L80-029 Rev 5 10/07 8

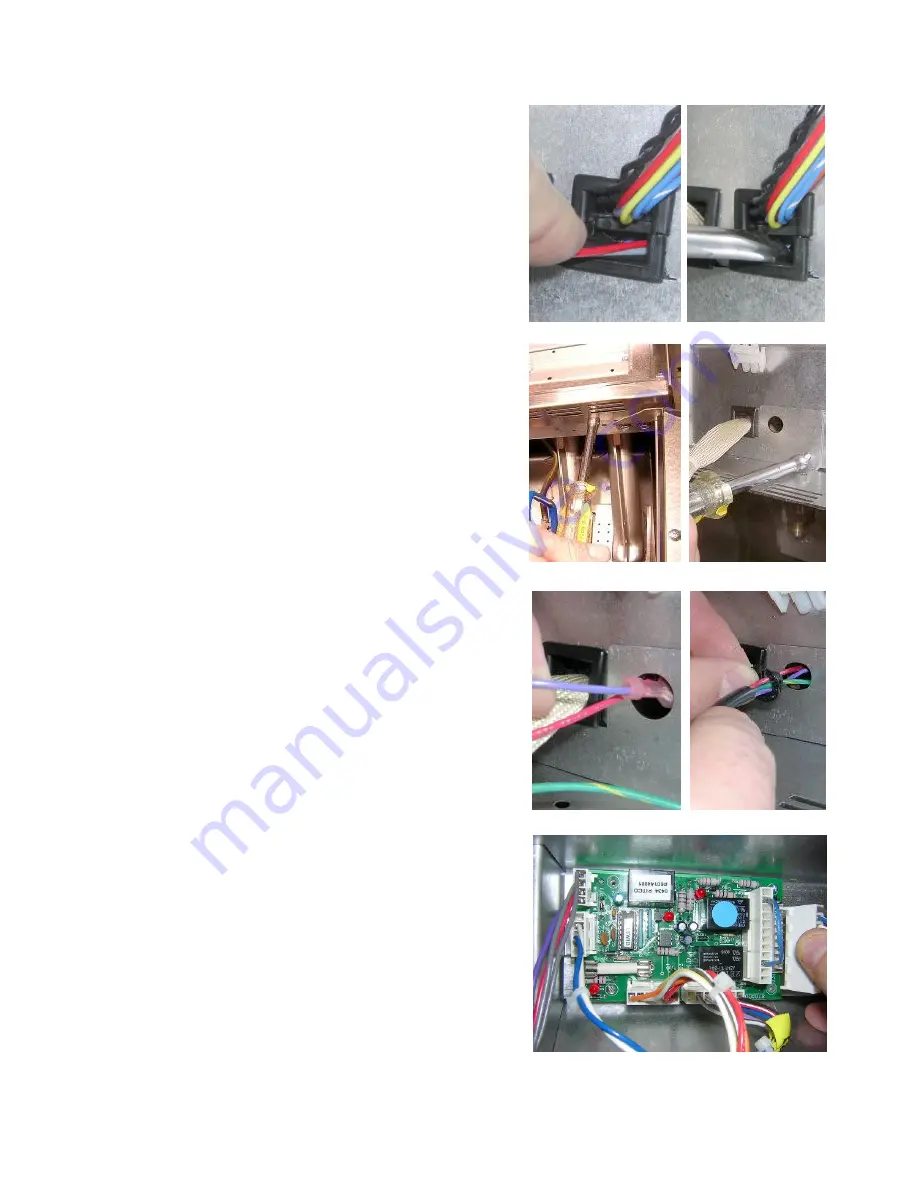

e. If the appliance you are upgrading does NOT have a

Solid State Control, proceed to step f in this section.

If the appliance that you are upgrading has a Solid

State Control, feed the other ends of the SCBS

Harness through the unused portion of the strain

relief holding the Solid State Control Harness and

proceed directly to step h in this section.

NOTE:

If needed, you can carefully nudge open the

area in the strain relief with a screwdriver to make

additional room to insert the SCBS harness. Take

care not damage the harness during this procedure.

f.

Using a 5/16 nut driver, remove the two screws on

the underside of the front panel that hold the slotted

bottom on. Remove the slotted front panel bottom;

this will allow easier access to the cable retainer

plate. Remove the two screws holding the cable

retainer plate onto the appliance and remove the

cable retainer plate, leaving the control cable held in

place by the square strain relief. Replace the cable

retainer plate that you removed with the new one

provided in the kit. Cable retainer plate style varies

from model to model; the one that came with your kit

should look exactly like the one that you removed

with an added hole.

g. Feed the SCBS harness through the hole in the cable

retainer plate. Collect and capture all wires in this

harness into the split grommet provided with the kit

and install the grommet into hole in the cable retainer

plate. The installation of the grommet is critical as it

insures that the wires will not chafe and/or short out

against the metal edge of the hole in the cable

retainer bracket.

h. You may now reconnect the main control harness to

the SCBS board exactly as it was connected to the

previous board, re-attach the front panel bottom and

reconnect, remount and close up the front panel

assembly.

Summary of Contents for L80-029

Page 15: ...13 L80 029 Rev 5 10 07 ...

Page 16: ...L80 029 Rev 5 10 07 14 ...

Page 17: ...15 L80 029 Rev 5 10 07 ...

Page 18: ...L80 029 Rev 5 10 07 16 ...

Page 19: ...17 L80 029 Rev 5 10 07 ...

Page 20: ...L80 029 Rev 5 10 07 18 ...

Page 21: ...19 L80 029 Rev 5 10 07 ...

Page 22: ...L80 029 Rev 5 10 07 20 ...