17

NOVA PLUS Installation & Operation Manual -

POWER FLAME INCORPORATED

DC4 DRAFT CONTROL

ENTER

ESC

®

E.

Occasional low voltage supply. Have local utility correct. Make certain that the

burner control circuit transformer (if supplied) is correct for the voltage being

supplied.

F.

Occasional low gas supply pressure. Have utility correct.

G.

Element air pressure switch opens during purge. Reset switch to remain closed

just under maximum purge pressure.

3.

Burner Motor Runs, but Pilot Does Not Light

A.

Gas supply to burner shut off – make sure all manual gas supply valves are

open. Automatic high pressure valve at meter such as Sentry type tripped shut

due to high gas pressure – reset valve and correct cause for trip out.

B.

Pilot solenoid valve not opening – listen and feel for valve actuation. Solenoid

valve not being powered – check electrical circuitry. Replace coil or entire valve

if coil is burned out.

C.

Defective gas pilot regulator – replace.

D.

Gas pressure too high or too low at pilot orifice. Check orifice size in gas pilot

assembly. Replace if incorrect. Refer to gas pilot adjustments for correct

settings. Readjust as required.

E.

Defective ignition transformer – replace. Incorrect ignition electrode settings –

refer to gas pilot adjustments for correct settings.

F.

Defective flame safeguard control or plug in purge timing card. Replace as

required.

G.

Air flow switch not making circuit – check out electrically and correct pressure

adjustment on switch, if required. Defective air flow switch – replace. Air switch

negative pressure sensing tube out of position – reposition as necessary.

4.

Burner Motor Runs and Pilot Lights, but Main Gas Flame Is Not Established

A.

Main shutoff or test cock closed. Check to make certain fully open.

B.

Pilot flame signal reading too low to pull in flame safeguard relay. Refer to gas

pilot settings section and readjust as required.

C.

Defective automatic main or auxiliary gas shut off valves. Check electrical

circuitry to valves. Replace valves or correct circuitry as required.

D.

Defective flame safeguard control or plug in amplifier. Check and replace as

required.

E.

Butterfly valve set incorrectly on modulating burner. Readjust as required.

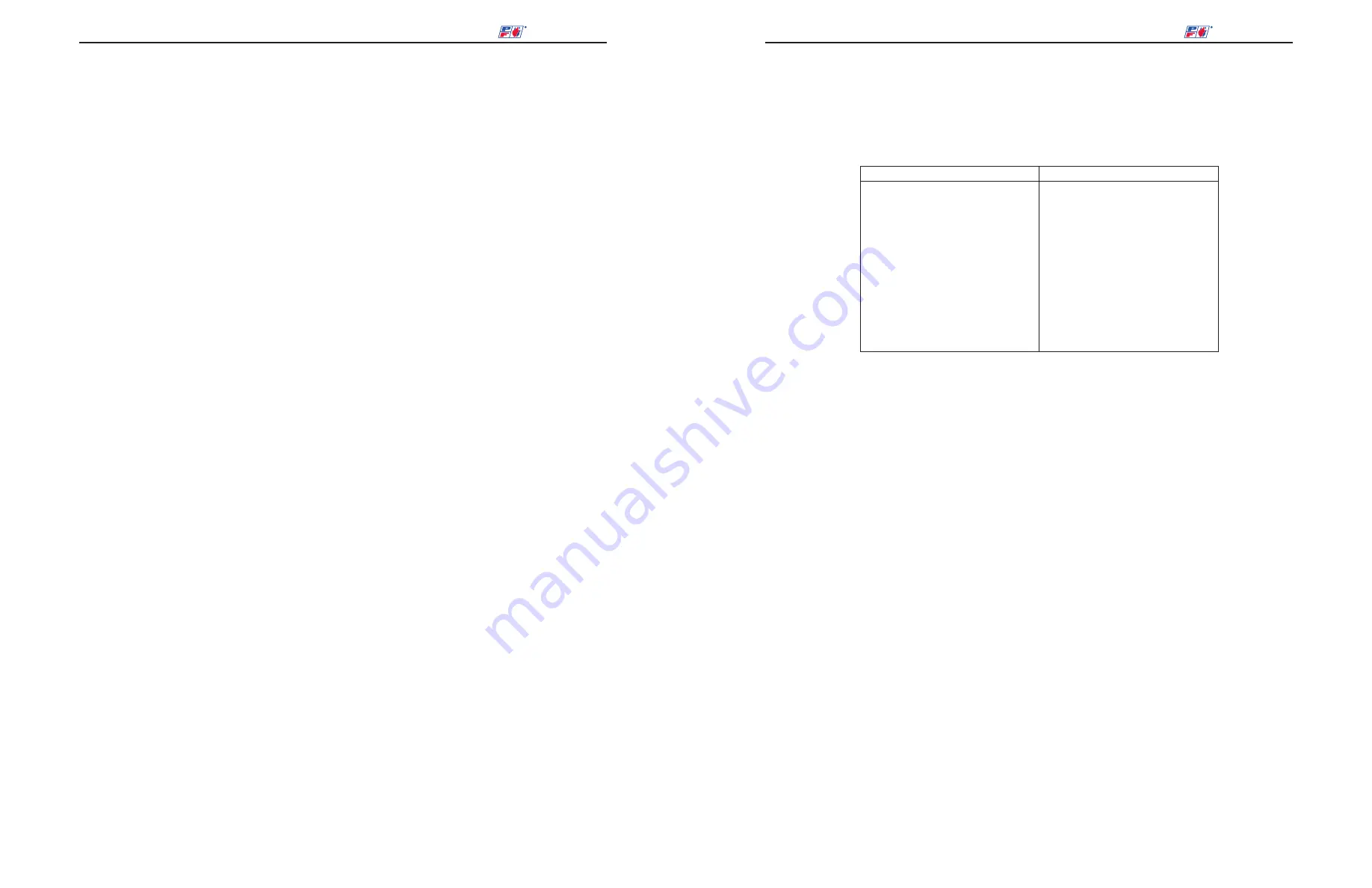

Table 3

Acceptable Stable Pilot and/or Main Flame Current Readings

Control

U.V.

Infrared

R7800

1.25-5.0 DC Volts

1.25-5.0 DC Volts

E

MK7

5 min., 10 or greater normal

5 min., 10 or greater normal

110

10 min., 20 or greater normal

10 min., 20 or greater normal

15.

TROUBLE SHOOTING SUGGESTIONS

1.

Burner Fails to Start

A.

Defective On/Off or fuel transfer switch. Replace

B.

Control circuit has an open control contact. Check limits, low water cutoff, proof

of closure switch and others as applicable.

C.

Bad fuse or switch open on in-coming power source. Correct as required.

D.

Motor overloads tripped. Reset and correct cause for trip out.

E.

Flame safeguard control safety switch tripped out. Reset and determine cause

for apparent flame failure.

F.

Loose connections or faulty wiring. Tighten all terminal screws and consult

wiring diagram furnished with the burner.

G.

Flame safeguard control starting circuit blocked due to flame relay being

energized. Possible defective scanner – replace. Possible defective amplifier –

replace. Scanner actually sighting flame due to leaking fuel valve – correct

unwanted flame cause. Defective flame safeguard control – replace.

H.

Defective blower motor. Repair or replace.

I.

LFI air switch open. Verify damper is in the low fire position or reset switch.

2.

Occasional Lockouts For No Apparent Reason

A.

Gas pilot ignition failure. Refer to pilot adjustment section and readjust to make

certain that the ignition is instant and that flame signal readings are stable and

above minimum values. Use a manometer or 0 to 10” W.C. gas pressure gauge

on pilot test tee to make certain that pressure is as recommended.

B.

Gas pilot ignition. Verify that there are no cracks in the porcelain and that

transformer end and electrode end plug in connections are tight.

C.

Loose or broken wires. Check all wire nut connections and tighten all terminal

screw connections in panel and elsewhere as appropriate.

D.

Ensure that when main flame lights, the air flow switch is not so critically set as to

allow occasional momentary opening of the air switch contacts.

10

NOVA PLUS Installation & Operation Manual -

POWER FLAME INCORPORATED

DC4 DRAFT CONTROL

ENTER

ESC

®

12. BURNER START UP AND SERVICE TEST EQUIPMENT REQUIRED

The following test equipment is required to ensure proper start up and adjustment of burner

equipment to obtain maximum efficiency and reliability of operation.

For any Gas

Flue Gas Analyzer with O

2

,

NOx, CO capability (Required)

Stack thermometer

Draft gauge or inclined

Manometer

Combination volt/ammeter

D.C. microammeter or D.C.

U-Tube manometer 0-16”

W.C. or calibrated 0-10” and

0-35” W.C. pressure gauges.

PSIG 0-5#

(Higher pressure ranges may

be necessary depending upon

gas inlet supply pressure)

Voltmeter, as required by

Flame safeguard

Measure the excess O

2

and test for CO to make certain that the burner is adjusted so that it has an

excess 0

2

of typically 6% to 9% when firing without FGR (flue gas recirculation). The excess 0

2

level

when using FGR will typically be 5% to 7%. This is the typical excess O

2

range required for the premix

burner to obtain reduced NOx emissions. If higher excess O

2

is required to obtain a particular emission

level the CO level must be checked thoroughly. CO is a dangerous product of incomplete combustion

and is associated with combustion inefficiency and increased fuel cost. Any CO readings on any fuel

should be near 0% or less than 50 ppm.

13.

BURNER START UP SEQUENCE INSTRUCTIONS

1.

Prior to burner start up – contact the local gas company to determine if any correction

factors have to be applied to their indicated meter flow rates. This information is important

as relates to achieving specific heat exchanger BTU/HR inputs.

Refer to Figure 2, page 4

and the burner rating plate for additional firing rate information.

2.

Refer to

Figure 6, page 11

for air switch locations and pressure settings.

3.

Refer to the gas piping diagram furnished with the burner. Check gas piping, controls and

valves for leaks and compliance with codes.

4.

Check all linkages and servo couplings for proper position and tightness

5.

Close main checking and pilot gas cocks. Install one gas pressure gauge on the manifold

(orifice tee) to read burner firing head pressure (use 0-32” W.C. gauge or a manometer).

Install a second gas pressure gauge to read gas supply pressure between the main gas

cock and the inlet to the main gas pressure regulator (use a 0-5 psi gauge or as

appropriate). If there is no tapping in this location, install a tee at the point where the pilot

gas supply is connected to the main gas line. Slowly open the main gas cock in order to

determine that the incoming gas pressure is within the specified limits of the main and pilot

gas pressure regulators, automatic fuel valves and gas pressure switches.