Circuit Diagrams and PWB Layouts

EN 35

FHP PDP

7.

7.

Circuit Diagrams and PWB Layouts

Not applicable.

8.

Alignments

Index of this chapter:

8.1 Voltage Setting Procedure

8.1

Voltage Setting Procedure

On the back of the PDP, in the top right hand corner, you find the Voltage Setting label:

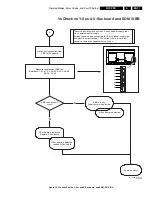

Figure 8-1 Voltage setting label

This Voltage Setting label shows the following messages:

Table 8-1

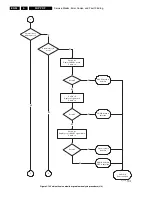

If the voltage adjustments Vs and Va on the Power Supply Unit must be performed, depends on the version of the Power Supply Unit (see

table 8-2).

Table 8-2

This table also shows if the Vs and Va control loop must be switched ON or OFF.

The voltage adjustments Vw and Vx are done automatically via ComPair. After exchange of the Logic Board, click on ‘Ship out’. The settings

from the old Logic Board will be restored in the new Logic Board.

Item

Adjustment items

Measurement point

Adjustment value (conditions)

1

Vs voltage adjustment

PSU board F241 or CN392 test points

Voltage setting label indication value* ± 1% (all black)

2

Va voltage adjustment

PSU board F240 or CN392 test points

Voltage setting label indication value* ± 1% (all black)

3

Vw voltage adjustment

X-SUS board connector CN26 6-pin

Voltage setting label indication value* ± 1% (all black)

4

Vx voltage adjustment

X-SUS board connector CN26 1-pin

Voltage setting label indication value* ± 1% (all black)

PSU version 3

PSU v3 with precision R's

PSU version 4

PDP with Vs feedback (-52 PDP)

Feedback loop 'OFF', alignment is necessary Feedback loop 'ON', alignment (check) is

necessary (see voltage setting label)

Feedback loop 'ON', no alignment necessary

PDP with Vs/Va feedback

(with 'B' in serial number)

Feedback loop 'OFF', alignment is necessary Feedback loop 'ON', no alignment (check)

necessary

Feedback loop 'ON', no alignment necessary

< LOT > NNNNNNNNNNNNNN

Vs = XX.X V

Va = XX.X V

Vw = XXX.X V

Vx = XX.X V

F_14582_016.eps

121005