Malfunctions

37

9

Malfunctions

Please note the following instructions should the pump malfunction:

9.1

Rectifying malfunctions

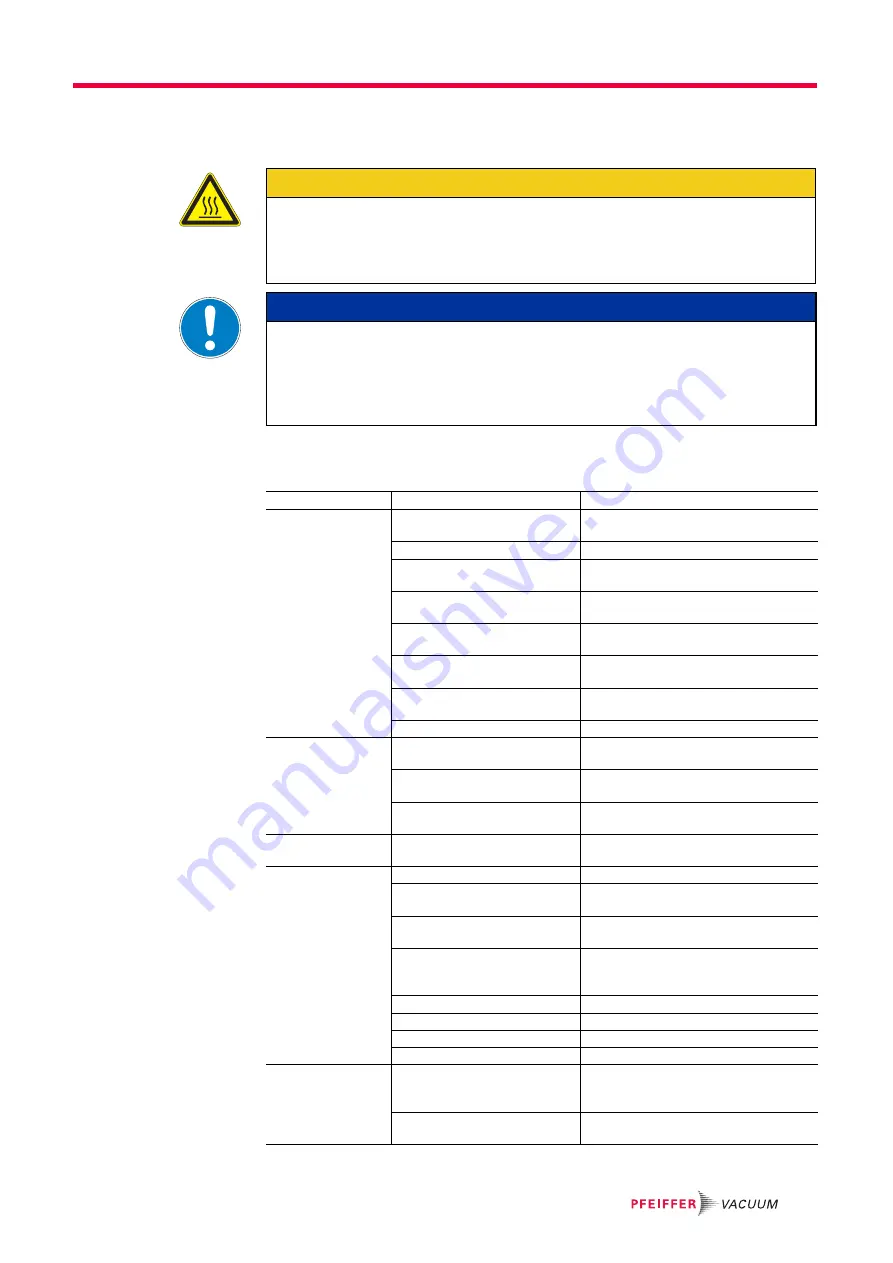

CAUTION

Hot surface!

Danger of burns if hot parts are touched. The surface temperature of the pump may rise

above 105 °C in case of malfunction.

Carry out work on the pump only after it has cooled to a safe temperature.

NOTICE

Motor overload!

Depending on the malfunction (e.g. blocking during cold start), the motor may not be

sufficiently protected by the built-in thermal protection switch from damage through

overheating.

Implement an additional network safety device.

Problem

Possible causes

Remedy

Pump will not start up No mains voltage or voltage does

not correspond to the motor data

Check mains voltage and mains fuse protec-

tion; check motor switch

Ambient temperature too low

Warm up pump to > 12 °C

Suction chamber not flooded

Flood on suction side after switching off

pump

Thermal cut-off switch has re-

sponded

Detect and fix cause of overheating; allow

pump to cool off if necessary.

Defective motor cut-off switch

(building side)

Re-set or replace switch.

Dirty pump system

Clean pump; notify Pfeiffer Vacuum service

department, if necessary.

Damaged pump system

Clean and overhaul pump; notify Pfeiffer

Vacuum service department, if necessary.

Motor defective

Replace motor

Pump switches off af-

ter a while after being

started

Thermal protection switch of the

motor has responded

Detect and fix cause of overheating; allow

pump to cool off if necessary.

Mains fuse protection triggered

due to overload (e.g. cold start)

Warm up pump

Exhaust pressure too high

Check opening of exhaust line and exhaust

accessories

High increase in oper-

ating temperature

Fault in cooling water circuit

Check flow paths for dirt and lime deposits;

clean, if necessary.

Pump not achieving

the ultimate pressure

Leak in the system

Fix leak

Falsified measuring result

Check gauge, test ultimate pressure without

connected system.

Pump or connected accessories

dirty

Clean pump and check components for dirt.

Dirt in operating fluids

Operate pump for a longer period of time

with opened gas ballast valve or replace op-

erating fluids

Gas ballast valve is open

Close valve.

Silencer is open

Set/adjust the silencer

Operating fluids fill level too low

Fill up operating fluids

Pump is damaged

Contact Pfeiffer Vacuum Service.

Pumping speed of

pump too low

Intake line not well-dimensioned

Keep connections as short as possible and

see that cross-sections are sufficiently di-

mensioned

Exhaust pressure too high

Check opening of exhaust line and exhaust

accessories