CF CRIMPHANDY

8

PHOENIX CONTACT

105555_en_07

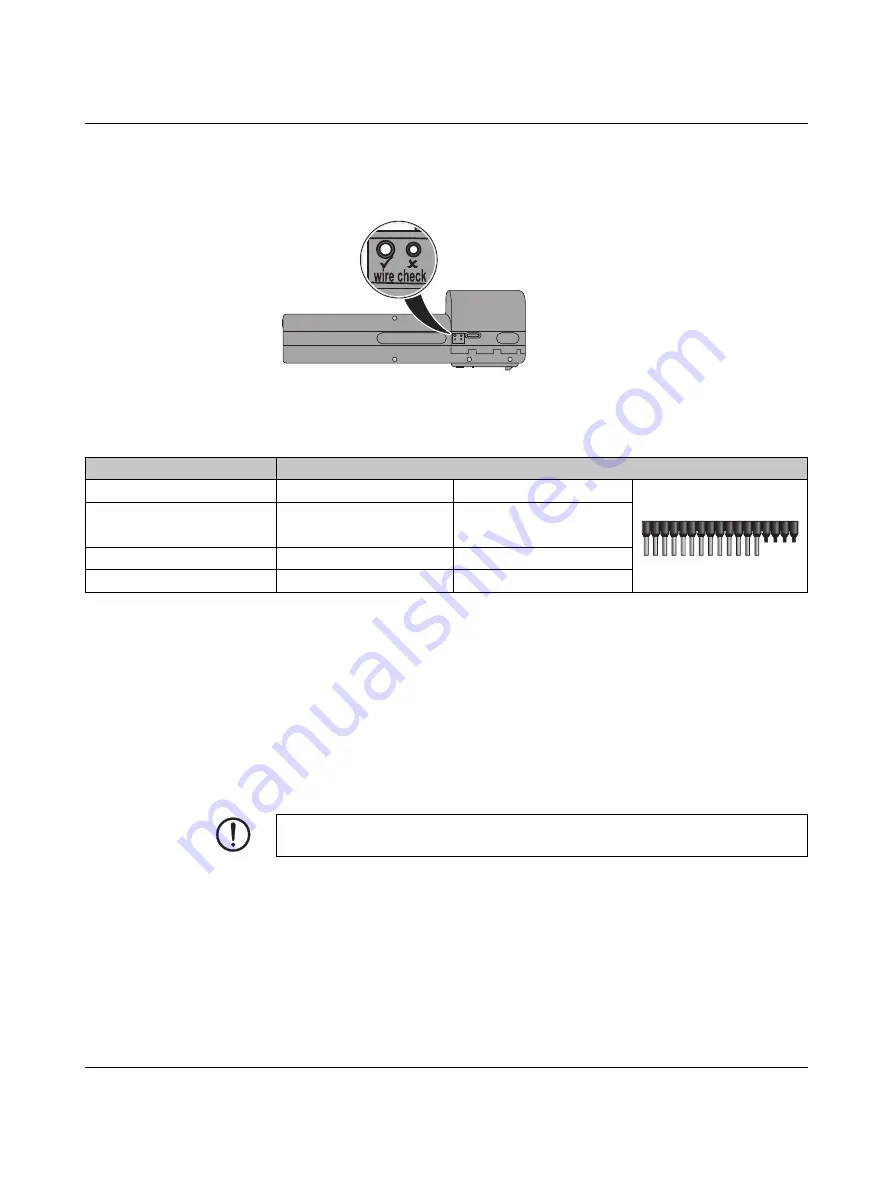

Wire check

For checking the outside conductor diameter, the mobile crimping tool has two openings

that are labeled "wire check". The conductor has to fit in the opening that is labeled with the

checkmark. If the conductor fits in the small opening with the cross, then it may not be used.

Conductors that are too thick or too thin cause the crimping tool to be damaged.

Figure 1-1

Checking the outside diameter of the conductor

Suitable ferrules

Only use taped ferrules from Phoenix Contact that have a specific function end. This special

design is required for safe operation.

Preparing the conductor

In order to ensure optimum operation of the portable crimping tool, the conductor must be

prepared correctly. Make sure that the conductors are always cut straight. Conductors that

have been squeezed, cut at an angle or already stripped must not be used. Even for very

short conductors it may happen that they are not crimped correctly.

Only use cable cutters with sharp blades which cut the conductors and do not squeeze

them. Do not use diagonal cutters or similar unsuitable tools.

Quality of the crimping re-

sult

The quality of the crimping result depends on:

–

The stranding of the conductor

–

The processing temperature

–

The tolerance at the cross section

wire check

Device type

Taped ferrules from Phoenix Contact

CF CRIMPHANDY 0,5

AI 0,5-8 WH-S,

1212521

AI 0,5-8 OG-S,

1212784

CF CRIMPHANDY 0,75

AI 0,75-8 GY-S,

1212522

AI 0,75-8 BU-S,

1212785

AI 0,75-8 WH-S,

1212783

CF CRIMPHANDY 1,0

AI 1,0-8 RD-S,

1212523

AI 1,0-8 YE-S,

1212782

CF CRIMPHANDY 1,5

AI 1,5-8 BK-S,

1212524

AI 1,5-8 RD-S,

1212781

NOTE:

The user has to make sure that only suitable materials are used.

Summary of Contents for 1212463

Page 2: ......

Page 36: ...CF CRIMPHANDY 36 PHOENIX CONTACT 105555_en_07 ...