MAINTENANCE

Turn the switch to the OFF position and disconnect the

machine from power source before any maintenance.

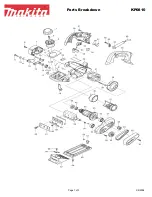

CHECK AND REPLACE THE BLADES

Refer to Figure 9 and 10

• Locate the blade cover on the back of planer. Loosen

and remove thumb screws from blade guard.

• Identify the cutterhead inside. Watch for TWO sharp

blades on the cutterhead.

• Without touching the blades, carefully turn the

cutterhead until it stops by the self-engaging latch.

• Use T Wrench to remove 6 bolts on the blade

assembly.

• Attach 2 provided magnets to the gib and carefully

remove it.

• Attach 2 provided magnets to the blades and carefully

remove it.

• Check to see if the blade is dull, worn, nicked, torn, and

uneven. These can result in poor performance such as

fuzzy grain, chipped grain, raised grain, raised edge,

and uneven cut.

• Replace with new blades in pairs only. Never mix new

blade with old blade on the cutterhead. Never mix

blades with different degrees of wear. Never use a

blade where unbalanced wear from side to side is

present.

• To replace with the new blade, use the 2 provided

magnets to transfer the blade onto the cutterhead.

Position the blade so it sits securely on the two pins.

• Use the 2 provided magnets to transfer the gib onto the

blade. Position the gib so the 6 holes are aligned with

the holes on the cutterhead.

• Tighten and secure with 6 bolts.

• To access the other blade assembly, gently pull and

hold the latch on the side of cutterhead to release it.

Once the cutterhead rotates, release the latch.

• Without touching the blades, carefully turn the

cutterhead until it stops the self-engaging latch.

• Repeat the same procedure to check and replace the

other blade.

• Replace the blade cover and secure with the two thumb

screws.

INSPECT AND REPLACE THE MOTOR

BRUSHES

• Turn the switch to the “OFF” position and disconnect the

planer machine from the power source.

• Inspect the motor brushes after every 100 hours of use.

Brush life varies, depending on the motor loads.

• Replace the motor brushes in set (two brushes) only.

Replace with new parts only.

• To inspect motor brushes, unscrew brush caps on the

sides of motor. There are two caps, one on each side of

motor.

• Remove brush assembly from motor.

• Replace motor brushes if the length of carbon has been

worn to less than 3/8”, or if the springs are worn, or if the

motor does not run smoothly.

• Replace with new motor brush assembly.

• Replace the brush cap and tighten the screw.

• Repeat the same procedure on the other side of motor.

WARNING

8

Figure 9

Figure 10

Magnets

Gib

Blade

Latch

Pin

Cutterhead

Socket Head

Screw

Summary of Contents for PL1251

Page 14: ...Figure 11 12 1 2 THICKNESS PLANER PARTS ILLUSTRATION 12 ...

Page 18: ......

Page 19: ......

Page 20: ...Southern Technologies LLC 3816 Hawthorn Court Waukegan IL 60087 ...