70Xi Cold Flow Properties Laboratory Analyzer

User Guide

24

A p p e n d i x B .

C l e a n i n g & R o u t i n e M a i n t e n a n c e

Cleaning the LED Touch Screen and External Surfaces of the Analyzer

The screen protector shields the touch screen surface from dirt and spills while maintaining the screen’s

responsiveness and functionality. The screen protector film should be replaced every 6 months.

Clean the analyzer’s LED touch screen using a soft, lint-free cloth and lens cleaner solution containing a

mixture of alcohol and water. Gently wipe down the screen until any visible fingerprints, smudges, dust or

other signs of contaminants are gone.

Clean the external surface of the analyzer with a soft, damp cloth.

Routine Maintenance Schedule:

Every 300 Test Runs (or more frequently if necessary)

Replace Desiccant

Every 6 months:

Replace Screen Protector

Replace 12 months:

Replace Dryer Bottle O-ring

Replace Lid O-Ring

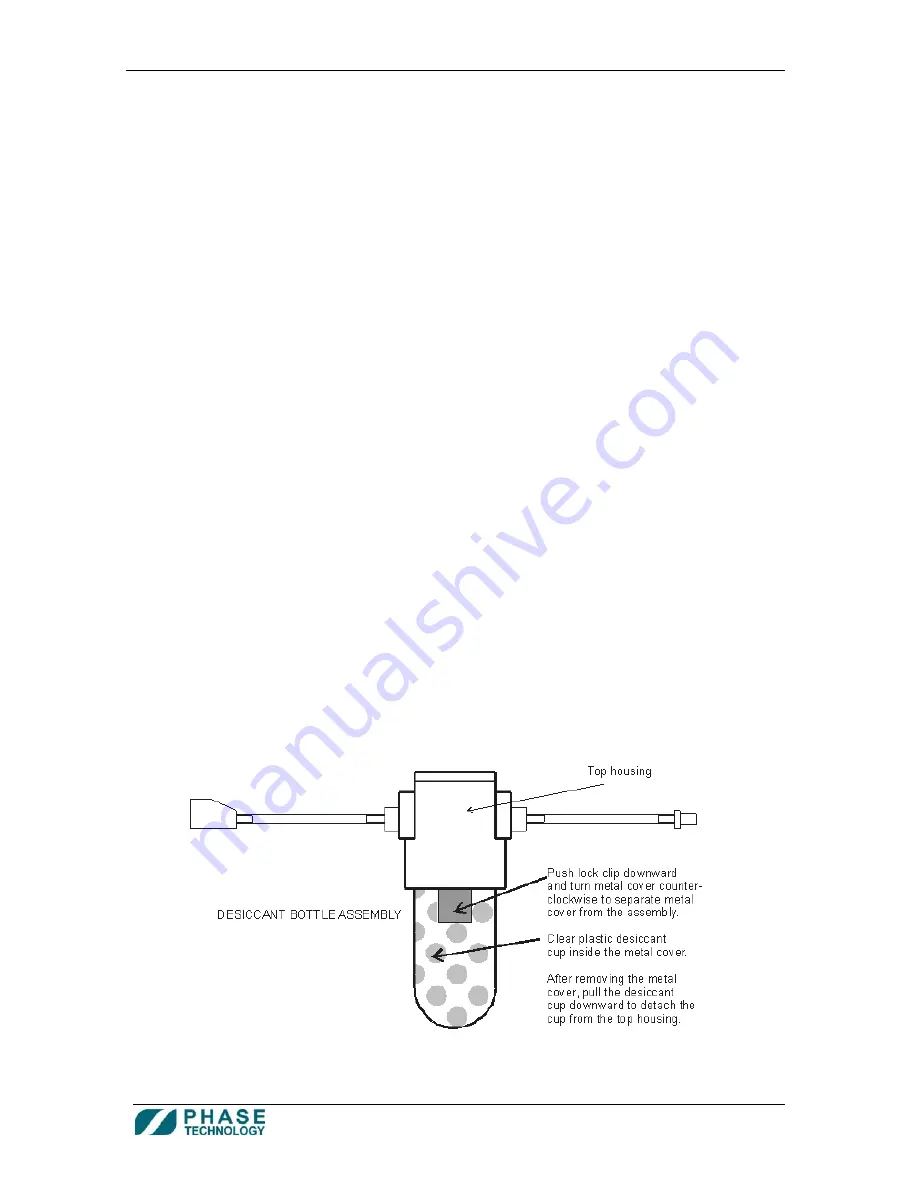

How to Replace the Desiccant:

1.

Turn off power to analyzer.

2.

Disconnect dryer bottle from back of analyzer by pressing the spring plates of both quick-connect

fittings and pulling them to separate.

3.

Keep the dryer bottle vertical (upright). Push the lock clip of the desiccant cup protector

downward and turn it to the left (counterclockwise) to separate the metal cover from the

assembly.

4.

Pull the desiccant cup downward to separate the bowl from the top housing.