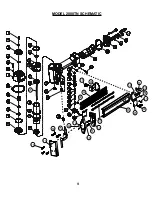

8

ITEM DESCRIPTION

Avail.

PART #

1

SCREW M4 x 10mm

n/a

2

BUSHING

n/a

3

EXHAUST COVER

n/a

4

WASHER

n/a

5

SCREW M5 x 20mm

n/a

6

SPRING WASHER 5

n/a

7

CYLINDER CAP

09-20FN2007

8

GASKET

S

09-20FN2008

8a

SPRING

09-20FN20082

9

VALVE SEAT

09-20FN2009

10

O-RING 15.7 x 2

KIT

09-20FN2010

11

O-RING 38.8 x 3

KIT

09-20FN2011

12

VALVE

09-20FN2012

13

O-RING 33.5 x 3.5

KIT

09-20FN2013

14

STOPPED WASHER

n/a

15

COLLAR

n/a

16

O-RING 50.5 x 2.5

KIT

09-20FN2016

17

O-RING 28.3 x 3

KIT

09-20FN2017

18

PISTON ASSM w/DRIVE BLD

S

09-20TN5018

19

CYLINDER

S

09-20FN2019

20

O-RING 36.3 x 2.5

KIT

09-20FN2020

21

O-RING 35.3 x 2.5

KIT

09-20FN2021

22

BUMPER

S

09-20FN2022

23

BODY

n/a

24

JOINT GUIDE

S

09-20FN2024

25

SAFE GUIDE

n/a

26

SPRING

S

09-20FN2026

27

DRIVE BLADE

n/a

See #18

28

SPRING PIN 3 x 26

n/a

29

SEAL

n/a

30

TRIGGER VALVE HEAD

n/a

31

O-RING 15 x 1.9

n/a

32

TRIGGER VALVE GUIDE

n/a

33

O-RING 5.5 x 1.5

n/a

34

SPRING

n/a

35

TRIGGER VALVE STEM

n/a

36

SPRING

n/a

37

WASHER

S

09-20FN2037

38

TRIGGER ASSEMBLY

n/a

ITEM DESCRIPTION

Avail.

PART #

39

TRIGGER PIN

n/a

40

SCREW M4 x 16mm

n/a

41

WASHER

n/a

42

.125 DIA x .312 ROLL PIN

S

09-20FN2042

43

CHANNEL

S

09-20FN2043

44

CHANNEL GUIDE

S

09-20FN2044

45

CHANNEL BRACKET

S

09-20FN2045

46

M4-0.7 x 10mm S.H.C.S. (CH

BRACKET & PLATE)

S

09-20FN2046

47

M4-0.7 x 14mm B.H.C.S. (PUSH-

ER STOP)

S

09-20FN2047

48

LOCK PLATE

S

09-20FN2048

49

M4-0.7 x 5mm S.H.C.S.

S

09-20FN2049

50

GATE

S

09-20TN5050

51

M4-0.7 x 16mm F.H.C.S.(w/patch)

S

09-20FN2051

56

NAIL PUSHER

S

09-20FN2056

57

SPRING

S

09-20FN2057

58

LOCK PIN

S

09-20FN2058

59

LOCKING WASHER

S

09-20FN2059

60

TORSION SPRING

S

09-20FN2060

61

LOCK

S

09-20FN2061

65

AIR PLUG

n/a

66

NUT M5

09-20FN2066

67

M5-0.8 x 18mm S.H.C.S. (Bracket)

S

09-20FN2067

68

SOFT GRIP SLEEVE

n/a

69

GASKET

n/a

70

END CAP

n/a

71

FOOT

S

09-20TN5071

72

GATE PLATE

S

09-20TN5072

75

SAFETY

S

09-20TN5075

78

M4-0.7 x 14mm S.H.C.S.

S

09-20FN2078

80

M5-0.8 x 20mm S.H.C.S.

S

09-20FS5080

90

Model 2000 Seal Kit

S

09-20FN2090SK

MODEL 2000TN PARTS LIST

KEY: S=Sold Separately, n/a Not available separately, KIT=Sold as part of a Kit