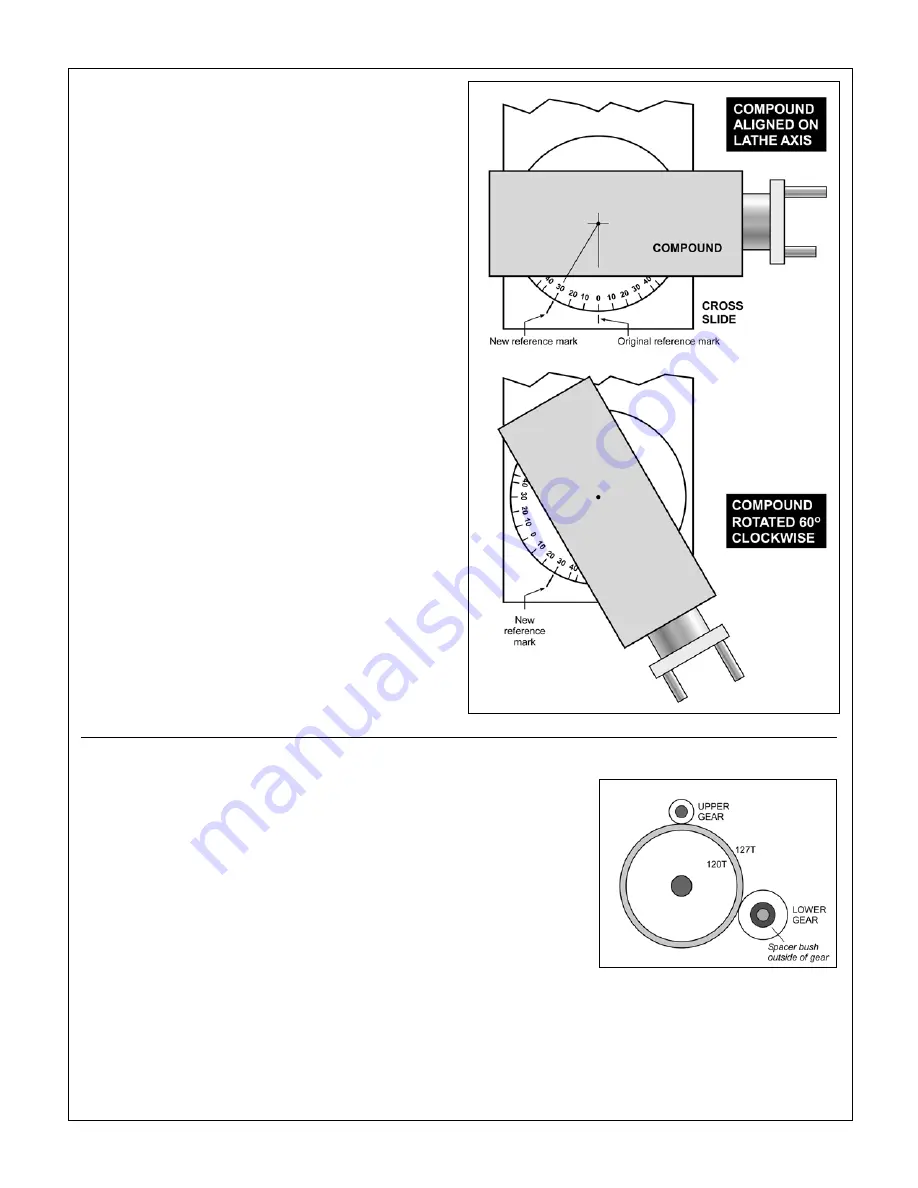

COMPOUND SETUP FOR THREAD CUTTING

Thread cutting on the lathe is unlike most other turning

operations, for two reasons: . The cutting tool must be

precisely ground with an included angle of 60 degrees

for most American and metric threads, and; 2. It is pref-

erable to feed the tool into the workpiece at an angle so

it cuts mostly on the left flank of the thread. The correct

angle relative to the cross slide (zero degrees) is a sub-

ject of debate — should it be 29, 29-/2 or 30 degrees?

Many machinists prefer 29 degrees because it holds

the cutting tool marginally clear of the right flank of the

thread, close enough for cleanup of the flank while at the

same time avoiding appreciable rubbing.

The 45

o

- 0

o

- 45

o

scale on the compound is not directly

helpful in setting the thread cutting angle, but it can be

used for that purpose if a second reference mark is ap-

plied to the cross slide. First make certain that the com-

pound is truly aligned with the lathe axis when 0

o

on the

scale is on the cross slide reference mark — do this by

indicating against a ground bar between centers while

advancing the indicator using only the compound. Allow

for the variance, if any, when applying the new reference

mark. Grind a chisel edge on a /4 in. square HS tool bit,

align it precisely on the left hand 30

o

scale mark; then,

wearing safety glasses, rap the tool bit sharply with a

hammer.

Figure 3-7

Setting up the compound for 30

o

infeed

A new reference mark is stamped on the cross slide at 30 de-

grees. To set the compound for thread cutting, rotate it clock-

wise to bring the right hand 30

o

scale mark in line with the new

reference mark. For 29

o

rotate the compound 1 degree more.

CHANGE GEARS FOR THREAD CUTTING

The large gears in Figure 3-2 are

transposing gears

,

20T and 27T. They allow a standard-thread leadscrew,

in this case 8 tpi, to cut metric threads. The transposing

gears are keyed together.

Key facts to remember

:

For U.S. thread cutting, the 27T larger gear is simply

an

idler

, transferring the drive from the upper gear to the

lower gear. In this configuration, the spacer bushing is

outside

the lower gear, as Figure 3-2.

For metric thread cutting, the lower gear is driven by the

20T transposing gear. In this configuration, not shown,

the spacer bushing is

inside

the lower gear.

Any change to the drive train typically calls for one or

both of the upper and lower gears to be exchanged for

For all TPI standard

threads (U.S.A.) the

127T gear is an idler

between upper and

lower gears.

by a larger or smaller gear. This will require the trans-

posing gear pair to be repositioned. The procedure for

this is:

Remove the M6 socket head screws from the upper

•

Figure 3-8

Standard TPI setup