Adjustment

11 - 1

11

Adjustment

On the

PFAFF 1051, 1053, 1181

and

1183

do not use a screw clamp on the

needle bar! The special coating of the needle bar could be damaged.

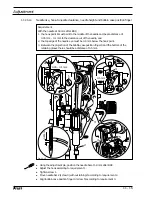

The illustrations in this chapter show the PFAFF 1053. Special attention is

drawn to differences which apply to other machine types.

11

.01

Notes on adjusting

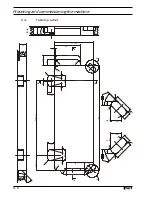

All adjustments in these adjustment instructions are based on a completely installed

machine and must only be carried out by appropriately trained specialists. Covers on the

machine which sometimes have to be removed and replaced for checks and adjustment

work are not mentioned here. The screws and nuts in brackets () are attachments of

machine parts which are to be loosened before making the adjustment and tightened again

after the adjustment has been carried out.

11

.02

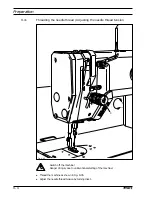

Tools, gauges and other accessories for adjusting

●

1 set of screwdrivers with blade widths from 2 to 10 mm

●

1 set of wrenches with jaw widths from 7 to 14 mm

●

1 set of Allan keys from 1.5 to 6 mm

●

1 metal rule, (Part No. 08-880 218-00)

●

1 feed dog adjustment gauge, Part No. 61-111 639-71

●

1 adjustment pin (5 mm dia.), Part No. 13-033 346-05

●

Adjustment gauge, part No. 61-111 639-70

●

Sewing thread and test material

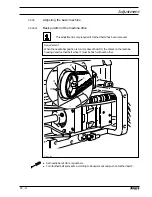

11

.03

Abbreviations

TDC = top dead center

BDC = bottom dead center