Page 10

make sure that the scanner is installed as instructed in this manual and that all cables are

properly connected. If the problem remains, contact your dealer.

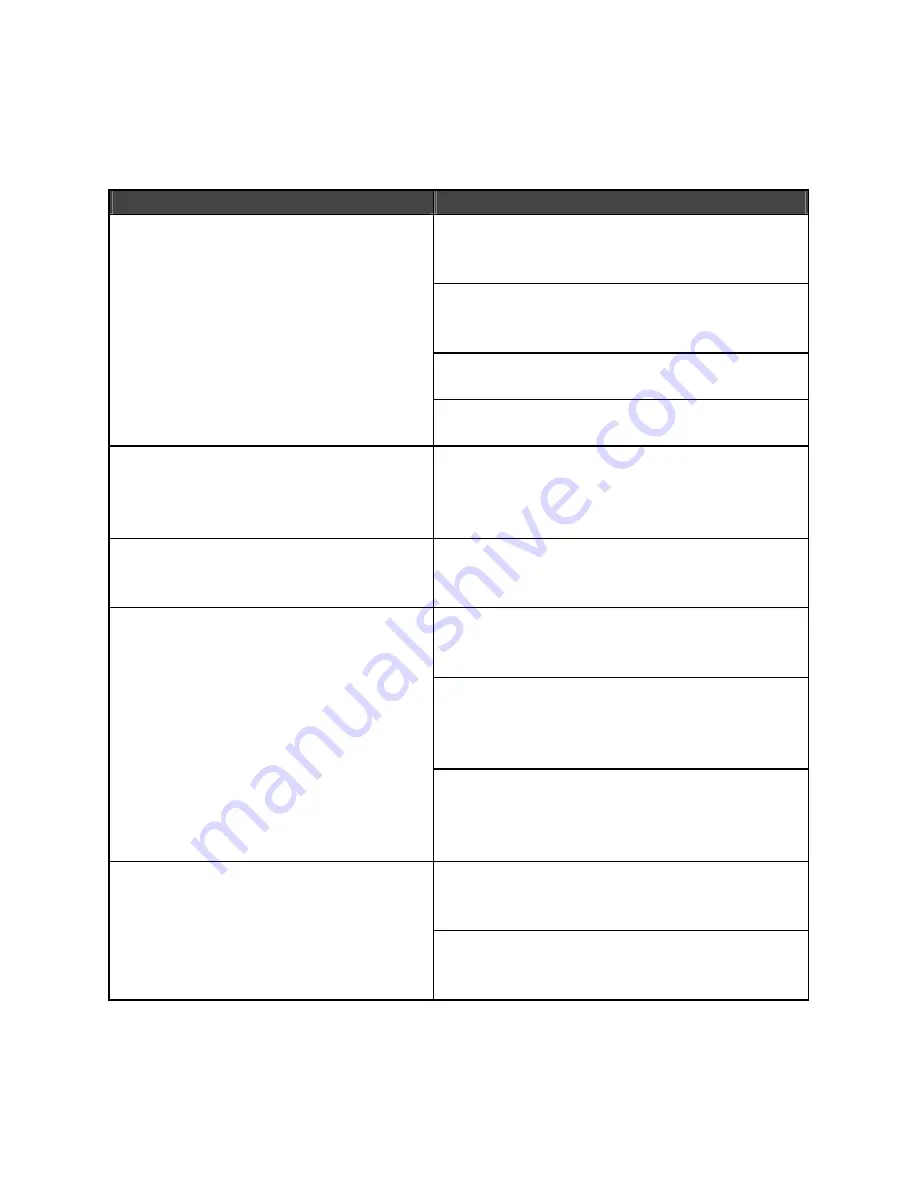

Problem

Diagnostic Tips

The scanner window is dirty. Clean the

scanner window as described in the

Maintenance section.

The presented barcode type is not enabled.

Use the Programming Guide to tell the

scanner to accept that type of barcode.

The host has disabled the scanner. Check host

setup.

The scanner is on but cannot read

barcodes.

The LED stays blue

The barcode type presented is not supported

by the scanner.

The scanner is on, but the motor is not

running; the facet wheel is not rotating.

A barcode cannot be read.

The LED is intermittently flashing blue.

The scanner has entered into the sleep mode.

Press the function button to wake up the

scanner, or present an object close to the scan

window.

The LED remains red and blue

(purple).

Possible failure of the scanning safeguard

circuit. Disconnect the scanner from its power

source immediately and contact your dealer.

There is no proper handshaking with the POS

system. Check connection and communication

settings of the host POS system.

A stray barcode is sitting somewhere in the

scanner field of view. Remove all barcode

labels from the scanner’s scan volume and try

again.

The scanner does not accept more than

two or three bar-code labels.

The scanner cannot send the data to the POS

system. Make sure that all cables are

connected and your host POS system is ready

to receive data.

The communication settings of the system

port and the scanner do not match. Adjust the

settings so they match.

A barcode is read by the scanner but

not accepted by the POS system.

The communication cable used is incorrect.

Contact your dealer for the correct

communication cable.

Summary of Contents for LS-1000 Series

Page 15: ...Full ASCII CODE 39 Disable Code 39 Enable Code 39 Disable Full ASCII CODE39 Enable Page 15 ...

Page 16: ...UPC EAN JAN Disable UPC EAN JAN Enable ITF 2 OF 5 Disable ITF 2 of 5 Enable Page 16 ...

Page 17: ...UPC EAN ADD ON OFF ADD ON 5 only ADD ON 2 only ADD ON 2 or 5 Page 17 ...

Page 20: ...Code 128 Enable Code 128 Disable Code 93 Enable Code 93 Disable Page 20 ...

Page 22: ...MSI enable MSI Disable Enter Exit Programming Mode Page 22 ...