Automatic boiler for wood pellets

23

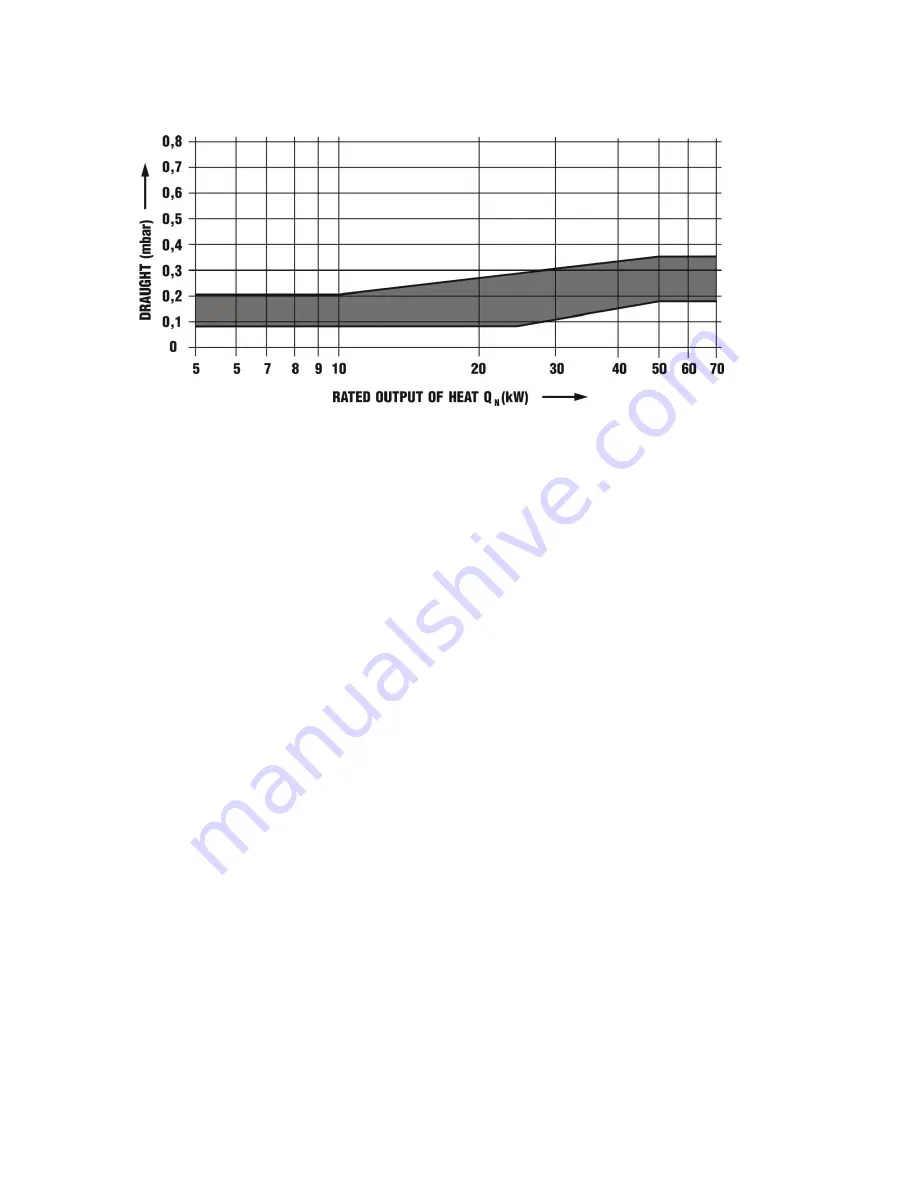

Recommended draught of chimney has to be within the range specified by the manufacturer in connection with the

installed power output of the boiler.

Picture No. 16 Required chimney draft

Chimney systems resistant to humidity in which condensation of water vapour is permitted are recommended in order to

ensure long-term trouble-free and safe operation of the boiler. (Chimneys resistant to humidity are recommended for

appliances with temperature of combustion products from 30°C to 100°C.)

4.3.3

Fire regulations

EN 13501-1 Fire classification of construction products and building elements – Part 1: Classification using data from

reaction to fire tests

EN 13501-2 Fire classification of construction products and building elements – Part 2: Classification using data from fire

resistance tests, excluding ventilation services

4.3.4

Electrical

EN 60 335-1 ed.2.20073 – Electrical appliances for domestic and other similar use – Safety - General requirements.

EN 60 335-2-102:2007- Safety – Part 2-102: Special requirements for appliances burning gas, petroleum and solid fuels

containing electrical connections.

4.3.5

Protection against noise

Government Regulation no. 148/2006 Coll. – product is fulfilling all requirements.

4.4

STORAGE OF FUEL

Wood pellets have to be in a dry place protected against atmospheric effects because humidity damages the aggravates

their burning parameters. Excessive humidity completely destroys pellets. They should be stored in a different room than

the boiler or at least 1,500 mm from the boiler.

Operating stock of fuel may be stored in a special central bin which has to be manufactured from non-combustible

material. Bins supplied by the manufacturer meet operating and safety requirements. They may be filled without any

limits up to their total volume.

Large-volume bins have to meet corresponding fire and safety regulations. The supplier is obliged to work out working

regulations and instructions for operation and maintenance of large-volume bins.

4.5

BOILER ROOM VENTILATION

Permanent ventilation of the boiler within approximately 75 m

3

x hour

-1

of fresh air has to be ensured, if a boiler of

approximately 20 kW of power output is operated.

Summary of Contents for KP 12S

Page 1: ......

Page 17: ...Automatic boiler for wood pellets 16 Picture No 9 Feeder F1 4 5 1 4 5 2 4 5 3 4 5 4 4 5 5 ...

Page 28: ...Automatic boiler for wood pellets 27 Picture No 20 Ceramic grate parts placement guide ...

Page 41: ...Automatic boiler for wood pellets 40 8 3 1 2 Menu users settings ...

Page 43: ...Automatic boiler for wood pellets 42 Cleaning an ash removing Skin Time window setting ...

Page 46: ...Automatic boiler for wood pellets 45 Actual values Configuration ...

Page 52: ...Automatic boiler for wood pellets 51 Cleaning Ash removing USB Time window setting ...

Page 53: ...Automatic boiler for wood pellets 52 Load from USB Save on USB ...

Page 58: ...Automatic boiler for wood pellets 57 ...

Page 60: ...Automatic boiler for wood pellets 59 ...

Page 61: ...Automatic boiler for wood pellets 60 i ...

Page 63: ...62 Picture No 24 Principle of the modulation ...

Page 64: ...63 Picture No 25 Directory information consumption wood pellets for boiler family KP ...

Page 65: ...64 Picture No 26 Circuit diagram control unit ...

Page 66: ...65 Picture No 27 Circuit diagram module HZS 533 ...

Page 67: ...66 Picture No 28 Circuit diagram HZS 533 HZS 535 ...

Page 73: ...72 11 APPENDIX 2 REPORT ON THE PUTTING THE BOILER KP INTO OPERATION ...

Page 74: ...73 12 APPENDIX 3 SELF ADHESIVE LABEL IMPORTANT SAFETY INFORMATION ...