TABLE OF CONTENTS

SCOPE

9

RELATED PUBLICATIONS

9

NOTICES

9

GENERAL DESCRIPTION

11

DRIVE CHARACTERISTICS

13

RACK MOUNT AND DESKTOP CONFIGURATIONS

13

TOWER CONFIGURATION

15

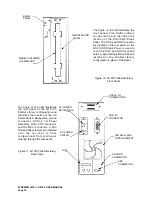

FILENET LIBRARY CONFIGURATION

17

PLASMON 1800 LIBRARY CONFIGURATION

19

DIMENSIONS AND WEIGHTS

21

TEMPERATURE, HUMIDITY AND ALTITUDE

22

MEDIA ENVIRONMENTAL CHARACTERISTICS

23

SHOCK AND VIBRATION

23

AC POWER REQUIREMENTS

24

AC GROUND

24

AC POWER CORD

24

POWER SUPPLY OUT-OF-RANGE PROTECTION FEATURES

24

HEAT DISSIPATION

24

TILT RANGE

24

PARTICULATE LIMITS

25

WARNING LABELS

25

UNPACKING AND REPACKING INSTRUCTIONS

27

UNPACKING THE LD 8100

27

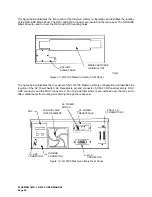

DESKTOP, RACK MOUNT AND LIBRARY CONFIGURATIONS

27

TOWER CONFIGURATION

29

INSPECTING THE LD 8100

31

REPACKING THE LD 8100

31

DESKTOP, RACK MOUNT AND LIBRARY CONFIGURATIONS

32

TOWER CONFIGURATION

34

INSTALLATION AND DE-INSTALLATION

35

INSTALLATION REQUIREMENTS

35

QUICK RELEASE RACK MOUNT KIT INSTALLATION

36

QUICK RELEASE RACK MOUNT DE-INSTALLATION

47

SCSI BUS CONSIDERATIONS

48

CONNECTING POWER AND SCSI CABLES

50

CONNECTING THE POWER CORD

50

CONNECTING MULTIPLE DEVICES

50

CONNECTING A SINGLE DEVICE

51

CONNECTOR VERIFICATION

52

Summary of Contents for LD 8100

Page 1: ...THE PLASMON 8000 SERIES LD 8100 OPTICAL DISK DRIVE P N 9662915 B USER MANUAL ...

Page 6: ......

Page 26: ...PLASMON LMS LD 8100 USER MANUAL Page 26 ...

Page 86: ...PLASMON LMS LD 8100 USER MANUAL Page 86 ...

Page 105: ......