12

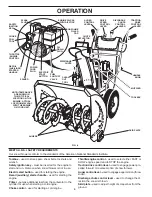

OPERATION

COLD START - ELECTRIC STARTER

1. Insert safety ignition key (packed separately in parts

bag) into ignition slot until it clicks. DO NOT turn the key.

Keep the extra safety ignition key in a safe place.

2. Place throttle control in FAST position.

3. Rotate choke control to FULL position.

4. Connect the power cord to the engine.

5. Plug the other end of the power cord into a three-hole

grounded 120 Volt A.C. receptacle.

6. Push the primer three (3) times.

7. Push starter button until engine starts.

IMPORTANT

: Do not crank engine more than five con-

tin u ous seconds between each time you try to start. Wait

5 to 10 seconds between each attempt.

8. When the engine starts, release the starter button and

slowly move the choke control to the “OFF” position.

9. Disconnect the power cord from the receptacle first,

then from the engine.

Allow the engine to warm up for a few minutes. Engine will

not develop full power until it has reached normal operat-

ing temperature.

WARM START - ELECTRIC STARTER

Follow the steps above, keeping the choke control in the

OFF position.

COLD START - RECOIL STARTER

1. Insert safety ignition key (packed separately in parts

bag) into ignition slot until it clicks. DO NOT turn the key.

Keep the extra safety ignition key in a safe place.

2. Place throttle control in FAST position.

3. Rotate choke control to FULL position.

4. Push the primer four (4) times if the temperature is

below 15°F, or two (2) times if temperature is between

15° and 50°F. If temperature is above 50°F, priming is

not nec es sary.

NOTE

: Over priming may cause flooding, preventing the

engine from starting. If you do flood the engine, wait a few

minutes be fore at tempt ing to start and DO NOT push the

primer.

5. Pull recoil starter handle quickly. Do not allow starter

rope to snap back.

6. When the engine starts, release the recoil starter

han dle and slowly move the choke control to the OFF

position.

Allow the engine to warm up for a few minutes. Engine will

not develop full power until it has reached normal operat-

ing temperature.

WARM START - RECOIL STARTER

Follow the steps above, keeping the choke in the OFF

position. DO NOT push the primer.

BEFORE STOPPING

Run the engine for a few minutes to help dry off any mois-

ture on the engine.

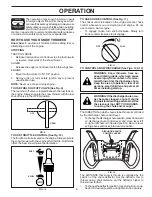

IF RECOIL STARTER HAS FROZEN

If the recoil starter has frozen and will not turn the engine,

proceed as follows:

1. Grasp the recoil starter handle and slowly pull as much

rope out of the starter as possible.

2. Release the recoil starter handle and let it snap back

against the starter.

If the engine still fails to start, repeat the above steps or

use the electric starter.

SNOW THROWING TIPS

• Always operate the snow thrower with the engine at

full throttle. Full throttle offers the best performance.

•

Go slower in deep, freezing or heavy wet snow. Use the

drive speed control, NOT the throttle, to adjust speed.

• It is easier and more efficient to remove snow im me -

di ate ly after it falls.

•

The best time to remove snow is the early morning. At

this time the snow is usually dry and has not been ex-

posed to the direct sun and warming tem per a tures.

• Slightly overlap each successive path to ensure all

snow will be removed.

• Throw snow downwind whenever possible.

• Ad

just the skid plates to proper height for current snow

con di tions. See “TO ADJUST SKID PLATES” in this

section of this manual.

•

For extremely heavy snow, re duce the width of snow re-

moval by over lap ping previous path and moving slowly.

•

Keep engine clean and clear of snow during use. This

will help air flow and extend engine life.

•

After snow-throwing is completed, allow engine to run for

a few minutes to melt snow and ice off the engine.

• Clean the entire snow thrower thoroughly after each

use and wipe dry so it is ready for next use.

WARNING: Do not operate snow

thrower if weather conditions im pair vis-

ibility. Throwing snow dur ing a heavy,

windy snowstorm can blind you and be

hazardous to the safe operation of the

snow thrower.

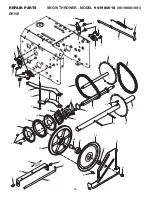

Summary of Contents for 415332

Page 19: ...19 SERVICE NOTES...

Page 32: ...32 REPAIR PARTS SNOW THROWER MODEL 961980018 96198001801 DECALS...

Page 34: ...34 SERVICE NOTES...

Page 35: ...35 SERVICE NOTES...