90

MAINTENANCE AND LUBRICATION

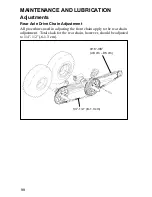

Adjustments

Toe Alignment

You can check the toe alignment of the

vehicle using the following method.

The recommended toe alignment is

1/8

″

to 1/4

″

toe out. If you discover

improper adjustment have your dealer

correct it.

1. Set handlebars in a straight ahead

position and hold them in this posi-

tion.

NOTE:

The steering frog can

be used as an indicator of whether

the handlebars are straight. The

frog should always point straight

back from the steering post.

2. Place stands in front of the ma-

chine, perpendicular to the rear

tires.

3. Tie an elastic string around the

stands, making sure string just

touches side surface of the rear tires

on each side of machine and goes

around the stands in front of the

machine.

4. Measure from string to rim at front and rear of front rim. Rear rim mea-

surement should be 1/16

″

- 1/8

″

(.2 to .3 cm) more than front rim mea-

surement.

WARNING

Do not attempt to adjust the tie rod for toe alignment. Severe injury

or death can result from improper adjustment. Contact your Polaris

dealer. He/she has the training and tools to make these

adjustments.

Summary of Contents for 2002 Sportsman 6x6

Page 1: ......

Page 3: ...Indicates a potential hazard that could result in serious injury or death WARNING...

Page 18: ...15 SAFETY Safety Decals and Locations 3...

Page 20: ...17 SAFETY Safety Decals and Locations 4 5 6 7 8...

Page 123: ...120 WIRING DIAGRAM...

Page 131: ......