PP2000 (E) User’s Manual

6 - 5

H.

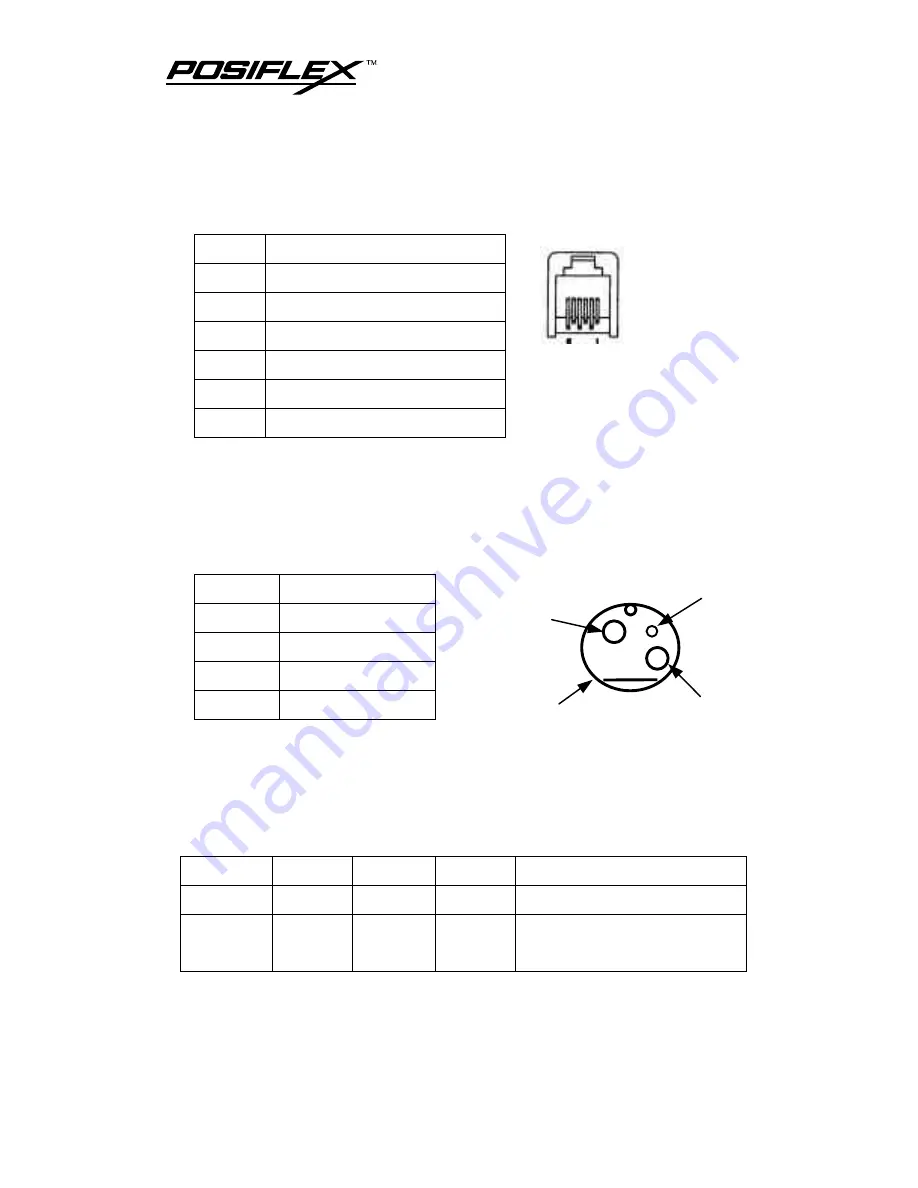

CASH DRAWER CONNECTOR

PIN

DEFINITION

1

Frame ground

2

CR2 kick (by Esc p 0 n1 n2)

3

Drawer open sense

4

+24V DC power

5

CR1 kick (by Esc p 1 n1 n2)

6

Signal ground

I.

SERIAL INPUT CONNECTOR

(standard 9 pin RS232 interface)

J.

POWER INPUT CONNECTOR

PIN

DEFINITION

1

+24 V DC power

2

Power ground

3

N. C.

CASE

Frame ground

K.

PARALLEL INPUT CONNECTOR

(standard 25 pin SPP interface)

L.

DIMENSION AND WEIGHT

Length

Width

Height

Weight

PRINTER 265 mm 176 mm

193 mm 2.5 Kg

PACKED 315 mm 240 mm

320 mm

3.8 Kg (w/o power adaptor)

4.5 Kg (w/ power adaptor)

1

3

CASE

2

Summary of Contents for PP2000 Series

Page 1: ...Rev A PP2000 Series 2 Station Printer User s Guide ...

Page 16: ......