cover plug from the outlet flue length and insert a CO

2

measuring instrument.

2. Turn "ON" the main electricity supply and check that the

following sequence of events occur.

i) Burner fan runs.

ii) Ignition spark is heard

iii) Main gas valves open

iv) Main gas flame is established.

3. Check that the main burner gas pressure agrees with that

in Tables 3.1 or 3.2. If necessary adjust the main burner

gas pressure

(Fig 2a - 3 or Fig 2b - 2).

4. Measure the CO

2

content of the flue gases. If necessary

adjust the combustion air damper of the burner

(Refer to

the

Burner Supplement)

to obtain a reading of 9.0 - 9.5%.

5. Turn "OFF" the main electricity supply, remove pressure

gauge and refit sealing screw in pressure test point and

flue sample point cover plug.

6.5

Final Soundness Test

1. After making final gas rate checks all joints on the gas

controls assenbly must be tested for soundness using leak

detection fluid.

6.6

Flame Safeguard

1. Whilst the burner is in operation close the gas service

valve. The burner should go to lockout within 1 second.

6.7

Handing over the Air Heater

Hand the Users Instructions to the user or purchaser for

retention and instruct in the efficient and safe operation of

the air heater and associated controls.

Adjust the automatic controls to those values required by

the User.

Finally, advise the user or purchaser that, for continued

efficient and safe operation of the air heater, it is important

that servicing is carried out annually.

In the event that the premises are not yet occupied turn off

the gas and electricity supplies and leave instructional

literature adjacent to gas meter.

7.

Servicing

WARNING:

Always switch off and disconnect electricity

supply and close the gas service valve before carrying out

any servicing work or replacement of failed components.

7.1

General

Full maintenance should be undertaken not less than once

per year. After any servicing work has been complete or any

component replaced the air heater(s) must be fully

commissioned and tested for soundness as described in

Section 6.

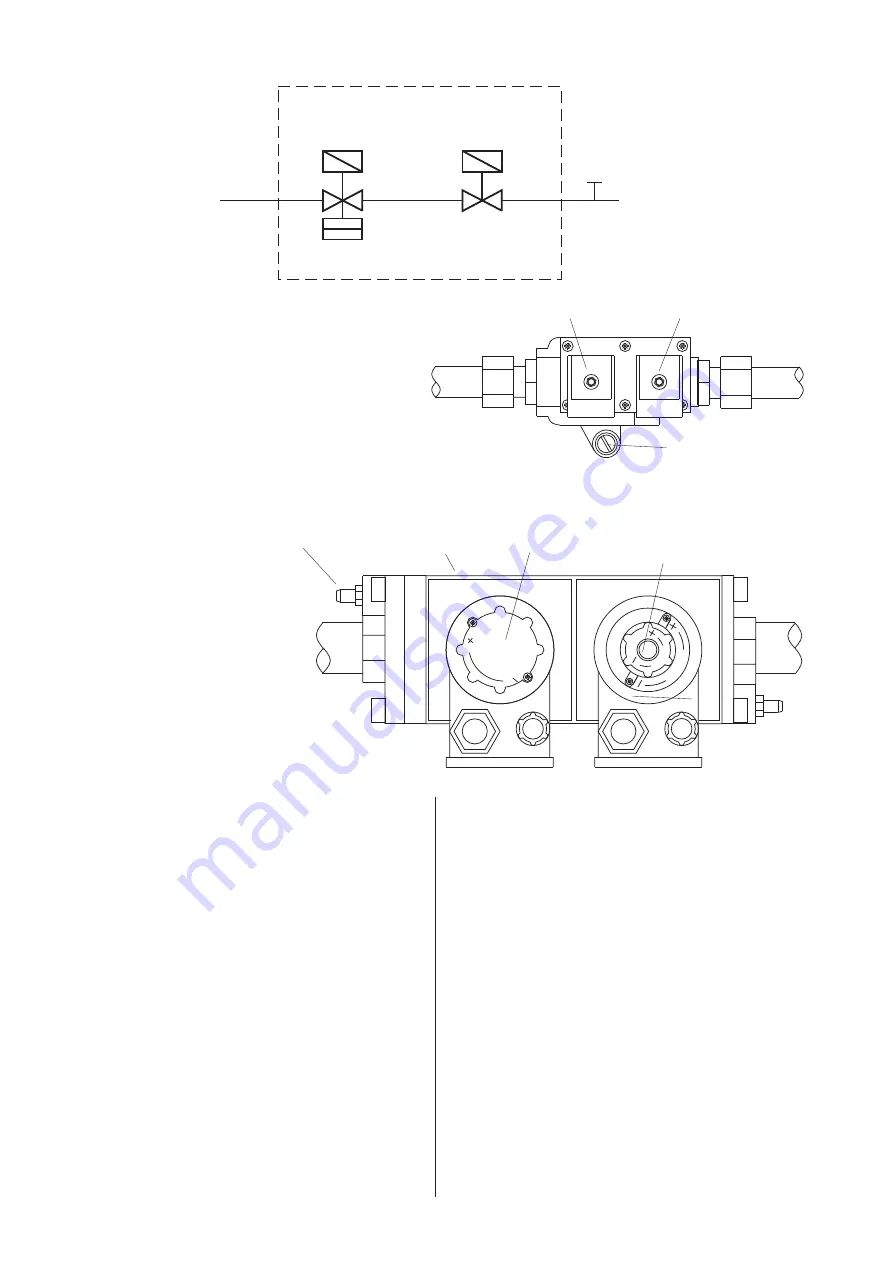

Fig 1 Gas Controls Schematics

1st Main Gas

Safety Shut-off

Valve

2nd Main Gas

Safety Shut-off

Valve

Main Gas

Governor

Gas

Inlet

To Burner

Pressure

Test

Point

Fig 2a Gas Controls Layout NCA-G 100, 150

1) 1st Main gas safety shut off valve.

2) 2nd Main gas safety shut off valve.

3) Main burner pressure adjustment screw.

Notes:-

i) Electrical connection plugs not shown.

Fig 2b Gas Controls Layout NCA-G 200, 300

1) M a i n g a s s a f e t y s h u t - o f f

valves.

2) M a i n b u r n e r p r e s s u r e

adjustment screw.

3) Inlet Pressure test point.

4) F l o w r a t e a n d v a l v e o p e n i n g

speed adjustments.

V

S

T

A

R

T

V

M

A

X

RE

G.

SE

TPO

IN

T

Gas

Inlet

To

Burner

1

2

3

4

3

6

1

2

3

Gas

Inlet

To

Burner