11

Installation

Installation of ISO-K

flange with ISO-K

flange

For the installation of the flange connections the following components are avail-

able:

Î

Mind that the sealing surfaces are not damaged.

Î

Flange the turbopump according to the drawing and together with the compo-

nent parts in the mounting material kit.

Î

Use the required number of bracket screws.

Î

Tighten the bracket screws crosswise in three steps.

Î

Tightening torque: 5, 15, 25 ±2 Nm

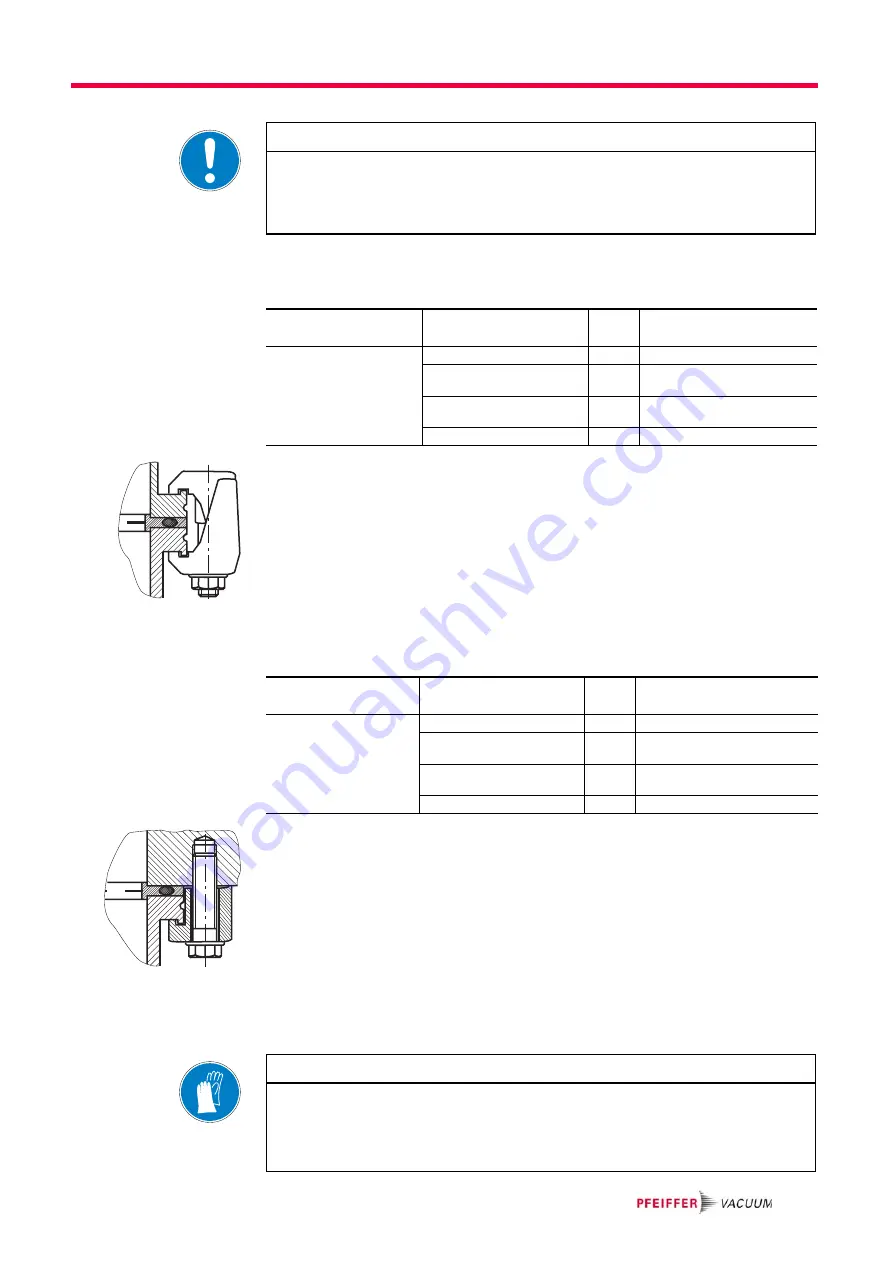

Installation of ISO-K

flange with ISO-F

flange

For the installation of the flange connections the following components are avail-

able:

Î

Mind that the sealing surfaces are not damaged.

Î

Flange the turbopump according to the drawing and together with the compo-

nent parts in the mounting material kit.

Î

Use 8 claw grips.

Î

Tighten the claw grips crosswise in three steps.

Î

Tightening torque: 3, 10, 16 ±1 Nm.

Installation of CF-

flanges

NOTE

Possible damage to the pump

If a pump with an ISO-K flange is fastened to a vacuum chamber with an ISO-F flange

or if ISO-KF flanges are used, sudden blocking of the rotor can result in twisting

despite proper installation.

Connection nominal

diameter

Designation

Pieces Ordering No.

DN 100 ISO-K

Centering ring (coated)

1

PM 016 210-U

Centering ring (coated) with

splinter shield

1

PM 016 211-U

Centering ring (coated) with

protective screen

1

PM 016 212-U

Bracket screw

6

PF 300 110-T

Connection nominal

diameter

Designation

Pieces Ordering No.

DN 100 ISO-K

DN 100 ISO-F

Centering ring (coated)

1

PM 016 210-U

Centering ring (coated) with

splinter shield

1

PM 016 211-U

Centering ring (coated) with

protective screen

1

PM 016 212-U

Claw grip

8

PF 301 100-T

NOTE

Preservation of sealing capacity

Observe the following to preserve sealing capacity:

Î

Touch seals only with gloves.

Î

Make sure sealing lips are undamaged.