phytron

33

MA 1249-A009 EN

When the MCC-1 is connected to the PC by USB-interface, USB drivers

have to be installed on the PC. You´ll find the driver on the delivered

Phytron CD.

Administrator authorizations are required for the driver installation.

Only use an USB cable with a maximum length of 2 m!

Use the same USB Serial Port on the PC, when you want to check

several USB Devices constructed in the same way. So the COM Port

number won´t change.

6.5.2 Ethernet Interface

The MCC-1

can be integrated into the firm’s network by the Ethernet adaptor.

The port number of the MCC-1 controller is fixed to 22222 by Phytron.

IMPORTANT:

The controller obtains its IP address over DHCP exclusively.

(dynamical IP configuration in every subnet)!

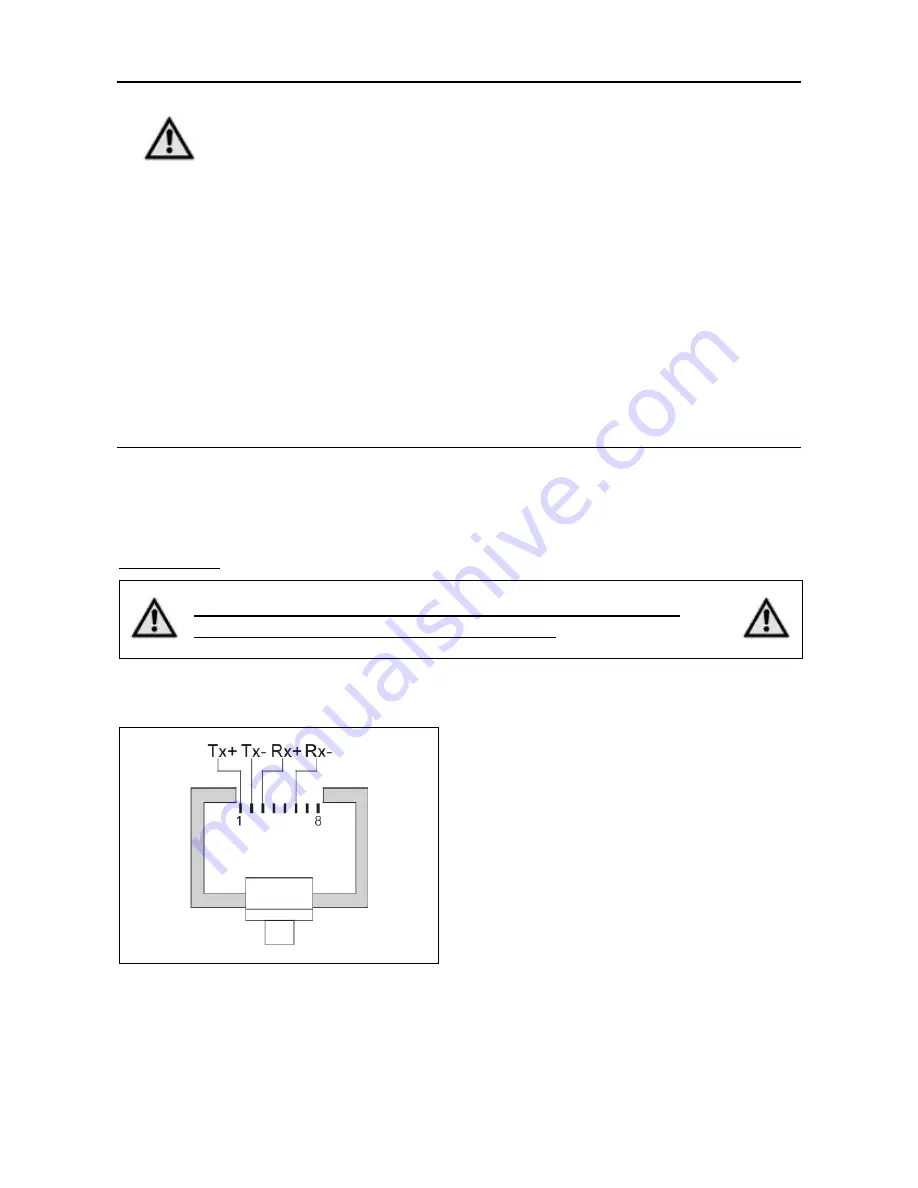

The Ethernet connection via RJ 45 connector (X5 Com):

Abb. 1:

X5: RJ 45 Ethernet connector