3. Installation Requirements – Page 7

To size the expansion vessel it is first necessary to calculate

the volume of water in the system in litres. The following

volumes may be used as a conservative guide to calculating

the system volume.

Boiler Heat Exchanger:

4 litres

Small Bore Pipework:

1 litre per kW of system

output

Micro Bore Pipework:

7 litres

Steel Panel Radiators:

8 litres per kW of system

output

Low Water Capacity Radiators:

2 litres per kW of system

output

Hot Water Cylinder:

2 litres

If the system is extended, the expansion vessel volume may

have to be increased unless provision has been made for

extension. Where a vessel of the calculated size is not

available, the next available larger size should be used.

The boiler flow temperature is controlled at approximately

82°C.

The vessel size can now be determined from the information

in Table 1 where V = System volume in litres.

Cylinder

The hot water cylinder must be an indirect coil type or a

direct cylinder fitted with an immersion calorifier suitable for

operating at a gauge pressure of 0.3 bar (5 lbf/in

2

) in excess

of safety valve setting. Single feed indirect cylinders are not

suitable for sealed systems.

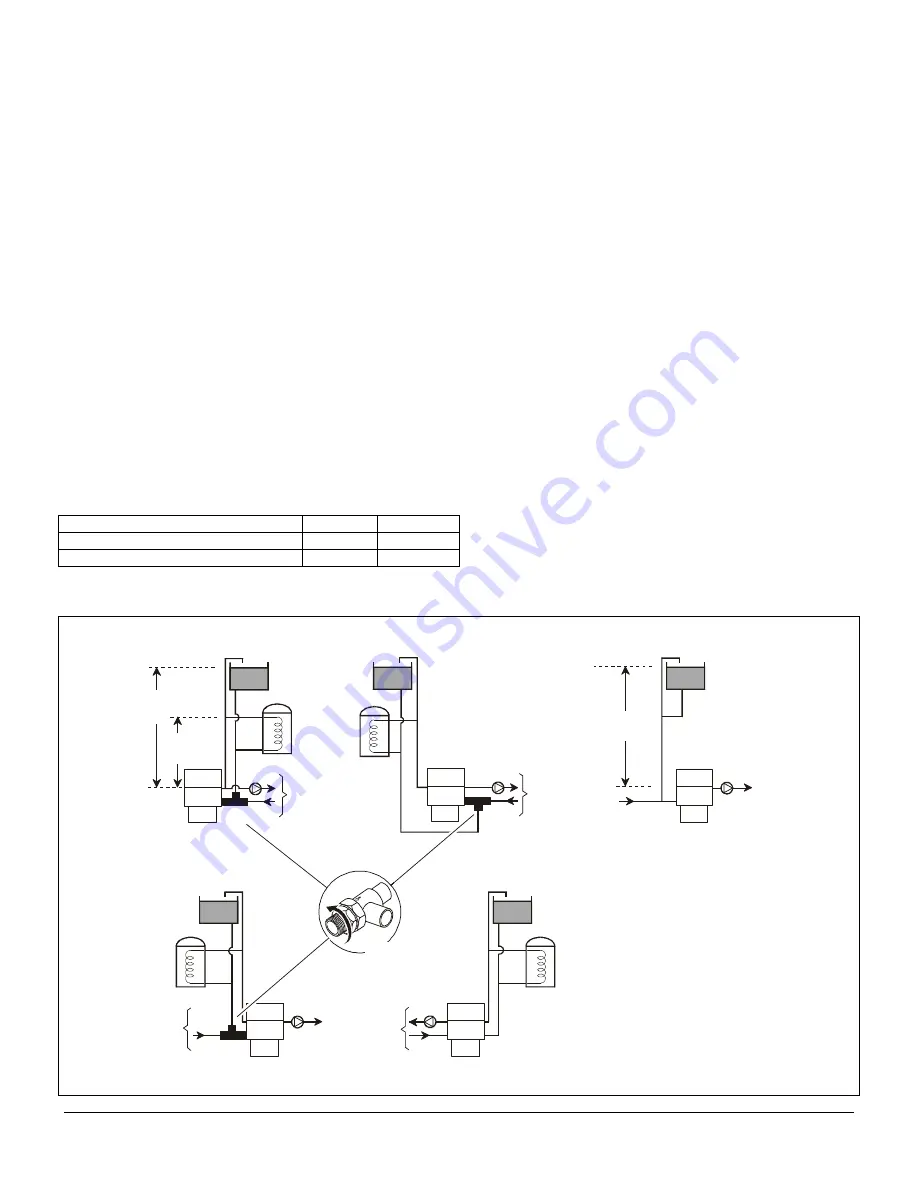

Method of Make-up

Provision shall be made for replacing water loss from the

system either:

i)

from a make-up vessel or tank mounted in a position

higher than the top point of the system, and connected

through a non-return valve to the system on the return

side of the hot water cylinder or the return side of all

heat emitters. or

ii)

where access to a make-up vessel would be difficult by

using the mains top up method or a remote automatic

pressurisation and make-up unit as shown in

Figs. 7 & 8.

Mains Connection

There shall be no connection to the mains water supply or to

the water storage tank which supplies domestic hot water

even though a non-return valve, without the approval of the

Local Water Authority.

Vessel Charge Pressure (bar)

0.5

1.5

Filling Point

Initial System Pressure (bar)

1.0

1.0

The system shall be fitted with a filling point at low level

Expansion Vessel Volume (litres)

V x 0.11

V x 0.087

which incorporates a stop valve to BS 1010 and a double

Table 1.

check valve (approved by the National Water Council) to be

fitted in this order from the system mains, see Fig. 7.

Flow

Flow

Return

Return

Central

Heating

Central

Heating

In

je

c

to

r

T

e

e

In

je

c

to

r

T

e

e

1.2

Metres

Min.

30.5

Metres

Max.

Water Level

Heat

Exchanger

Heat

Exchanger

Flow

Return

Central

Heating

Flow

Return

Central

Heating

Heat

Exchanger

30.5M Max.

0.9M Min.

Water Level

Flow

Fully

Pumped

System

Return

Heat

Exchanger

Heat

Exchanger

BBU Open Vented

System Variants

All Systems Illustrated

Can Be Fitted To The

Other Side Of the Boiler

On Combined Gravity

D.H.W. Pumped Heating

Systems The Injector

Tee Is To Be Fitted

Directly To The Boiler.

The Tee On The

Combined Flows Is

To Be Fitted As Close

To The Boiler As Possible

B

B

4

5

0

0

4

C

Injector Tee

can be installed

in any direction

see Fig 14

Fig 3

Summary of Contents for Housewarmer 45

Page 17: ...4 Installation Page 17 ...

Page 25: ...8 Electrical Diagrams Page 25 ...

Page 34: ...Installation Page 7 ...

Page 35: ...Installation Page 8 ...