17

Fig. M

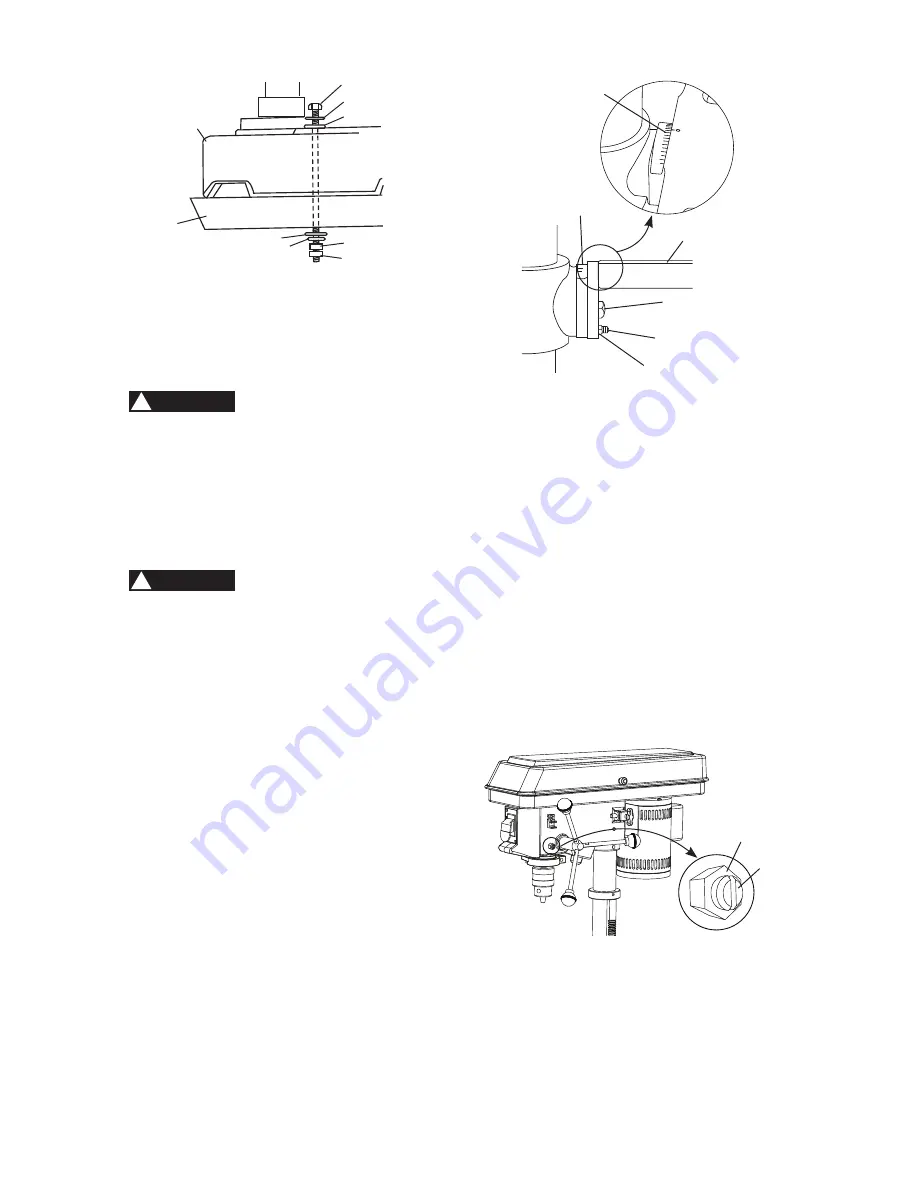

SPINDLE / QUILL (FIG. N)

Rotate the feed handles counterclockwise

to lower spindle to its lowest position. Hold

the chuck and move it front to back. If there

is excessive play, proceed with the following

adjustments:

1. Loosen the lock nut (1) located on the

right side of the drill press by using a

10 mm wrench.

2. Turn the screw (2) clockwise to eliminate

the play, using a slotted screwdriver, but

without obstructing the upward movement

of the spindle. (A little play in the spindle

is normal.)

3. Tighten the lock nut (1).

Fig. N

Fig. L

ADJUSTMENTS INSTRUCTIONS

NOTE:

All the adjustments for the operation

of the drill press have been completed at the

factory. Due to normal wear and use, some

occasional readjustments may be necessary.

To avoid injury from an accidental start,

ALWAYS make sure the switch is in the

“OFF” position, the switch key is removed,

and the plug is not connected to the power

source outlet before making adjustments.

BEVEL DRILLING (FIG. M)

To prevent personal injury, always

disconnect the plug from the power

source when making any adjustments.

NOTE:

A bevel scale has been included

to measure approximate bevel angles. If

precision is necessary, a square or other

measuring tool should be used to position

the table. To use the bevel scale (1):

1. TIGHTEN the nut (2) on the locking pin (3)

using a 10 mm or adjustable wrench

clockwise to RELEASE the locking pin (3)

from the table support.

2. Loosen the bevel lock bolt (4) using a

17 mm or adjustable wrench.

3. Tilt the table (5) to desired bevel angle

that will shown on the bevel scale (1).

4. Tighten the bevel lock bolt (4).

5. To return the table to horizontal position,

loosen the bevel lock bolt (4), return the

table (5) to the 0° position.

6. Return the nut (2) on locking pin (3) to the

OUTSIDE END OF THREADS. Gently

tap locking pin (3) until it is seated in the

mating hole of the table bracket. Hand

tighten the nut (2).

WARNING

!

1

2

5

3

4

6

7

8

9

WARNING

!

5

2

4

1

1

3

1

2