Automatic boiler for wood pellets

11

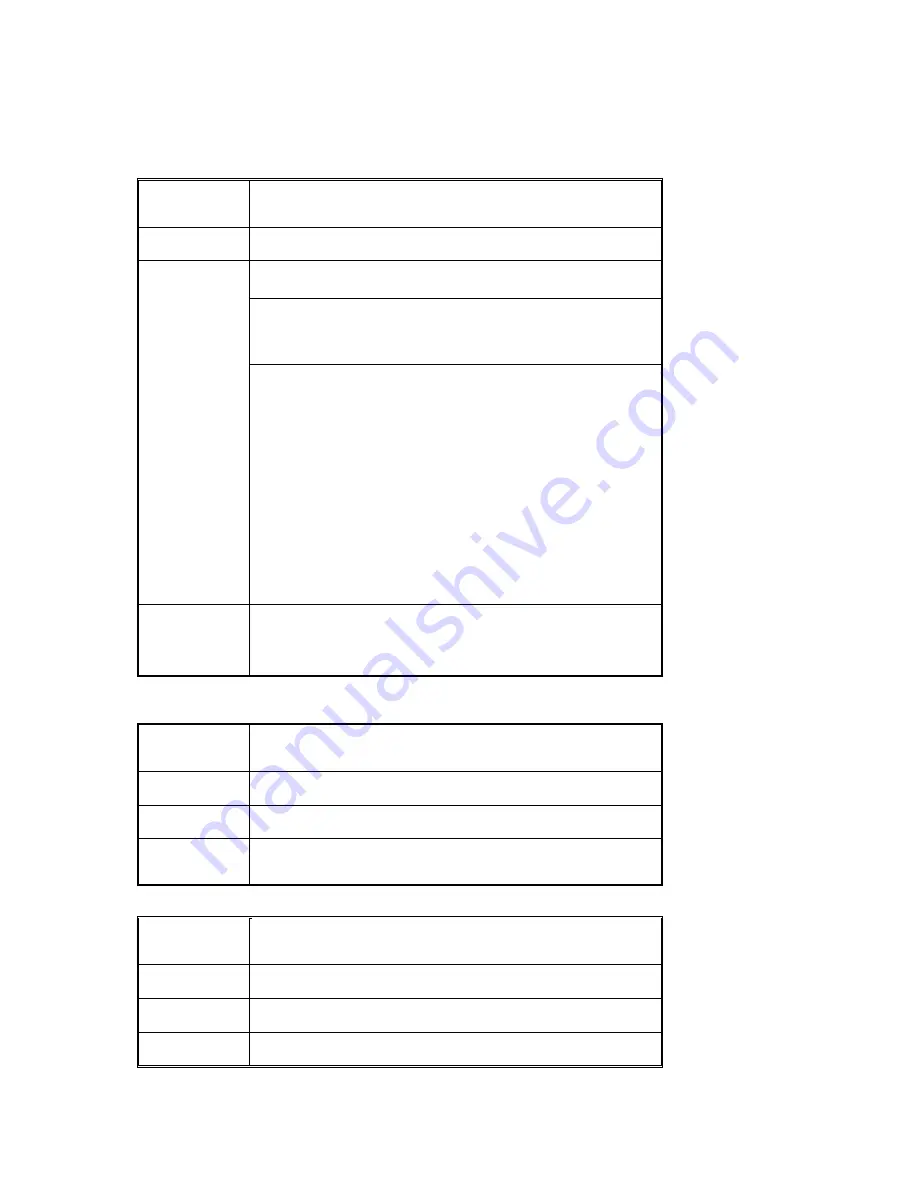

3.2.1.1

Technical base data

HZS521-G

Supply voltage

230 V AC +/- 10 %

(Input voltage for the power transformer on the power board, input

voltage for the STB, phase for the phase angle, relays and Triac outputs)

Power supply fre-

quency

45 - 65 Hz

Current

consumption of

supply (230 V AC)

Total current consumption 200 mA + current consumption of the

connected loads (max. 16 A)

Power supply transformer

Supply for the power board and CPU electronics

Supply for Heater Lambda sensor: 200 mA

The power supply is switched of STB, L-STB

Loads connected over fuse F4 (3,15 AT):

X11 primary fan: maximum

690 W/ maximum 3 A

Loads connected over fuse F5 (10 AT):

X14

Screw: maximum 690W/ maximum 3 A

Loads connected over fuse F6 (10 AT):

X9 Turbine: maximum 2300 W/

maximum 10 A

Loads connected over fuse F7 (10 AT):

X8 Ignition: maximum 2300 W/

maximum 10 A

Loads connected over fuse F8 (10 AT):

X5 heat exchange cleaner: maximum 690 W/

maximum 3 A

X6 grate open: maximum 690 W/

maximum 3 A

X7 grate closed: maximum 690 W/

maximum 3 A

The power supply not switched over STB, L

Loads connected over fuse

F9 (10 AT):

X10 boiler circuit return flow pump: maximum 2300 W/

maximum 10 A

HZS532-1

Internal

electronics power

supply

+24 V (from HZS 511), must be connected to the expansion

controller

Relay power

supply

230 VAC

Fuse

10 A for relay outputs

+24 V current

consumption

HZS 532-1: maximum 60 mA (without relays) Maximum

120 mA (with relays) HZS 532-1 with 5 expansion modules,

maximum 350 mA

HZS533, HZS535

Internal

electronics power

supply

+24 V (from HZS 511), must be connected to the expansion

controller

Relay power

supply

230 VAC

Fuse

5 A for relay outputs and/or 3 A for solar module

+24V

current

consumption

HZS 533 maximum 15 mA (without relays) Maximum 40

mA (with relays)

Summary of Contents for KP 12S

Page 1: ......

Page 17: ...Automatic boiler for wood pellets 16 Picture No 9 Feeder F1 4 5 1 4 5 2 4 5 3 4 5 4 4 5 5 ...

Page 28: ...Automatic boiler for wood pellets 27 Picture No 20 Ceramic grate parts placement guide ...

Page 41: ...Automatic boiler for wood pellets 40 8 3 1 2 Menu users settings ...

Page 43: ...Automatic boiler for wood pellets 42 Cleaning an ash removing Skin Time window setting ...

Page 46: ...Automatic boiler for wood pellets 45 Actual values Configuration ...

Page 52: ...Automatic boiler for wood pellets 51 Cleaning Ash removing USB Time window setting ...

Page 53: ...Automatic boiler for wood pellets 52 Load from USB Save on USB ...

Page 58: ...Automatic boiler for wood pellets 57 ...

Page 60: ...Automatic boiler for wood pellets 59 ...

Page 61: ...Automatic boiler for wood pellets 60 i ...

Page 63: ...62 Picture No 24 Principle of the modulation ...

Page 64: ...63 Picture No 25 Directory information consumption wood pellets for boiler family KP ...

Page 65: ...64 Picture No 26 Circuit diagram control unit ...

Page 66: ...65 Picture No 27 Circuit diagram module HZS 533 ...

Page 67: ...66 Picture No 28 Circuit diagram HZS 533 HZS 535 ...

Page 73: ...72 11 APPENDIX 2 REPORT ON THE PUTTING THE BOILER KP INTO OPERATION ...

Page 74: ...73 12 APPENDIX 3 SELF ADHESIVE LABEL IMPORTANT SAFETY INFORMATION ...