Technical Manual

MT 188-E

8

Wdsu

= tripping range due to slam-shut valve pressure decrease,

which can be obtained by using the setting spring mounted during final

testing.

Wdu

= tripping range due to slam-shut valve pressure decrease, which

can be obtained by using the setting springs listed in the tables.

4.2

GAS FEEDING, CHECK OF EXTERNAL

TIGHTNESS AND CALIBRATIONS

Pressure feeding to the equipment shall be performed very slowly.

When not any inertization procedure is implemented, it is

recommended to keep gas speed in the feeding piping under a value of

5 m/sec during the pressure feeding phase.

In order to prevent the equipment from being damaged, the following

shall be absolutely avoided:

- Pressurization through a valve positioned downstream of the

equipment itself.

- Depressurization through a valve positioned upstream of the

equipment itself.

The external tightness is assured when by applying a foam medium on

the element under pressure no bubbles are produced.

Usually, the slam-shut valves are supplied already calibrated to the

requested value. However, it may happen that due to several reasons

(e.g. vibrations during transport) the calibrations may be subject to

slight changes, though remaining within the range of the values

allowed by the springs used. Therefore, it is advisable to verify the

calibrations according to the procedures outlined here below.

Before commissioning the valve, it is necessary to verify that all

on/off valves (inlet, outlet, and bypass - if any) are closed and that

the gas has such a temperature as not to create malfunctions.

4.3

CALIBRATION CHECK

Check and record the tripping of the slam-shut device as follows:

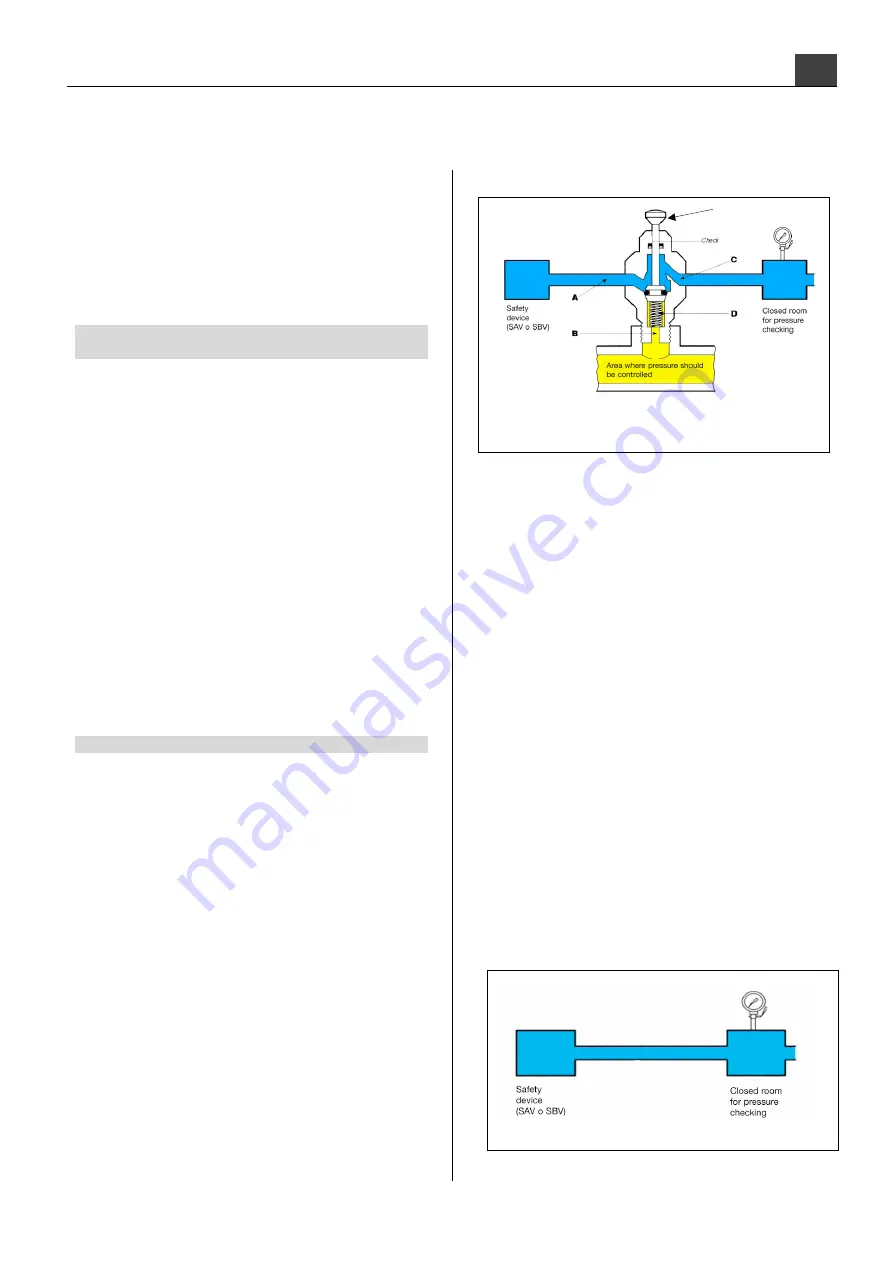

A) For the slam-shut devices connected to the downstream piping

through the "push" three-way switch valve, proceed as follows

(Fig. 10):

Fig. 10

- connect to the way C a controlled auxiliary pressure;

- restore the slam-shut device by means of the suitable lever;

- press knob 1 and:

•

For safety devices tripping in case of maximum pressure slowly

increase the auxiliary pressure and verify the tripping value.

If necessary, increase the tripping value by rotating clockwise

the adjustment ring nut or decrease the tripping value by rotating

it counter-clockwise.

•

For safety devices tripping in case of pressure increase and

decrease, slowly increase the auxiliary pressure and record the

tripping value.

If necessary, increase the tripping value by rotating clockwise

the adjustment ring nut or decrease the tripping value by rotating

it counter-clockwise.

Decrease the auxiliary pressure and perform the device

restoration procedure.

Slowly decrease the auxiliary pressure and verify the tripping in

case of pressure decrease. If necessary, increase the tripping

value by rotating clockwise the adjustment ring nut or decrease

the tripping value by rotating it counter-clockwise.

- make sure that the operation is fine by repeating the procedure for at

least 2-3 times.

- disconnect the controlled auxiliary pressure from way C;

B) For the devices not equipped with "push" valve, it is recommended

to connect separately the control head at a controlled auxiliary

pressure and repeat the operations described above (Fig. 11).

Fig. 11

fig.