PONNDORF Gerätetechnik GmbH

Leipziger Strasse 374

D - 34123 Kassel

Operation manual

Hose Pump type

P_high pressure 65

Page 23 of 26

Version 002_GB / 05.2017

7. Maintenance / Service

There are no sophisticated procedures of maintenance necessary for Ponndorf Hose

Pumps.

Nevertheless there have to be made regular inspections in order to avoid any decrease of

capabilities of the pump (e.g. suction capacity / discharge head / flow rate).

7.1 Changing the pump hose

When changing the pump hose please consider chapter 6.4 (Installing / changing of the

pump hose).

Remove power from the pump by removing the main fuses before doing

any cleaning / maintenance / assembly operations !

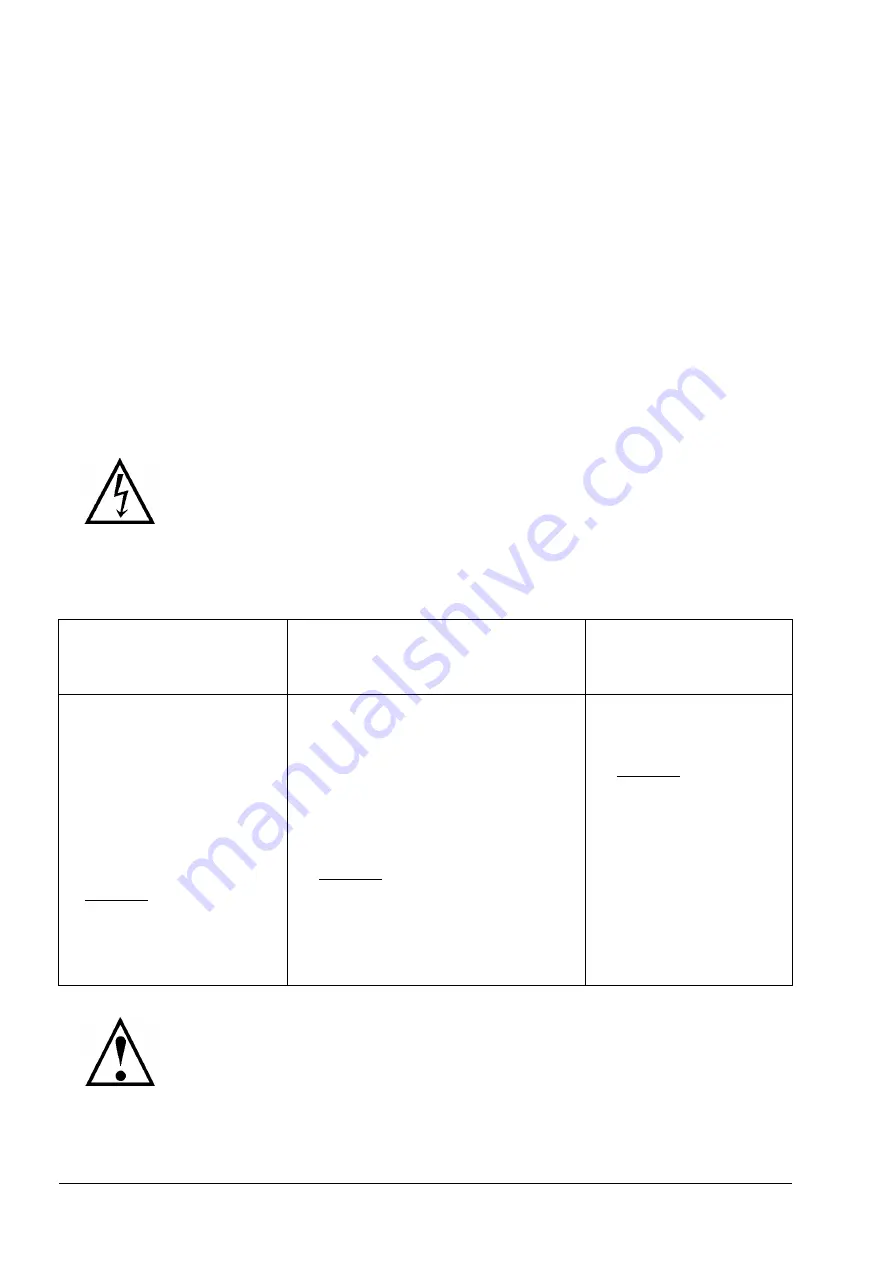

7.2 Maintenance

Filling of lubricant bath

Rotor bearings

Inspection glass

• check on sufficient liquid

level (max. 25 liter

approx.)

• see also page 23

(chapter

6.5, picture 13)

• interval:

every 300 hours of

operation

• check on proper seat

of bearings

• check on inadmissible

development of heat

• check on inadmissible

noise development of bearings

• interval:

every time when

changing the pump

hose respectively every 500

hours of operation

• check on intactness

• interval:

every 500 hours of

operation

In case of wear characteristics mentioned above rotor bearings must be

replaced!