5/24

Pizzato Elettrica Srl

via Torino, 1

36063 MAROSTICA (VI)

ITALY

e-mail: [email protected]

web site: www.pizzato.com

Phone: +39.0424.470.930

ZE FOG146A21-EU

1 INFORMATION ON THIS DOCUMENT

1.1 Function

These operating instructions provide information on installation, connection and safe

use for the following articles:

VN RR-K•, NG •D8•••••, NG •D9•••••, NS •••R••••.

1.2 Target audience

The operations described in these operating instructions must be carried out by

qualified personnel only, who are fully capable of understanding them, and with the

technical qualifications required for operating the machines and plants in which the

safety devices are to be installed.

1.3 Application field

These operating instructions apply exclusively to the products listed in paragraph

Function, and their accessories.

1.4 Original instructions

The Italian language version is the original set of instructions for the device. Versions

provided in other languages are translations of the original instructions.

2 SYMBOLS USED

This symbol indicates any relevant additional information

Attention: Any failure to observe this warning note can cause damage or

malfunction, including possible loss of the safety function.

3 DESCRIPTION

3.1 Device description

The device to which these operating instructions refer is an accessory designed and

built to be installed on Pizzato Elettrica NG and NS series safety locking switches.

The remote escape release facilitates remote unlocking of the safety switch in cases

where traditional release devices (lock type, screwdriver type, push button type, etc.)

are not easily accessible due to the configuration of the machinery.

The release button and the safety switch are mechanically connected via a Bowden-

type metal cable.

The remote escape release is equipped with a safety mechanism which causes the

machine to stop immediately and safely in the event that the cable should break or

become loose.

The remote escape release for the NG series articles can only be supplied

as already installed on the safety switch (articles NG •D8••••• and NG •D9•••••) and

cannot be removed by the user.

The remote escape release for the NS series articles can be supplied as already

installed on the safety switch (articles NS ••• R ••••), or it can be mounted as an

accessory (article VN RR-K1) on all devices that allow for its installation (articles

NS ••ST••••, NS ••SE••••, NS ••CE••••, NS ••CT••••).

Attention: The installation of the VN RR-K• accessory on series NS devices with

an energised solenoid working principle is prohibited (articles NS E•••••••, NS H•••••••,

NS M•••••••).

3.2 Intended use of the device

- The device described in these operating instructions is designed to be applied on

industrial machines for state monitoring of movable guards.

- The direct sale of this device to the public is prohibited. Installation and use must be

carried out by qualified personnel only.

- The use of the device for purposes other than those specified in these operating

instructions is prohibited.

- Any use other than as expressly specified in these operating instructions shall be

considered unintended by the manufacturer.

- Also considered unintended use:

a) using the device after having made structural, technical, or electrical modifications

to it;

b) using the product in a field of application other than as described in paragraph

TECHNiCAL DATA.

4 INSTALLATION INSTRUCTIONS

Attention: Installing a protective device is not sufficient to ensure operator

safety or compliance with machine safety standards or directives. Before installing a

protective device, perform a specific risk analysis in accordance with the key health

and safety requirements in the Machinery Directive. The manufacturer guarantees

only the safe functioning of the product to which these operating instructions refer, and

not the functional safety of the entire machine or entire plant.

Please see the operating instructions for NS and NG series safety devices for

the applicable installation instructions.

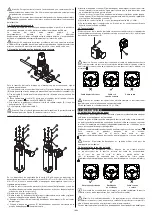

4.1 Fixing the push button

The push button for the remote escape release can be fixed to the outside or inside

of the profile or of a wall.

Fixing to the outside of the profile

Fixing to the inside of the profile

4.1.1. Fixing to the outside of the profile

A

B

C

D

E

F

G

H

a

b

A = Internal mechanism. B = M5 screws (not supplied). C= Outer plastic cap.

D = Fixing profile. Distance a = 19 mm. Distance b = 50 mm. E = Descriptive label

(sold separately).

F = lock nut. G = mushroom button. H = sliding bolt

Attention: Always fix the device with 4 screws. Always use M5 flat-bottom screws

with a resistance class of 4.6 or higher. Install the screws with medium resistance

thread lock, and a number of threads engaged equal to or greater than the screw

diameter. The device must never be fixed with less than 4 screws.

1) Fix the internal mechanism (A) to the machine profile (D). The tightening torque of

the M5 screws (B) must be between 2 and 3 Nm.

2) Fix the actuation cable to the internal mechanism (see paragraph iNSERTiNG THE

CABLE iNTo THE PuSH BuTToN).

3) Attach the outer cap (C) with snap-on coupling.

4) Affix the optional label with the description of the control (E).

5) Put the lock nut (F) on with a tightening torque of between

2 and 3 Nm.

6) Screw the mushroom button (G) onto the sliding bolt (H) with a tightening torque of

between 4 and 5 Nm. During the operation, hold the sliding bolt (H) with a spanner

in order to avoid twisting the sliding bolt (H)

4.1.2. Fixing to the inside of the profile

A

B

C

D

E

F

A = Internal mechanism. B = Fixing profile with Ø 22 mm hole according to

EN 60947-5-1.

C = Descriptive label (sold separately). D = lock nut. E = mushroom

button.

F = sliding bolt.

1) Insert the internal mechanism (A) into the perforated profile (B).

2) Fix the actuation cable to the internal mechanism (see paragraph iNSERTiNG THE

CABLE iNTo THE PuSH BuTToN).

3) Insert the optional label with the description of the control (C).

4) Put the lock nut (D) on with a tightening torque of between

2 and 3 Nm.

5) Screw the mushroom button (E) onto the sliding bolt (F) with a tightening torque of

between 4 and 5 Nm. During the operation, hold the sliding bolt (F) with a spanner

in order to avoid twisting the sliding bolt (F)

Attention: A distance of between 10 and 35 mm must be maintained between

the push button and the wall from which the button protrudes in order to guarantee

correct operation and easy resetting.