CPx Gas or Oil Cabinet Heater Range Issue 2.1 June 2014 Page 13

2.1.1 General

Before installation, check that the local distribution condi-

tions, fuel specification, and adjustment of the appliance

(see data plate) are compatible.

Important:

Copper Sulphide / ‘Black Dust’

In some areas of the UK, particularly Northern Ireland,

problems have been experienced with copper sulphide

(more commonly referred to as ‘Black Dust’) forming on

the inner surfaces of copper gas supply pipework. This

dust can enter the gas stream and may lead to blockages

of valves, filters and injectors.

If this heater is being installed in an area where ‘Black

Dust’ is known to be a problem, and copper gas supply

pipework is used, it is recommended that a filter having a

stainless steel 50 micron mesh and suitable for Natural

Gas is fitted at the inlet to the appliance immediately

downstream of the main appliance isolation valve. The

end user should be advised that the filter will require

periodic cleaning or replacement at least once per year,

during the annual service, or more often if the problem is

severe.

2.1.2 Location

The location chosen for the air heater must permit:

- the provision of a satisfactory flue system and an

adequate air supply.

- adequate space for servicing and air circulation around

the air heater.

The heater(s) must not be installed in conditions for which

it is not specifically designed e.g. where the atmosphere

is corrosive or salty, and they are not suitable for outdoor

use unless the CPx/EA style is specified. CPx/EA heaters

must be installed on a plinth such that there is a minimum

distance of 0.5m between ground level and the lowest

point of any air inlet grilles.

Where the location of the air heater is such that it might

suffer external mechanical damage e.g. from overhead

cranes, fork lift trucks, it must be suitably protected.

CPx heaters are for normal operation within an ambient

temperature range of -10 to 25°C.

The air heater must be installed in accordance with the

rules in force and the relevant requirements of any fire

regulations or insurance company's requirements apper-

taining to the area in which the heater is located, particu-

larly where special risks are involved such as areas where

petrol vehicles are housed, where cellulose spraying is

carried out, in wood working departments etc.

IMPORTANT:

Heaters shall not be installed in:-

a) Those parts of spaces within buildings that

have been classified as hazardous areas as

defined in BS EN 60079-14.

b) Where there is a foreseeable risk of flammable

particles or gases or corrosion inducing gases or

vapours being drawn into either the heated air

stream or the air for combustion. In such cases

installation may only proceed if both air sources

are from an uncontaminated source, preferably

from outside the building. It may also be neces-

sary to purge the air heater before the burner is

allowed to fire. In certain situations where only

airborne particles are present it may suffice to fit

filters on the main air inlet duct of the heater.

Advice in these instances must be obtained from

Powrmatic Ltd.

c) In areas subjected to significant negative pres-

sures due to extract systems.

2.1.3 Installing the Air Heater

If necessary consideration should be given to mounting

the heater on resilient pads, or equivalent, to minimize

transfer of noise and vibration to the structure of the build-

ing.

Floor mounted heaters must be installed on a level

noncombustible surface.

Heaters mounted at high level must be supported on a

purpose designed platform or framework that is suspend-

ed from vertical drop rods, chains or straps or mounted on

specifically designed cantilever brackets from a non-com-

bustible wall. The method of installation support must be

capable of adequately supporting the weight of the unit

(See Table 2, Page 21) and any ancillary equipment.

Before installing the heater the existing structure must be

inspected to ensure it is suitable. All supports should be

protected against the effects of rust or corrosion.

Whichever method of mounting the air heater is used the

following minimum clearances for installation and servic-

ing must be observed.

Important:

CPx 250 & CPx 300 heaters have louvred lower

panels on both sides. The minimum clearance of

0.15m is increased to 0.5m.

Important:

Smaller heaters are supplied with one blank side

panel and one louvred side panel. If the heater is

installed against a wall ensure that the blank

panel is facing the wall, interchanging the two side

panels if necessary.

Any combustible material adjacent to the air

heater and the flue system must be so placed or

shielded as to ensure that its temperature does

not exceed 65 °C.

If the method of mounting allows for any move-

ment of the heater it is essential that all gas, duct,

and electrical connections to the heater are made

with flexible connections to maintain continuity of

connection.

2.1.4 Combustion & Ventilation Air

Supply

There shall be provision for a supply of air for combustion

and, in the case of heaters installed in an enclosure or

plant room, for ventilation.

Actual values relating to the details below

1) Installation in the heated space

In buildings with a design air change rate of 0.5 /h or great-

er, additional natural or mechanical ventilation is not

necessary. In buildings not having a design air change

rate of 0.5 /h the following apply.

Natural Ventilation

Grilles having a free area of at least 2cm² per kW of rated

heat input shall be provided at low level i.e. below the level

of the heater flue connection.

Mechanical Ventilation

Must ensure that the space air change rate is at least

0.5/h, must be of the ‘input’ type and interlocked to ensure

the heaters cannot work if the input system is not working.

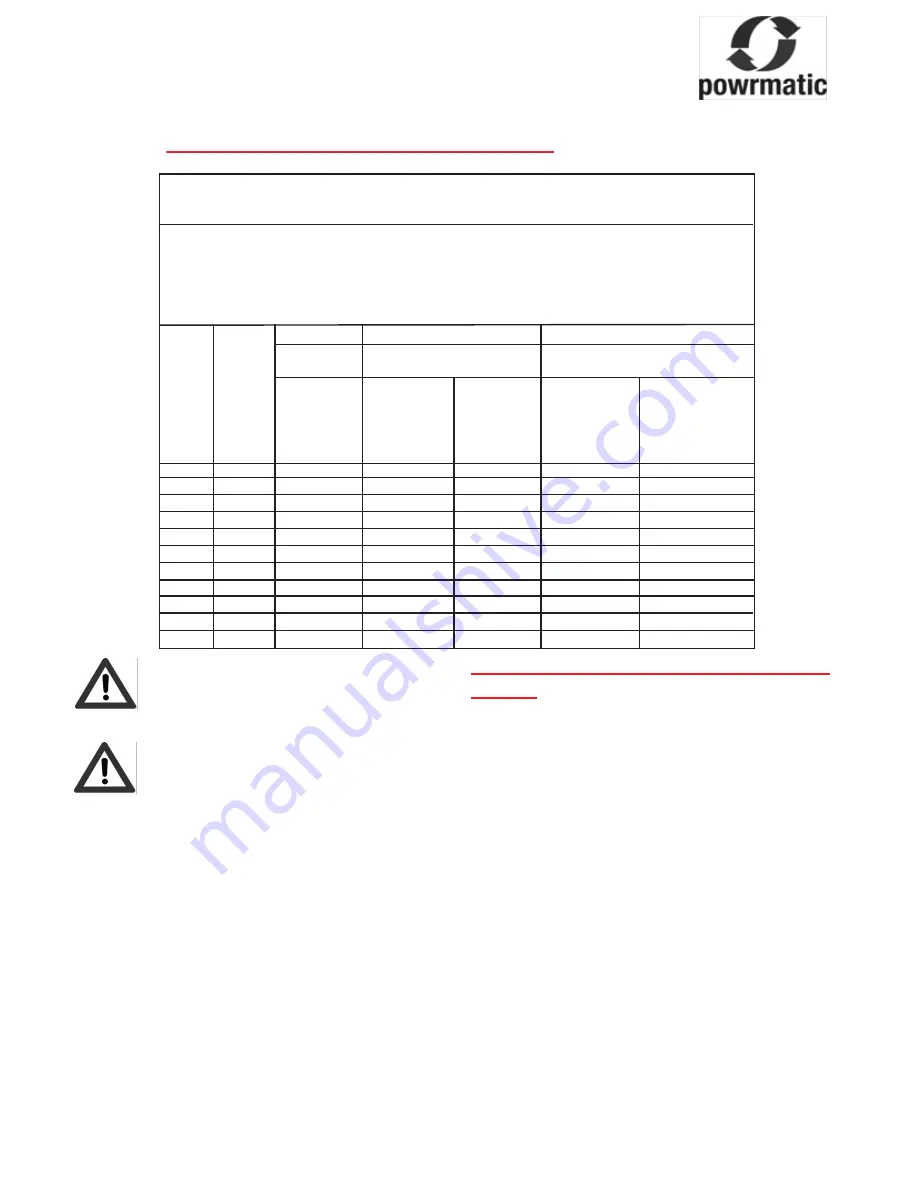

CPx Combustion & Ventilation Air Supply

Type B23 Installation

These refer to section 2.1.4. of the instructions

Air vents shall be permanently open.

Figures in column 1 are for heaters installed in the space they are heating.

Figures in column 2 are for heaters installed in a plant room, ventilation to outside air.

Figures in column 3 are for heaters installed in a enclosures, ventilation to outside air.

In all cases figures are per heater installed.

For multi heaters installations the appropriate values for each heater must be added together.

1

2

3

In the

In a plant room

In an enclosure

Space

CPx

Input

Low

Low

High

Low

High

kW

Level

Level

Level

Level

Level

Grille

Grille

Grille

Grille

Grille

Free

Free

Free

Free

Free

Area

Area

Area

Area

Area

cm

2

cm

2

cm

2

cm

2

cm

2

30

32.29

64.6

129.2

64.6

322.9

161.5

45

48.97

97.9

195.9

97.9

489.7

244.8

60

64.62

129.2

258.5

129.6

646.2

323.1

90

98.31

196.6

393.2

196.6

983.1

491.5

120

127.43

254.9

509.7

254.9

1274.3

637.1

150

162.90

325.8

651.6

325.8

1629.0

814.5

175

190.07

380.1

760.3

380.1

1900.7

950.4

200

215.87

431.7

863.5

431.7

2158.7

1079.3

250

269.86

539.7

1079.4

539.7

2698.6

1349.3

300

316.25

632.5

1265.0

632.5

3162.5

1581.2

2) Installation in plant rooms or enclosures

There must be permanent air vents communicating direct-

ly with the outside air, at high level and at low level.

Plant Rooms

Low level (inlet) 4cm²/kw of total rated net heat input

High level (outlet) 2cm²/kw of total rated net heat input

Enclosures

Low level (inlet) 10cm²/kw of total rated net heat input

High level (outlet) 5cm²/kw of total rated net heat input

Mechanical Ventilation

The minimum flow rate of ventilation shall be 4.14m³/h per

kilowatt of total rated heat input.

2.1.5. Gas Connection (if applicable)

• A servicing valve and union must be fitted at the gas inlet

to the heater to facilitate servicing.

• The gas supply to the air heater must be completed in

solid pipe work and be adequately supported.

• Heaters suspended by drop rods, straps or chains must

have a flexible connection as the final link between the

gas supply pipe work and the heater. Sufficient slack must

be left in the connection to take account of normal move-

ment of the heater.

Warning:

When completing the final gas connection to the

heater do not place undue strain on the gas pipe

work of the heater.

2.1.6. Oil Connection (if applicable)

Refer to the supplied burner installation instructions for

details regarding oil supply options.

2.1.7. Air Distribution System

For free-blowing units used in buildings having a low heat

loss i.e. where single units are required to cover a large

floor area, and in buildings with high roof or ceiling heights

Calecon thermal economiser units should be fitted to

ensure even heat distribution and minimise stratification.

Care should be taken to avoid impeding the heater air

throw with racking, partitions, plant or machinery etc.

Various outlet configurations are available as optional

extras to modify the air throw pattern to suit particular site

conditions.

CPx*/D models are designed for use with duct work to

more precisely define the point of air delivery, and /or

provide ducted return air or ducted fresh air inlet. All duct-

ing must be independently supported of the air heater.

All delivery and return air ducts, including air filters,

jointing and any insulation or lining must be constructed

entirely of materials which will not contribute to a fire, are

of adequate strength and dimensionally stable for the

maximum internal and external temperatures to which

they are to be exposed during commissioning and normal

operation.

Where inter-joist spaces are used as duct routes they

should be suitably lined with a fire-resisting material.

A full and unobstructed return air path to the air heater(s)

must be provided. If the air heater(s) is installed in a plant

room the return air intake(s) and the warm air outlet(s)

from the heater(s) must be fully ducted, into and out of the

plant room to avoid interference with the operation of the

heater from other equipment.

The openings in the structure of the plant room through

which the ducting passes must be fire stopped. Care must

be taken to ensure that return-air intakes are kept clear of

sources of smells and fumes, and where there is any

possibility of pollution of the air by dust, shavings etc.,

precautions must be taken to prevent contamination.

If necessary suitable barrier rails should be provided to

prevent any combustible material being placed within

900mm of the outlets.

Joints and seams of supply ducts and fittings must be

securely fastened and made airtight.

It is recommended that ducting should be connected to

the heater spigots via an airtight flexible coupling of

noncombustible material. Before fitting coupling it must

be ensured that an adequate clearance will be maintained

between the ends of the ducting and the heater spigots.

If required sound attenuators may be fitted in inlet and

outlet ducts to reduce airborne fan noise. Materials used

in outlet sound attenuators must be capable of withstand-

ing 100°C air temperature without any deterioration.

2.1.8 Room Thermostat Siting

If a remote room thermostat, or controller with an integral

sensor, is used it should be fitted at a point which will be

generally representative of the heated area as far as

temperature is concerned. Draughty areas, areas

subjected to direct heat e.g. from the sun, and areas

where the air movement is relatively stagnant e.g. in

recesses, are all positions to be avoided for siting the

thermostat.

The thermostat should be mounted about 1.5m (5ft) from

floor level.

Any room thermostat, frost thermostat, time clock etc.

must be suitable for switching 230V, 5A and must be of

the 'snap action' type to minimise contact bounce.

For electrical connections of external controls see the

accompanying wiring diagram.

Electrical Connections

Wiring external to the air heater must be installed in accor-

dance with the I.E.E. Regulations for Electrical Installations

and any local regulations which apply. Wiring should be

completed in flexible conduit.

Heaters are for use with 230V, 1N, 50Hz or 400V, 3N, 50Hz

supplies (see heater data plate).

The method of connection to the main electricity supply

must:-

- facilitate the complete electrical isolation of the heater(s)

that will prevent remote activation of the heater during

servicing.

- be in a readily accessible position adjacent to the heater(s).

- serve only the heater(s).

- have a contact separation of at least 3mm in all poles. See

the wiring diagram for the heater electrical connections.

All units are fully prewired and only require final connections

for the incoming mains supply. Heaters not supplied with

inbuilt time and temperature controls will also require

completion of the external control circuit (230V) via a room

thermostat, time clock etc. and, if applicable, the remote low

level lockout reset.

All heaters must be earthed.

Reference must be made to Table 3 Page 21 to ascertain the

electrical loading of the unit(s) being installed so that cables

of adequate cross-sectional area are used for the electrical

installation. The length of the conductors between the cord

anchorage and the terminals must be such that the current

carrying conductors become taut before the earth conductor

if the cable or cord slips out of the cord anchorage. All exter-

nal controls must be of an approved type.

Heaters supplied less main fan must be electrically

interlocked to the air movement system so that this is started

in the same manner as the air heater fan would be viz. A

connection from the appropriate heater terminal (see wiring

diagram with the heater) must be made to one side of the fan

motor contactor coil, the other side of the coil being connect-

ed to Neutral. Under no circumstances must the fan motor

electrical supply be taken direct from the internal wiring of

the heater.

A =

2 core and earth (Single Phase)

4 core and earth (Three Phase)

B = Powrtrol = 4 core and earth

Powrtrol RR = 4 core and earth

MC200 =

4 core and earth

C =

2 core screened (MC200 model only)*

*(screen must be grounded only

at the MC200)