Page 14 of 35

Reference: 708052-1

Issue date: 23-Jul-2014

Revision: B

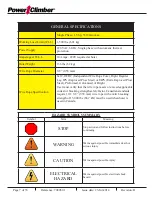

WARNING:

Use protective gloves to handle the steel wire ropes

Use only Power Climber-approved steel wire rope. Steel wires

ropes must be replaced in any of the following conditions:

•

More than 10 wires are broken on a length of 240mm

•

Excessive corrosion

•

Damage due to heat

•

Reduction of the nominal diameter by more than 10%

•

Kinking (1), crushing (2), bird caging (3) or any other

distortion of the wire rope structure.

Wire Rope Inspection Procedure

Wire Rope Inspection Procedure. The need for replacement of suspension wire ropes shall be determined by regular

inspection and shall be based on the condition of the wire rope inspected. Wire rope in active service should be

visually inspected once every working day. A thorough inspection shall be made once a month, or before each use

if the suspension wire ropes have been inactive for 30 days or longer and are placed into service. Dated and signed

monthly reports of that inspection must be kept, indicating the condition of the ropes.

Any of the following conditions, or combination of conditions, shall be considered as sufficient reason for the

removal of the wire rope from service:

CAN/CSA - Z271 7.7.4.1

Wire rope with one or more of the following defects shall be removed and replaced immediately.

1. Whenever there is severe corrosion. Any development of slight corrosion shall be noted and watched closely;

2. Whenever there are broken wires, as follows:

(a) When there is more than one valley break. A valley break is a wire break occurring in the valley

between two adjacent strands.

(b) Whenever there are six randomly distributed broken wires in one rope lay or three broken wires in one

strand in one rope lay. A rope lay is the length along the rope in which one strand makes a complete

revolution around the rope.

3. Whenever there are broken wires in the vicinity of attachments. If this condition is localized in an operating

rope, then the section in question may be eliminated by making a new attachment. This may be done rather

than replacing the entire rope.

4.

Whenever there is abrasion, scrubbing, flattening, or peening causing loss of more than one-third of the original

diameter of the outside wires.

5. When there are severe kinks, crushing, birdcaging, or other damage resulting in distortion of the rope structure.

6. Whenever there is evidence of any heat damage resulting from a torch or caused by contact with electrical

wires; and when the reduction from nominal diameter of the rope is:

(a) more than 1.2mm (0.047 in) for diameters up to and including 20mm (0.78 in)

(b) 1.5mm (0.059 in) for diameters 22 to 28 mm

(c) 2.5mm for diameters 32 to 40mm.