5

3. Installation

3.1. Preparations For Installation

Do not carry out any unauthorised conversions

or alterations to the turbopump.

– The maximum permissible rotor temperature of the pump is

120 °C. If the vacuum chamber or parts in the vacuum

chamber are heated, the values stated in the technical

data relating to the level of heat which may be radiated

into the pump must not be exeeded. If necessary, suitable

shielding must be fitted in the vacuum chamber before the

turbopump (constructional suggestions available on

request).

– Only remove the blank flange from the high and for-vacu-

um side immediately before connection.

– The turbopumps must

not

be transported when filled with

lubricant.

– Where magnetic fields of > 13.4 mT are involved suitable

shielding must be provided (available on request).

– If the pump is baked out, the body of the pump must be

insulated to prevent burns from accidental contact.

– Both the TPH and TPU 2201 must be anchored to the

surface.

– In the event of a sudden standstill of the rotor, torques of

up to 8960 Nm can arise and these must be taken up by the

turbopump and frame. Pumps must be anchored as

follows:

– ISO flange with 6 bracket screws,

or

– CF flange with the complete set of M8 screws,

or

– underside of the pump with 6 screws M6,

screws quality 8.8.

3.2. Installing The Pump,

Connecting The High Vacuum Side

Important

The utmost cleanliness must be observed when fitting all high

vacuum parts. Unclean components prolong the pumping

time.

Use a splinter shield

The use of a splinter shield in the high vacuum flange protec-

ts the turbopump against foreign bodies coming from the

vacuum chamber but does reduce the volume flow rate of the

pump by approximately 15%. For fitting splinter shields please

refer to “Fitting the splinter shield”.

The high vacuum side can be flanged onto the vacuum cham-

ber either directly or via a bellows or a vibration compensator

(see ”Accessories”).

Connecting via bellows

If the high vacuum side is to be flanged via a bellows, the tur-

bopump must be secured for example via the holes on the

underside of the turbopump (please see dimensions). The

fastening must be able to withstand the torque referred to in

Section 3.1.

Connecting Via A Vibration Compensator

The maximum permissible temperature at the

vibration compensator is 100 °C.

Where a vibration compensator is in use, a freely suspended

turbopump can be flanged onto the vacuum chamber.

Additional protective casing must be provided to take up the

energy of the rotor in the event of a malfunction (please

discuss this question with the manufacturer).

The maximum loading capacity of the high vacu-

um flange is 3000 N (equivalent to 300 kg).

This does not apply to pumps with flanges on the

side or below.

Asymmetric loading on the high vacuum flange

must be avoided.

If a vacuum chamber is fitted to the high vacuum flange with-

out support, it must be ensured that no torque is transmitted

to the flange (asymetrical weight of the vacuum chamber).

Even with side and under flanges, pumps can be flanged to

the vacuum chamber with a freely suspended horizontal rotor

shaft. It is a pre-condition that the vacuum chamber be firmly

anchored.

No forces from the piping system must be

allowed to act on the pump where turbopumps

are anchored.

Suspend or support all pipes to the pump.

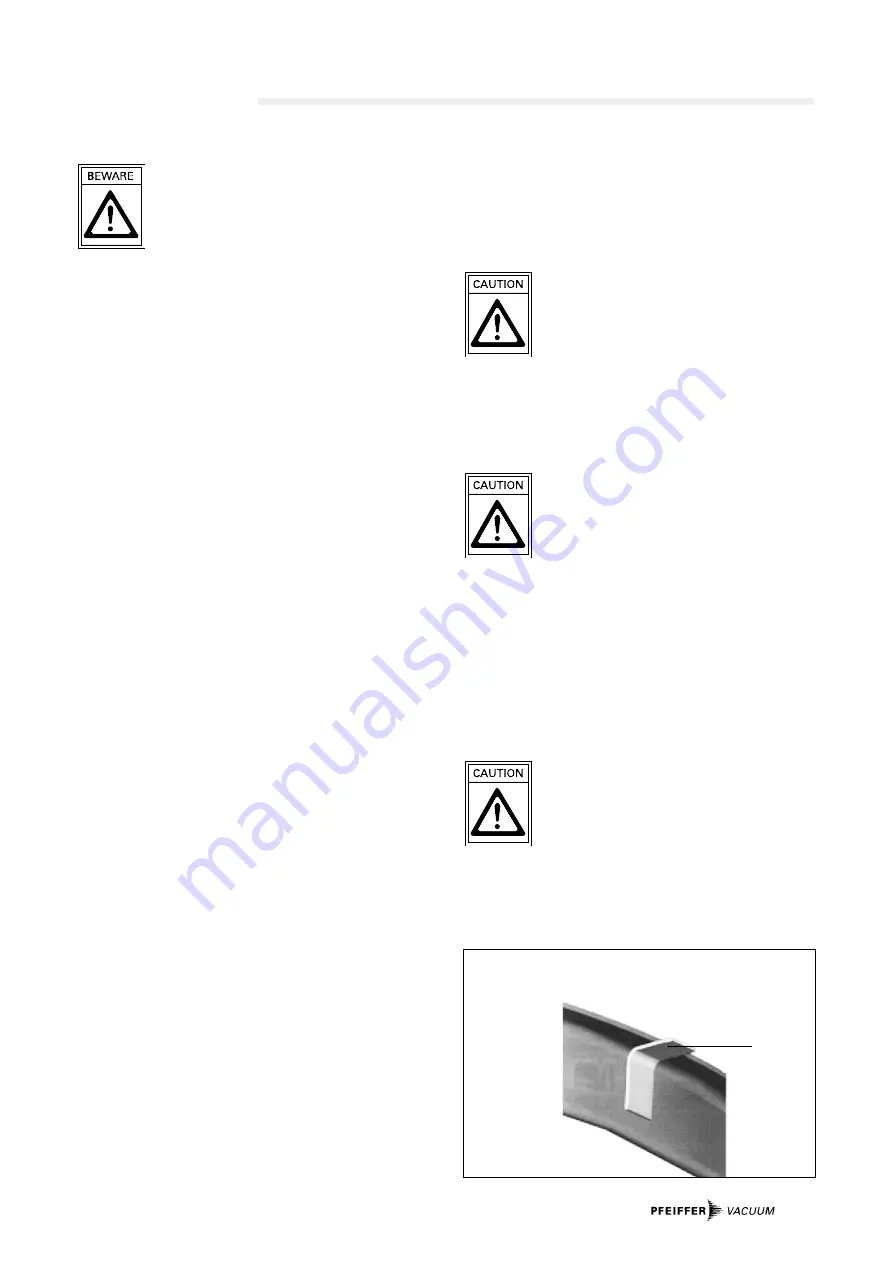

Fitting The Splinter Shield

➡

Insert the splinter shield in the ISO-K flange in condition on

delivery.

Inserting the splinter shield in ISO-K flage

A

Strap (Condition on delivery)

A

Summary of Contents for TPH 2201

Page 11: ...11 3 12 Connections Diagram 1 1...

Page 12: ...12 Connection Diagram For 3 phase Backing Pump...

Page 23: ...23 Spare parts...