CPx Gas or Oil Cabinet Heater Range Issue 2.1 June 2014 Page 21

Electrical Connections

Wiring external to the air heater must be installed in accor-

dance with the I.E.E. Regulations for Electrical Installations

and any local regulations which apply. Wiring should be

completed in flexible conduit.

Heaters are for use with 230V, 1N, 50Hz or 400V, 3N, 50Hz

supplies (see heater data plate).

The method of connection to the main electricity supply

must:-

- facilitate the complete electrical isolation of the heater(s)

that will prevent remote activation of the heater during

servicing.

- be in a readily accessible position adjacent to the heater(s).

- serve only the heater(s).

- have a contact separation of at least 3mm in all poles. See

the wiring diagram for the heater electrical connections.

All units are fully prewired and only require final connections

for the incoming mains supply. Heaters not supplied with

inbuilt time and temperature controls will also require

completion of the external control circuit (230V) via a room

thermostat, time clock etc. and, if applicable, the remote low

level lockout reset.

All heaters must be earthed.

Reference must be made to Table 3 Page 21 to ascertain the

electrical loading of the unit(s) being installed so that cables

of adequate cross-sectional area are used for the electrical

installation. The length of the conductors between the cord

anchorage and the terminals must be such that the current

carrying conductors become taut before the earth conductor

if the cable or cord slips out of the cord anchorage. All exter-

nal controls must be of an approved type.

Heaters supplied less main fan must be electrically

interlocked to the air movement system so that this is started

in the same manner as the air heater fan would be viz. A

connection from the appropriate heater terminal (see wiring

diagram with the heater) must be made to one side of the fan

motor contactor coil, the other side of the coil being connect-

ed to Neutral. Under no circumstances must the fan motor

electrical supply be taken direct from the internal wiring of

the heater.

A =

2 core and earth (Single Phase)

4 core and earth (Three Phase)

B = Powrtrol = 4 core and earth

Powrtrol RR = 4 core and earth

MC200 =

4 core and earth

C =

2 core screened (MC200 model only)*

*(screen must be grounded only

at the MC200)

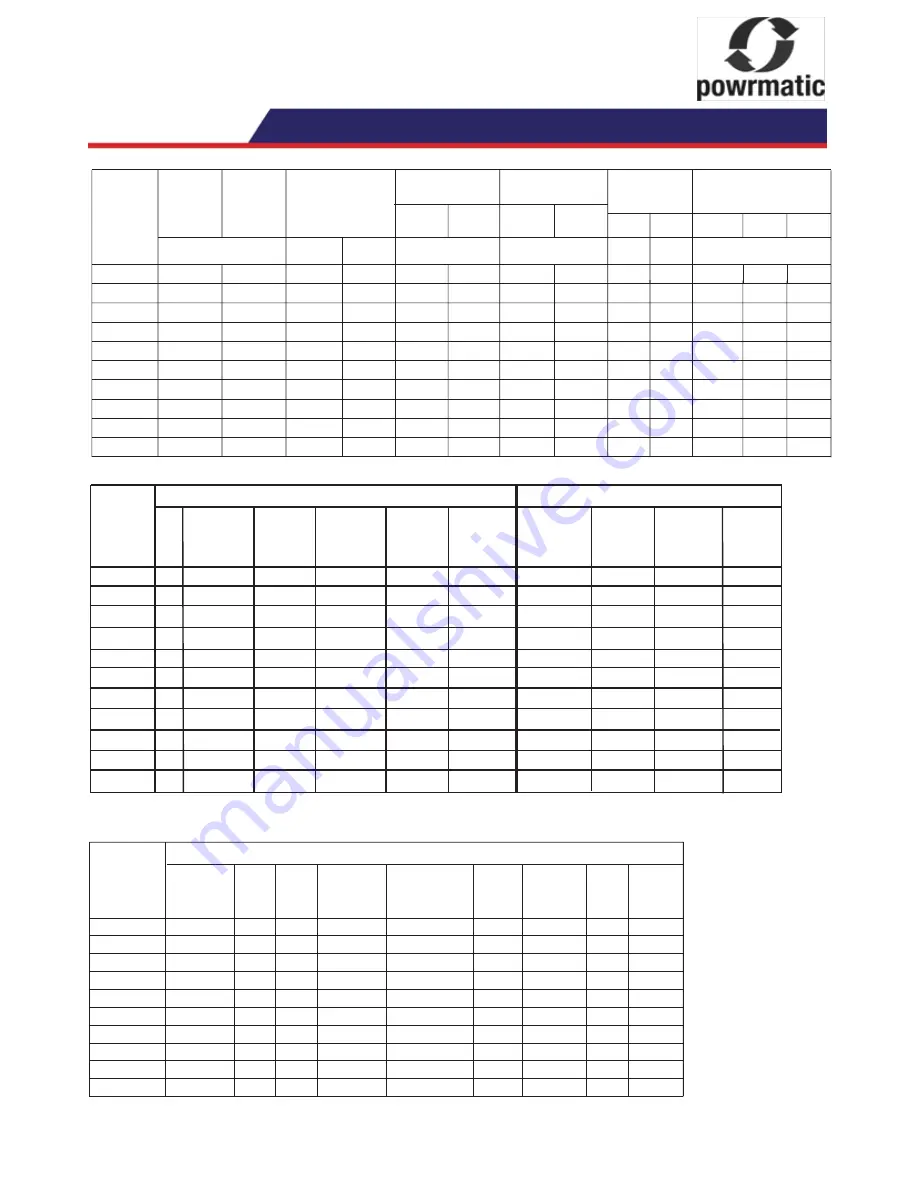

3.1 Technical Data

Table 2. Specifications

Fan motor

Gas

Oil

Model

Nom.

Input

(Nett)

Air

Volume

Standard

Motor

Uprated

Motor

Output

Maximum duct

resistant

Standard

Motor

Uprated

Motor

Kw

m³/s

pa

Kw

Weight

Fuel

Connection

Size

Kg

CPx

CPx

/NCA

CPx

/EA

CPx120

R

c

¾

341

130.4

120.0

2.3040

140

N/A

2.2

N/A

¼”

BSP

448

458

CPx300

315.2

R

c

1¼

556

290.0

5.7600

150

250

5.5

7.5

3

/

8

”

BSP

TBA TBA

CPx60

65.2

60.0

1.1520

185

N/A

0.550

N/A

R

c

¾

173

¼”

BSP

210

215

231

210

215

CPx90

90.0

97.8

1.7280

100

N/A

1.1

N/A

R

c

¾

241

¼”

BSP

304

304

CPx150

163.0

150.0

2.8800

175

240

2.2

3.3

R

c

1¼

386

¼”

BSP

535

546

CPx175

190.2

175.0

3.3600

190

250

3.3

5.5

R

c

1¼

530

¼”

BSP

TBA TBA

CPx200

217.4

200.0

3.8400

100

200

4.0

5.5

R

c

1¼

530

¼”

BSP

TBA TBA

CPx250

271.7

250.0

4.8000

N/A

150

4.0

5.5

R

c

1¼

556

3

/

8

”

BSP

TBA TBA

CPx30

194

188

32.61

30.0

R

c

½

0.5760

N/A

0.373

N/A

168

¼”

BSP

R

c

½ ¼”

BSP

206

CPx45

48.9

45.0

0.8640

m³/h

8294

20736

4147

6221

10368

12096

13824

17280

2074

3110

322

N/A

0.550

N/A

Table 3. Electrical Data

Table 4.1

Burner Pressures - Natural Gas - Group H - G20 - Net CV (H

i

) = 34.02MJ/m³

Riello Burners

Air Gas Start Gas Main Burner

Nom. Nett

Model

Type Head Gate Pressure Pressure

Input Gas Rate CO

2

Flue T.

No

No

mbar

mbar

kW

m³/h

% °C

CPxG 30

GS 5

0

N/A

N/A

4.5

32.3

3.42

9.1

145

CPxG 45

GS 10

FF

N/A

N/A

4.0

49.0

5.18

8.8

160

CPxG 60

GS 10

1

N/A

N/A

3.8

64.6

6.84

8.9

143

CPxG 90

GS 10

FF

N/A

N/A

5.3

98.3

10.40

9.0

170

CPxG 120

GS 20

2

N/A

2.7

4.5

127.4 13.48

8.9

156

CPxG 150

GS 20

FF

N/A

3.2

5.7

162.9 17.24

9.2

163

CPxG 175

GS 20

FF

N/A

2.9

5.8

190.1

20.11

8.8 157

CPxG 200

GAS 3

4

4

2.9

7.1

215.9

22.84

9.0 148

CPxG 250

GAS 3

FF

7

3.7

8.5

269.9

28.56

9.3 153

CPxG 300

GAS 3

FF

7

4.5

10.2

316.2

31.79

9.5 175

Notes:

CO

2

values and Nett flue gas temperatures are given for guidance and measured values will depend on site conditions.

FF = Fully Forward

Minimum

Inlet pressure

17.5mbar

WARNING:

Always switch off and disconnect

electricity supply, close the gas service valve or

turn off the oil supply before carrying out any

servicing work or replacement of failed compo-

nents.

4.1.1 General

Full maintenance should be undertaken not less than

once per year. After any servicing work has been com-

plete or any component replaced the air heater(s) must

be fully commissioned and tested for fuel tightness as

described in Section 2.5. Page 17

4.1.2 Burner Servicing/Maintenance

1. Refer to the burner instructions supplied with the

heater and complete the servicing/maintenance instruc-

tions therein. Note: In the case of gas burners ignore any

references in the burner supplement to the gas controls

assembly.

4.1.3 Heat Exchanger Cleaning

1. Removing the upper rear panel of the heater exposes

the heat exchanger rear clean out panel.

2. Removing the fan/limit thermostat(s) as described in

4.1.6.6.4, Page 25 disconnecting the flue and then

removing the upper front panel of the heater exposes the

heat exchanger front clean out panels. If the flue cannot

be disconnected removal of the side panels exposes the

upper front header side clean out plates.

3. Remove the nuts securing the clean out panel(s) as

appropriate and remove panel(s).

4. If heat exchanger baffles are fitted, withdraw them.

5. Brush through heat exchanger tubes and remove loose

material using a vacuum cleaner.

6. If it is necessary to also gain access to the combustion

chamber disconnect the fuel and electrical connections

from the burner. Remove the nuts securing the burner to

the heater and withdraw the burner from the burner tube.

7. Reassemble all components in reverse order. Note:

Replace any gaskets with new ones.

4.1.4 Fan Assembly

1. Remove the lower panels of the heater to gain access

to the fan section.

2. Inspect the fan blades to see that they are not dam-

aged and that there is no excessive build up of deposits

that could give rise to an imbalance. If necessary clean

the fan blades using a stiff brush and vacuum cleaner.

3. Replace panels accordingly.

4.1.5 Oil Filter (if applicable)

1. Release the securing bolt, or unscrew the filter bowl, to

access the filter.

2. Clean the filter or replace as deemed necessary.

3. Refit bowl ensuring that seals are correctly in place.

4.1.6 Replacement of Faulty

Components

4.1.6.1 Burner Components

1. Refer to the burner instructions supplied with the heater

for information regarding replacement of components

within the burner.

4.1.6.2 Gas Controls Assembly (if

applicable)

1. Remove the electrical connections from the gas control

block.

2. Release the nuts securing the inlet and outlet flanges to

the gas control block and lift out the gas control block. Fit

the replacement assembly in reverse order ensuring the

valve is correctly orientated =for the direction of gas flow.

4.1.6.3 Main Air Fan and Motor

Important: On 3ph heaters fitted with 3ph main

fan motors ensure that the fan direction of

rotation corresponds with the direction of rotation

arrow on the fan guard or case. If necessary

reverse the direction of rotation by interchanging

any two of the motor live leads at the terminal

strip in the electrical panel. Should it be neces-

sary to remove one or more of the fans for clean-

ing proceed as follows.

4.1.6.3.1 CPx 30 - CPx 120

Note: These heaters are fitted with direct drive

fan units.

1. Disconnect the fan motor electrical leads from

the terminal strip (Refer to wiring diagram

supplied with the heater)

2. Remove the two screws, one on each side of

the fan mounting flange, that secure the fan to the

fan shroud.

3. Remove the screws securing the heat

exchanger mounting frame to the fan shroud on

the side that the fan is going to be withdrawn.

4. Withdraw the fan from the slide rails.

5. Reassemble in reverse order.

4.1.6.3.2 CPx 150 - CPx 300

Note: These units are fitted with belt driven main

air fans.

1.Remove the lower side panel(s).

2. Release the motor mounting plate securing

screws and then remove the belt tension by

turning the tension adjustment screw anticlock

wise. Remove the fan belts.

3. Remove the screws securing the fan mounting

feet to the heater framework and remove the fan.

It may be necessary to re-orientate the fan within

the fan compartment and also to release the fan

shroud fixings in order to pass the fan through

the heater frame. On units with twin or triple fan

sets on a common fan shaft it will be necessary to

first remove the fan shaft.

4. Inspect the fan belts and if necessary replace

with new.

5. Replace components in reverse order.

6. Do not over tension the fan belts. There should

be approximately 15mm of deflection when

downward pressure is applied to the belt(s)

halfway between the motor and fan pulleys.

Fig 3 Fan belt tension setting

4.1.6.6.4 Fan / Limit Thermostat Hon-

eywell L4064B

NOTE:

Larger heaters have two fan and limit

thermostats fitted.

Either one will start the main fans and either one

will shut down the burner in the event of an over-

heat situation.

1. Squeeze the sides of the cover and remove

cover by pulling forward.

2. Release wiring from clamp terminals by push-

ing a small screwdriver into the clamp release

holes adjacent to the clamps.

3. Remove the 2 screws securing the thermostat

to the heater panel and withdraw thermostat.

4. Reassemble new unit in reverse order referring

to the heater wiring diagram to ensure correct

wiring location.

Important:

A replacement fan/limit thermostat

may have a brass link between the bottom fan

terminal and the bottom limit terminal (situated in

the slot between the two terminals). This

MUST

be removed, by breaking the link off using a pair

of thin nose pliers, before the replacement

thermostat is installed.

Standard Motor

Uprated Motor

Fitted to EA models as standard

Nominal Plate Start

Run

Fuse Nominal Start Run Fuse

Model ph Motor Amps Amps Amps Rating Motor Amps

Amps Amps

R.P.M.

(A) (A) (A) (A) R.P.M. (A)

(A) (A)

CPx30

1

1370 3.3 6.5 4.2 5 N/A N/A

N/A

N/A

CPx45

1

1250 5.0 9.1 5.0 7 N/A N/A

N/A

N/A

CPx60

1

930 3.1 8.1 4.7 7 N/A N/A

N/A

N/A

CPx90G

1

900 9.8 18.0 7.2 10 N/A N/A

N/A N/A

CPx90O

1

900 9.8 18.0 6.5 10 N/A N/A

N/A N/A

CPx120

3

900 5.3 13.1 4.8 7 N/A N/A

N/A N/A

CPx150 3 1500 4.91

32.5

5.1

7

1500

25.0 5.75

10

CPx175 3 1500 6.47

20.8

6.9

10

1500

35.0 11.0

15

CPx200 3 1500 8.14

38.0

6.5

10

1500

35.0 8.83

15

CPx250 3 1500 8.14

58.0

9.0

15

1500

35.0 11.65

15

CPx300 3 1500 10.9

80.0

9.7

15

1500

32.0 14.4

15