0000112606/010720/A ControlPro

9

Scope of supply

Cable #2

Cable Panel

SlaveBoard, incl. cable gland

3x

Cable gland M16 + nut

For installation of the pneumatic hoses

(filter pressure sensor); refer to par. 4.5

Screw plug + nut M20

For installation on the last filter module

Heat shrink tube 50 mm + 30 mm

Refer to “Shielded cables only:” on

page 7

Termination plug

Refer to Fig. 4.16B on page 10

Each SlaveBoard box contains two blind plugs and two

disposable cover caps on the sides. The final position of the

blind plugs depends on the connection sequence of the

SlaveBoards.

-

Connect the cable to the SlaveBoard first. Then

cut the cable to the necessary length.

-

Start to connect the filter module that is closest to

the Panel.

- Refer to Fig. IV on page 19 for an example of

the correct connection sequence.

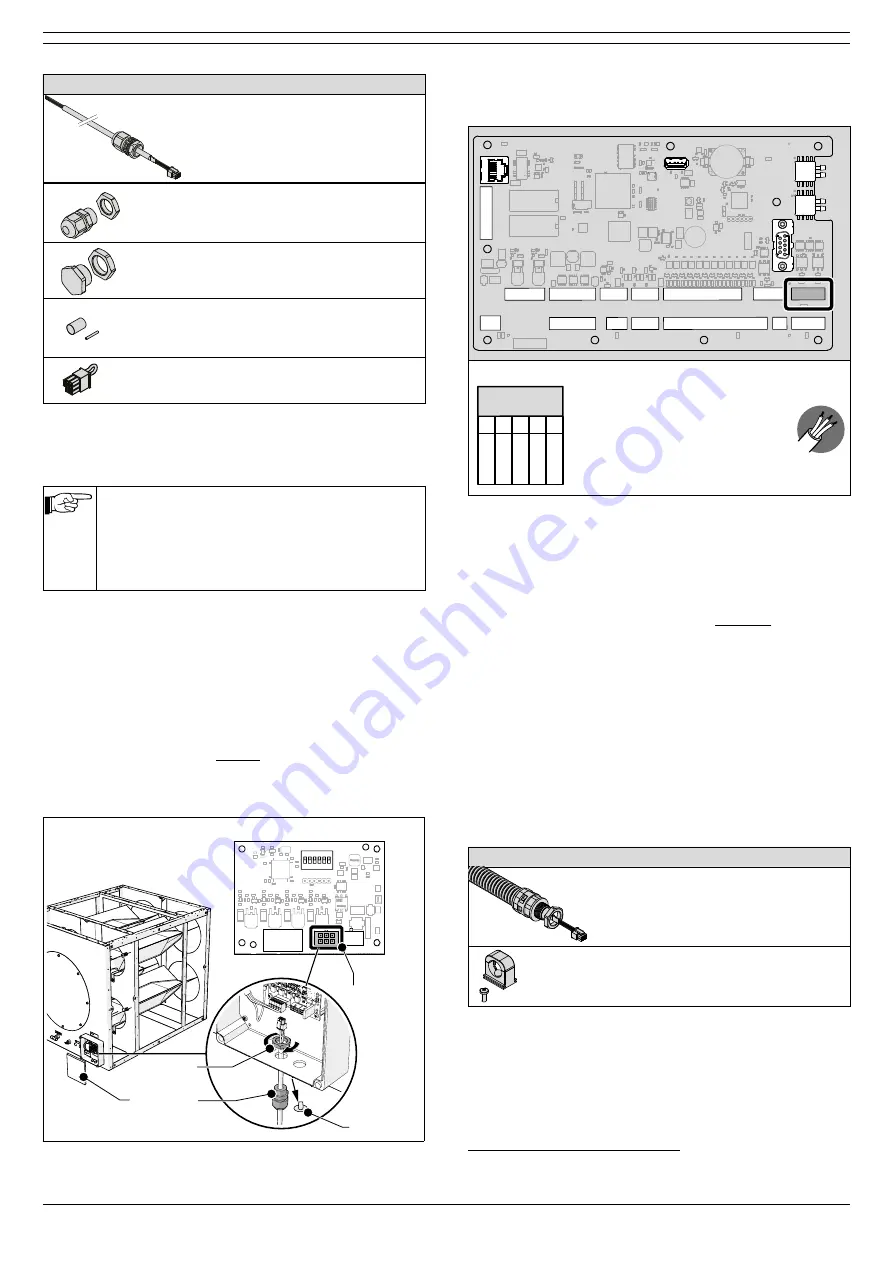

• Remove the lid (A) of the SlaveBoard box.

• Remove the two cover caps (E).

• If necessary, change the position of the blind plug(s).

• Loosen the cable gland (C) from the cable and remove the

nut.

• Put the cable into the SlaveBoard and put the nut (B) back

over the cable.

• Connect the cable to the CAN IN connector (D) on the PC

board.

• Tighten the cable gland.

Cable #2

A

D

(CAN IN)

E

C

B

Fig. 4.14 Connection of SlaveBoard

• Cut the cable to the necessary length for connection to the

Panel.

Indicator LED’s

Valves

Dustbin

sensor

Fan Pressure

sensor

Digital input 1-5

RS485 VFD

CAN Slave

CAN HMI

Digital input 6-12

Filter Pressure

sensor

Analog

output

Light tower

Power

Rel

ay

s

Cable #2

Indicator LED’s

Valves

Dustbin

sensor

Fan Pressure

sensor

Digital input 1-5

CAN Slave

CAN HMI

Digital input 6-12

Filter Pressure

sensor

Analog

output

Light tower

Power

Rela

y 1

R

ela

y 2

Ethernet

(for service only)

USB

(firmware updates)

RS-232

(for service only)

Filter pressure

(internal sensor)

Fan pressure

(internal sensor)

+

-

+

-

Valves

1

+ 24V

2

OUT 1

3

GND

4

+ 24V

5

OUT 2

6

GND

Indicator LED’s

1

+ 24V

2

PWR

3

RUN

4

ALA

5

WRN

6

+ 24V

7

BUZ

Dustbin

sensor

1

+ 24V

2

IN 1

3

GND

4

SHD

Fan Pressure

sensor

1

+ 24V

2

IN 2

3

GND

4

SHD

Analog

output

1

OUT

2

GND

3

SHD

1

+ 24V

2

IN 1

3

+ 24V

4

IN 2

5

+ 24V

6

IN 3

7

+ 24V

8

IN 4

9

+ 24V

10

IN 5

11

COM1

12

GND

Digital input 6-12

1

+ 24V

2

IN 6

3

+ 24V

4

IN 7

5

+ 24V

6

IN 8

7

+ 24V

8

IN 9

9

+ 24V

10

IN 10

11

+ 24V

12

IN 11

13

+ 24V

14

IN 12

15

COM2

16

GND

CAN Slave

1 2

CAN_H

3

CAN_L

4

GND

5

SHD

+ 24V

Power

+ 24V

2

GND

1

1 2

A

3

B

4

GND

5

SHD

RS485 VFD

8

1

NO 1

2

NC 1

3

COM 1

4

5

NO 2

6

NC 2

7

COM 2

Light tower

1

+ 24V

2

PWR

3

RUN

4

ALA

5

WRN

6

+ 24V

7

BUZ

Filter Pressure

sensor

1

+ 24V

2

IN 3

3

GND

4

SHD

CAN HMI

1 2

CAN_H

3

CAN_L

4

GND

5

SHD

+ 24V

8

Rela

y 1

R

ela

y 2

IN 5 External start/stop signal

IN 6 Fire alarm (ShieldControl)

IN 7 Sliding valve feedback 1

IN 8 Sliding valve feedback 2

IN 9 Fan alarm

IN 10 Compressed air switch

IN 11 External alert

IN 12 Dustbin level switch

SCS

:

cleaning v

alv

es (1 or 2)

MDB

: (only f

or ShieldC

on

tr

ol)

- out1

sliding v

alv

es

- out2

c

onpr

essed air r

elease

IN 1 BTN start/stop fan

IN 2 BTN filter cleaning

IN 3 Service mode switch

IN 4 Spare

Wiring colours

+24V

red

CAN_H

white

CAN_L

blue

GND

black

SHD

drain wire (with

shrink tube)

Fig. 4.15 Connection of SlaveBoard

Panel

In case of multiple filter modules

• Proceed with paragraph 4.4.5

In case of one (1) filter module

• Put the termination plug

22

(B) on the CAN OUT connector

on the PC board.

• Make sure that the DIP switches are correctly set.

• Close the lid.

4.4.5

SlaveBoard

SlaveBoard

In case of multiple filter modules, you must make a serial

connection of the cables.

The number of cables (cable #3) supplied is equal to the

number of filter modules, minus 1 (one). Each filter module

contains four screw holes for connection of the tube clamps.

Scope of supply

Cable #3

Cable SlaveBoard

SlaveBoard, including:

- conduit

- conduit connectors M20 + nuts

2x

Tube clamp + screw

22. Supplied with the Panel

SlaveBoard cable (#2)

23.

Address configuration pos. 1-4: according to number

1