6/24

Attention: The actuation path of the release button must always be kept clean.

Since dirt or chemical products could compromise the device operation.

4.2 Positioning the cable

The sheath of the actuation cable must be fixed to the profile or to the wall with collars,

or by similar means, at intervals not to exceed 500 mm.

The cable sheath must be stable and must not shift when the device is being used.

Be sure to leave enough play between the outer sheath and the collars, so that the

cable can slide freely inside.

Attention: The positioning of the cable with a bending radius of less than 100

mm is not allowed. Avoid running the cable in profiles or walls that require excessive

changes of direction; a maximum of four bends of 90° each are allowed.

4.3 Inserting the cable into the push button

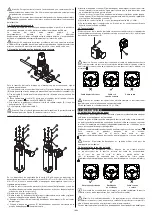

A

B

C

D

E

Follow these steps to insert the Bowden cable into the actuation mechanism.

1) With the button not activated, slide the cable (C) through the hole in the setting

adjuster (B) until it comes out through the hole on the actuation lever (D).

2) Pull the cable (C) until the protective sheath (A) enters the base of the setting

adjuster (B).

3) Lightly apply tension to the cable (C) until the square which is located in the

connection block displays the symbol (see CABLE TENSIONING paragraph).

4) Fasten the cable to the lever by screwing the threaded stud screw (E) with a

tightening torque of between 1.2 and 1.5 Nm.

5) Cut off the surplus cable C.

Attention: For the mechanism to function correctly, the excess cable length from

the fixing point (D) must be less than 5 mm.

4.4 Installation on series NS switches (only for articles VN RR-K1)

A

B

C

E

D

A

B

C

E

F

In NS series safety devices that are already equipped with a front or rear release

device (articles NS ••ST•••• ,NS ••SE••••, NS ••CE•••• and NS ••CT••••), the remote

escape release can be installed by the user according to the following procedure.

1) Remove the four protection caps (A) from the switch head using a small flathead

screwdriver, taking care not to damage them, for subsequent reuse.

2) Remove the 4 fixing screws (B).

3) Remove the cover (C) of the switch head by lifting it upwards, taking care not to

damage the locking pins (E) inside.

4) Remove the entire escape release button (D) from the body of the switch.

5) Set the connection block (F) of the remote escape release to the unlocked position

by pulling the cable.

6) Insert the connection block (F) of the remote escape release into the switch, exer-

ting a slight pressure, until the sealing gasket is properly positioned.

7) Reposition the cover (C) on the switch head, and check that the locking pins (E)

are correctly positioned in place, so that they prevent movement of the connection

block (F).

8) Tighten the four screws (B) with a tightening torque of between 0.8 and 1.2 Nm.

9) It is recommended that the screw holes be closed with the four plugs (A) to avoid

the accumulation of dirt.

4.5 Tensioning the cable

The cable tension can be fine-tuned using the appropriate setting adjusters located on

the mushroom button (A) or on the switch connection block (B).

A

B

Attention: For proper operation when the button is not activated, the cable

must be put under tension until the indicator square in the switch connection block

is positioned in the centre of the arc which indicates the correct tension with the

symbol.

Attention: At the end of the operations, always tighten the lock nut of the settings

adjuster to prevent subsequent slackening of the cable.

Lock nut tightening torque between 1.2 and 1.5 Nm.

5 OPERATION

5.1 Activation and reset of the button

The remote escape release allows personnel who become accidentally trapped to exit

dangerous areas of the machine.

When the remote escape release is pressed, it acts on the locking mechanism of the

safety switch via the connection cable, causing the immediate release of the actuator

regardless of the condition of the safety switch.

The square indicator, which is located in the connec-

tion block on the switch, is positioned at the symbol.

To reset the button after an actuation, pull it outwards to the limit of travel.

The square indicator, which is located on the connection block on the switch, is posi-

tioned at the symbol.

Attention: The release button must not be used as a machine emergency stop.

5.2 Automatic monitoring of the cable tension

The remote escape release is equipped with a mechanical sys-

tem for automatic monitoring of the correct actuation cable tension.

In the event that the cable is cut or loses too much ten-

sion, the safety switch stops the machinery under safe conditions.

The square indicator, which is located in the connection block on the switch, is posi-

tioned at the symbol.

If the actuation cable is intact, the correct tension can be restored via the settings

adjusters (see Cable Tensioning paragraph).

Attention: If the actuation cable is damaged, or the settings adjusters are not

sufficient to restore the correct tension, the entire device must be replaced. Do not

open the connection block to the switch to attempt repairs.

For NS series switches, a new remote escape release button (article VN RRK1) can

be ordered and replaced by carefully following these operating instructions.

For NG series switches, the entire device must be sent for repair. Please contact

technical assistance for more information (see SUPPORT paragraph).

6 INSTRUCTIONS FOR PROPER USE

6.1 Installation

- The release button must be clearly visible from inside the machine.

- Button activation must be easy, immediate and independent from the machine

operating status; to help you recognise the button and explain its function, identification

stickers are available in various languages (contact the sales department for detailed

information).

Cable too tight

Cable loosened

Cable at

correct tension

Release activated

Cable cut

or loosened

Release

not activated