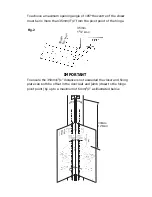

DOOR CLOSERS FITTED

TO A FIRE DOOR.

• Perko Powermatic,

®

conforms to

Power Size 3 of Controlled Door

Closing Device Standard BS

EN1154:1997 when the power

latching action is set to

maximum.

• Turn adjuster screw fully to

positive (+) as explained in 9.

• Closer must be fitted no more

than 750mm/30” from floor and

within 300mm/12” of a hinge.

• Closer and plates should be

bedded in Alfacryl FR Intumescent

Acrylic Mastic available from

Samuel Heath.

• Ensure door is plumb, hinges are

free, and that timber is sound.

• Take template provided and fold

along center line. Open door to 90º.

• Secure template to door edge and

frame edge within 300mm/12” of a

hinge ensuring the center line is

central in line with the pivot point of

the hinge.

• Draw a vertical line at the center

point of the door edge on the

template.

N

NB

B

T

Th

hiiss lliin

ne

e m

mu

usstt n

no

ott e

exxcce

ee

ed

d

3

35

5m

mm

m//1

1

3

3

//

8

8

”

” ffrro

om

m tte

em

mp

plla

atte

e cce

en

nttrre

e

lliin

ne

e..

SSe

ee

e FFiig

g.. 2

2

1

IMPORTANT NOTICE

• Repeat this vertical line onto

the frame side at the same

distance from centre line.

• At each point on the

template where the vertical

lines cross the horizontal

dotted lines mark through the

template using a bradawl into

the door edge and frame edge

to establish drilling points.

Remove template RETAIN FOR

REFERENCE.

• Note: Door can now be

removed from frame to assist

drilling if preferred.

2

TEMPLATE POSITIONING

Fig. 1

FRAME

300mm

12” MAX

DOO

R

/