13

Changing the Engine Oil

Run the engine a few minutes before changing the

oil to warm it. Warm oil flows better and carries more

contaminants.

4. Place an oil drain pan under the oil drain plug, remove

the oil drain plug, and tip the snowthrower backward and

drain the used oil in the oil drain pan (Figure 23).

5. After draining the used oil, return the snowthrower to

the operating position.

6. Install the oil drain plug and torque to 145-150 in-lbs

(17 N-m).

NOTE:

Dipstick location may vary depending on engine

type.

7. Clean around the oil filler cap/dipstick (Figure 24).

8. Unscrew the oil fill cap/dipstick and remove it

(Figure 24).

9. With the snowthrower in the operating position, care-

fully pour oil into the oil fill hole until "Full" on the fill

cap/dipstick line (Figure 26).

Max fill: 18 oz. (0.5 l), type: automotive detergent oil with

an API service classification of SJ, SL, or higher.

Use Figure 25 below to select the best oil viscosity for

the outdoor temperature range expected:

Figure 24

1. Oil fill cap/dipstick

1

1

Figure 25

NOTE:

10W30 synthetic oil is acceptable for use in cold

temperatures.

10. Screw in the oil fill cap/dipstick and hand tighten it

securely.

11. Wipe up any spilled oil.

12. Dispose of the used oil properly at a local recycling

center.

The engine oil will be hot. Avoid skin contact

with the used engine oil.

Figure 23

1. Oil drain plug

1

1. Move snowthrower to a level surface.

2. Run snowthrower until all fuel has been depleted.

3. Remove ignition key.

Figure 26

Fill if oil is

below letter

“L” on the

¿OOHUFDS

Fill if oil

is below

“Add”

on the

GLSVWLFN

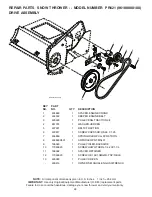

Summary of Contents for 436414

Page 27: ...27 SERVICE NOTES...